- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Have you ever drilled into concrete, only to find your screw slips or fails to hold? Picking the correct screw can make all the difference. If you grab a concrete screw that’s too short, misalign your holes, or skip cleaning the surface, your project might not last. You want a screw that matches your needs, holds strong, and stands up to daily wear. This guide will help you avoid those common pitfalls.

Choose the right concrete screw to keep your project strong, safe, and long-lasting.

Match screw type and size to your load, material, and environment for the best hold.

Use corrosion-resistant screws like stainless steel for outdoor or wet areas.

Pre-drill holes with the correct drill bit size and clean out dust before installing screws.

Avoid common mistakes by checking load, size, and corrosion, and never reuse screws in the same hole.

When you work with concrete, safety comes first. Picking the correct screw can keep your project strong and secure. If you use the right screw, you help your structure stay stable and reliable. You want your shelves, railings, or fixtures to hold up, even when people lean or pull on them. The correct screw keeps everything in place, even if the load changes or the concrete cracks.

The right screw gives you better holding power and helps prevent accidents.

You need to match the screw to the load it will carry and the type of cement or concrete you have.

Screws made for concrete have special threads and materials that resist rust and weather, so they last longer.

Following the instructions from the manufacturer or standards like the European Technical Assessment (ETA) makes your work safer.

Tip: Always double-check the screw type before you start. This small step can save you from big problems later.

If you pick the wrong screw, you risk more than just a loose fixture. Sometimes, the wrong screw can fail under pressure. This can lead to things falling, breaking, or even causing injury.

You want your project to last. The correct screw helps your work stand up to time, weather, and daily use. If you use the wrong screw or skip cleaning the hole, you might see problems like rust, broken screws, or things coming loose.

Using the wrong screw or not cleaning the hole can cause the screw to break or shear off.

Over the years, many failures have happened because people picked the wrong screw or did not follow the rules.

Non-approved screws can lead to big risks, like collapse or costly repairs.

When you choose the right screw for your cement or concrete job, you make sure everything stays strong and safe. You also avoid having to redo your work or replace broken parts. That means less stress and more time enjoying your finished project.

When you walk down the hardware aisle, you see many types of screws for concrete and cement. Each type has its own job. Picking the right one helps your project last longer and stay safe. Let’s look at the main types you’ll find.

Standard screws are the most common type you’ll see for concrete work. These usually have a blue coating or zinc plating. You use them for light to medium jobs, like hanging shelves or attaching wood to cement walls. They cost less than other types, so they work well if you want to save money and your project stays dry.

Note: Standard screws can rust if you use them outside or in wet places. You may need to check them often if you use them in a damp spot.

| Aspect | Standard Screws |

|---|---|

| Best Use | Indoor, dry areas |

| Corrosion Resistance | Low to moderate (with coating) |

| Cost | Lower |

| Durability | Good for light to medium applications |

Stainless steel screws stand out when you need strength and rust protection. You want to use this type for outdoor projects, wet basements, or anywhere moisture is a problem. Stainless steel resists rust and lasts a long time, even near the ocean or in places with chemicals.

You can use stainless steel screws for things like electrical boxes, metal brackets, or wood framing. They cost more, but you don’t have to worry about them breaking down.

Tip: If you work outside or in a wet area, always pick stainless steel screws. They keep your project safe and strong.

Self-tapping screws, like Tapcon, make your job easier. You drill a hole, then drive the screw right in. The threads cut into the concrete or cement as you go. You don’t need extra anchors or sleeves. This type works well for quick jobs, like mounting signs, light fixtures, or shelves.

Self-tapping screws save you time and hold tight in both indoor and outdoor settings. You find them in many sizes and head shapes, so you can match them to your project.

Callout: Self-tapping screws are great for masonry jobs where you want a fast, strong hold without extra parts.

