- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

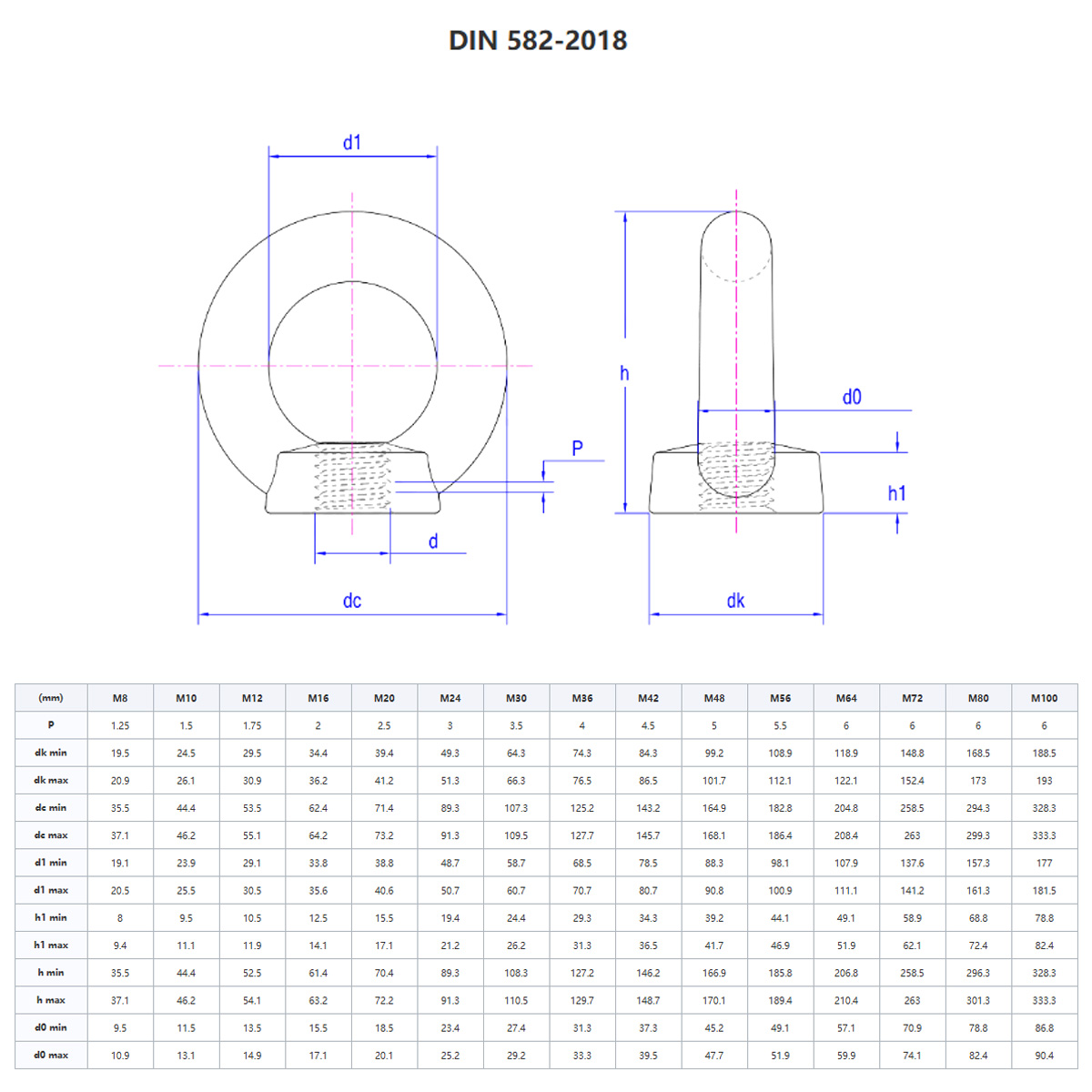