Here’s a quick guide to help you choose:

| Screw Type | Best Environments/Applications |

|---|---|

| Standard Screws | Indoor, dry spaces; light to medium loads |

| Stainless Steel Screws | Outdoor, wet, or chemical-prone areas; high moisture; electrical and framing applications |

| Self-Tapping Screws | Masonry and concrete jobs; quick installs; both indoor and outdoor use |

You can also find heavy-duty anchors, drop-in anchors, and wedge bolts for bigger jobs, like machinery or structural work. Always match the screw type to your application and environment for the best results.

You want your project to last, so you need to know how to choose the right screw. Start by thinking about what you’re building and how much weight it needs to hold. Is it a heavy shelf, a handrail, or just a small hook? The load requirement tells you what kind of screw you need. If you use the wrong type, your project might not stay safe.

Here’s a simple checklist to help you with selecting the right screw:

Think about the weight your screw will support. Heavy loads need bigger, stronger screws.

Check the concrete strength. Softer concrete may need longer or thicker screws for a secure hold.

Look at the type of load. Will it pull straight out (tension), push sideways (shear), or move around (dynamic)?

Make sure the screw matches the base material. Some screws work better in solid concrete, while others fit masonry or block.

Consider the environment. If your project is outside or in a wet area, pick a screw with a rust-resistant finish and material.

Plan the spacing. Keep screws far enough from each other and from the edge of the concrete. This helps prevent cracks or weak spots.

Use the right tools. Always drill the correct hole size and clean out dust before installing the screw.

Tip: Always match the screw type to your project’s needs. For light to medium loads, concrete screws work well. For heavy-duty jobs, wedge anchors or drop-in anchors are better.

Here’s a quick table to guide your choices:

| Factor | What to Check For |

|---|---|

| Load | How much weight will the screw hold? |

| Base Material | Is it solid concrete, block, or brick? |

| Environment | Will it get wet, hot, or exposed to chemicals? |

| Anchor Size | Does the length and diameter fit your material and load? |

| Embedment Depth | Will the screw go deep enough for a strong hold? |

| Spacing & Edge Distance | Are screws far enough apart and from edges? |

| Installation | Are you using the right drill bit and cleaning the hole? |

Now let’s talk about how to choose the right screw size. This step is key for a safe and sturdy project. If you pick a size that’s too short, the screw won’t grip the concrete. If it’s too long, you might hit rebar or crack the concrete.

Follow these steps to pick a size that works:

Measure the thickness of what you’re attaching. Add at least 1 inch for embedment into the concrete. For example, if your wood is 1/2 inch thick, use a screw at least 1-1/2 inches long.

Check the diameter. Bigger diameters hold more weight. A 1/4 inch screw can handle more load than a 3/16 inch screw.

Make sure the screw goes deep enough. Most concrete screws need at least 1 inch of embedment for a strong hold. For heavy-duty jobs, you may need even more.

Avoid placing screws too close together or near the edge. Keep them at least 10 times the screw diameter apart, and 5 times the diameter from the edge.

Here’s a handy table for quick reference:

| Factor | Details / Values |

|---|---|

| Anchor Length | Material thickness + 1" embedment (min); up to material thickness + 1-3/4" (max) |

| Embedment Depth | At least 1" for most concrete screws |

| Drill Bit Size | Match to screw diameter (e.g., 3/16" bit for 1/4" screw) |

| Edge Distance | For 1/4" screw: full strength at 2.5" from edge; reduced at 1.25" |

| Spacing Between Screws | For 1/4" screw: full strength at 4" apart; reduced at 2" |

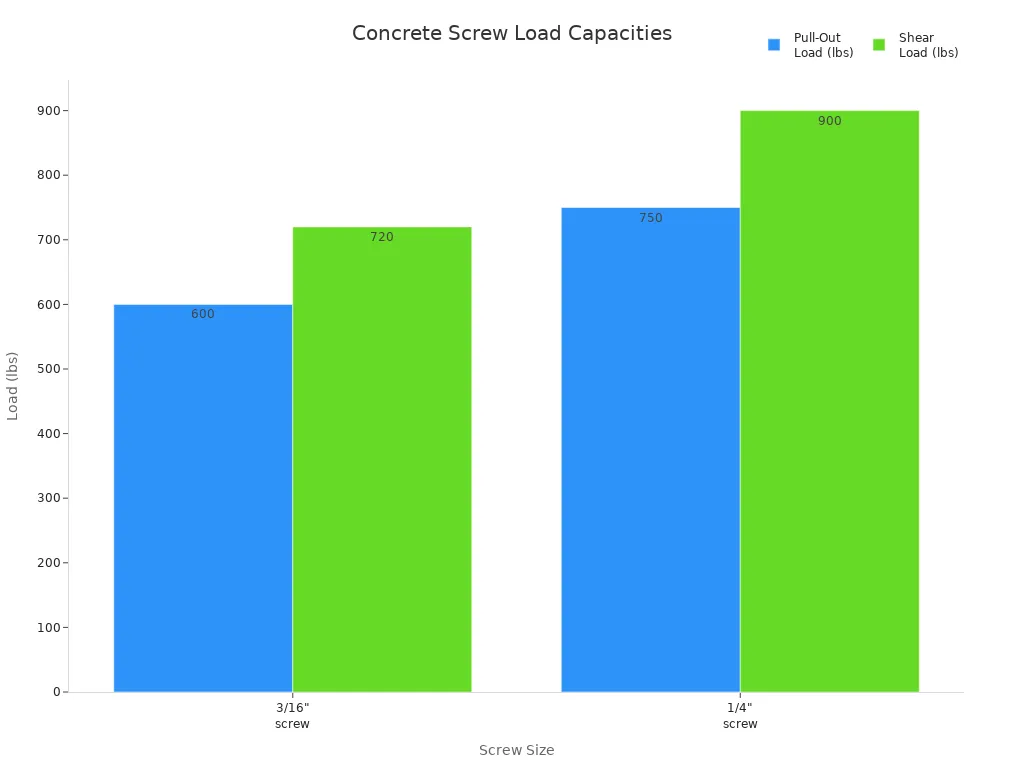

| Pull-Out Load (lbs) | 3/16" screw: 600 lbs; 1/4" screw: 750 lbs (in 2000 PSI concrete) |

| Shear Load (lbs) | 3/16" screw: 720 lbs; 1/4" screw: 900 lbs (in 2000 PSI concrete) |

| Safety Factor | Use only 25% of ultimate load as working load (4:1 safety factor) |

Note: Larger screw diameters and deeper embedment increase holding power. If you need more strength, pick a bigger screw and make sure it goes deep enough.

When you choose a screw, look at the head type. You’ll find flat, hex, and pan heads. Hex heads need a wrench or socket. Star heads (Torx) need a star bit. Pick the head that matches your tools and makes installation easy.

Thread design matters too. Special threads cut into the concrete and lock in tight. This design lets you install screws closer to edges and gives better grip, even in cracked concrete. You’ll find that screws with toughened steel threads need less force to install and hold better under stress.

Screw material and finish also play a big role. Stainless steel screws resist rust and work well outdoors or in damp places. Hot-dip galvanized screws have a thick zinc coating for extra protection. Zinc-tin alloy and RUSPERT coatings fight corrosion from chemicals and weather. Electro zinc plating gives a smooth finish for indoor jobs. Always match the screw finish and material to your environment.

Callout: If you’re working near the ocean, in a pool area, or with chemicals, use stainless steel or a high-grade coated screw for the best results.

You want the screw to fit both the thing you’re attaching and the concrete base. Make sure the screw is long enough to go through your material and deep into the concrete. Don’t use a screw that’s too short or too long. Always check the thickness of your attachment and the strength of the concrete.

Moisture, temperature swings, and chemicals can weaken screws over time. High humidity or rain can cause rust. Hot and cold weather can make screws expand and contract, which may loosen them. Chemicals can eat away at the metal. That’s why you need to choose a screw material that stands up to your environment.

Stainless steel (304 or 316) is best for harsh or wet places.

Hot-dip galvanized screws work well outside or in industrial areas.

Zinc-tin alloy and RUSPERT coatings protect against rust and chemicals.

Electro zinc plating is good for dry, indoor spaces.

Tip: Always think about where your project will live. If you’re not sure, go with a screw that has extra corrosion protection.

By following this screw buying guide, you’ll know how to choose the right screw and how to choose the right screw size for any project. Take your time, check your measurements, and pick a size that matches your needs. The right screw, size, and material will keep your project safe and strong for years.

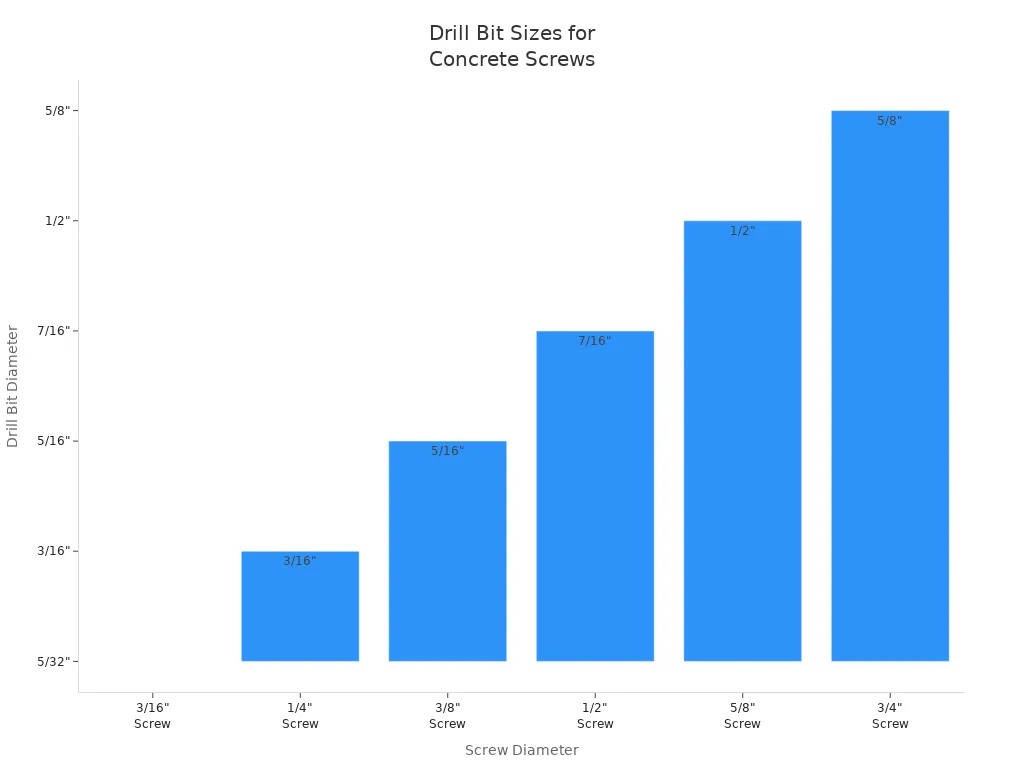

Getting the hole right is the first step to a strong hold. You want to use the correct drill bit size for your concrete screw. If the hole is too big, the screw won’t grip. If it’s too small, you might break the screw or struggle to drive it in. Always check the packaging for the recommended drill bit size. Here’s a quick table to help you match screw diameter to drill bit size:

| Concrete Screw Diameter (Tapcon®) | Recommended Drill Bit Diameter |

|---|---|

| 3/16" | 5/32" |

| 1/4" | 3/16" |

| 3/8" | 5/16" |

| 1/2" | 7/16" |

| 5/8" | 1/2" |

| 3/4" | 5/8" |

You should use a carbide-tipped bit and a hammer drill set to hammer and rotation mode. This combo makes drilling into concrete much easier. Drill to the right depth—at least as deep as the screw will go. Clean out the dust before you install the screw. Dust in the hole can stop the screw from holding tight.

Tip: Always double-check your drill bit size before you start. A small mistake here can lead to a weak hold.

You want your screw to last, not snap or strip. Over-tightening is a common mistake. Many people think tighter is better, but that’s not true for concrete screws. If you use too much force, you can strip the threads, snap the screw head, or even damage the hole. This makes the screw weaker and harder to remove later.

Over-tightening can pull the screw head below the surface and warp the threads.

Too much torque can cause brittle screws to break, especially in high-strength steel.

Always use a torque control drill or a torque wrench to avoid going too far.

Note: Tighten the screw until it feels snug and secure, but stop before you feel strong resistance.

If you’re working outdoors or in harsh weather, pick screws with rust-resistant coatings. Stainless steel or hot-dip galvanized screws work best for wet or salty places. Always check that your screw matches the concrete and the environment.

By following these tips, you’ll get a strong, safe hold every time.

Everyone makes mistakes, but you can avoid the most common ones when picking and installing concrete screws. Let’s look at what usually goes wrong and how you can fix it fast.

Choosing the wrong size is a top mistake. If your screw is too short, it won’t grip the concrete. If it’s too long, you might hit rebar or crack the surface. Sometimes, people use a screw that’s too thin, and it can’t hold the weight. Using the wrong size can also strip the threads or make the anchor spin in the hole.

Overdriving the screw after it touches the surface strips the threads.

Drilling a hole that’s too shallow or too wide lowers holding strength.

If the anchor spins freely, it means the concrete threads are stripped.

Tip: Always check the manufacturer’s guide for the right hole depth and diameter. If you make a mistake, drill a new hole instead of reusing the old one.

You need to know how much weight your screw will hold. Ignoring the load can lead to loose fixtures or even failure. Using a wood screw in concrete or picking a screw that’s not strong enough for the job can cause splitting, stripping, or loosening over time.

Not matching the screw to the load causes it to fail.

Over-tightening or under-tightening reduces holding power.

Fastener compatibility with your material is key.

Callout: Always calculate the load before you pick your screw. Make sure it’s the right type and size for your project.

If you skip checking for corrosion resistance, your project may not last. Using regular screws in wet or outdoor areas leads to rust and weakens the connection. Rusty screws can break, causing costly repairs.

Non-corrosion-resistant screws fail in damp or chemical areas.

Corrosion weakens the structure and makes the connection loose.

High-quality screws made from stainless steel or with special coatings last longer.

Note: For outdoor or humid spots, always use stainless steel or coated screws. This keeps your project strong and safe.

Quick Fixes for Common Mistakes:

Drill pilot holes to the correct depth and diameter.

Remove dust from holes before installing the screw.

Use the right torque—don’t over-tighten.

Pick corrosion-resistant screws like galvanized or stainless steel for tough environments.

Never reuse a screw in the same hole.

You want your project to be strong and safe for a long time. Before you pick a fastener, always check the load, size, material, and where you will use it. This table can help you remember what to look for:

| What to Check | Why It Matters |

|---|---|

| Load | Stops things from coming loose |

| Size | Makes sure the screw holds tight |

| Material | Helps stop rust and weak spots |

| Environment | Keeps your project safe outside |

Use the buying guide each time you start a project.

Pick good fasteners and use the right tools.

Work safely and feel proud of your finished job!

You need to match the drill bit size to your screw. For a 1/4" concrete screw, use a 3/16" bit. Always check the package for the right size. Using the wrong bit can make the screw loose or hard to install.

No, you should not reuse a concrete screw in the same hole. The threads in the concrete get damaged after the first use. If you need to reinstall, drill a new hole nearby for a strong hold.

You do not need anchors with most concrete screws. These screws cut their own threads into the concrete. Just pre-drill the hole, clean out the dust, and drive the screw in. Anchors are only needed for other types of fasteners.

Pick screws with rust-resistant coatings or made from stainless steel. These hold up better in wet or humid places. If you use regular screws outside, they can rust and weaken. Always check the label for corrosion resistance.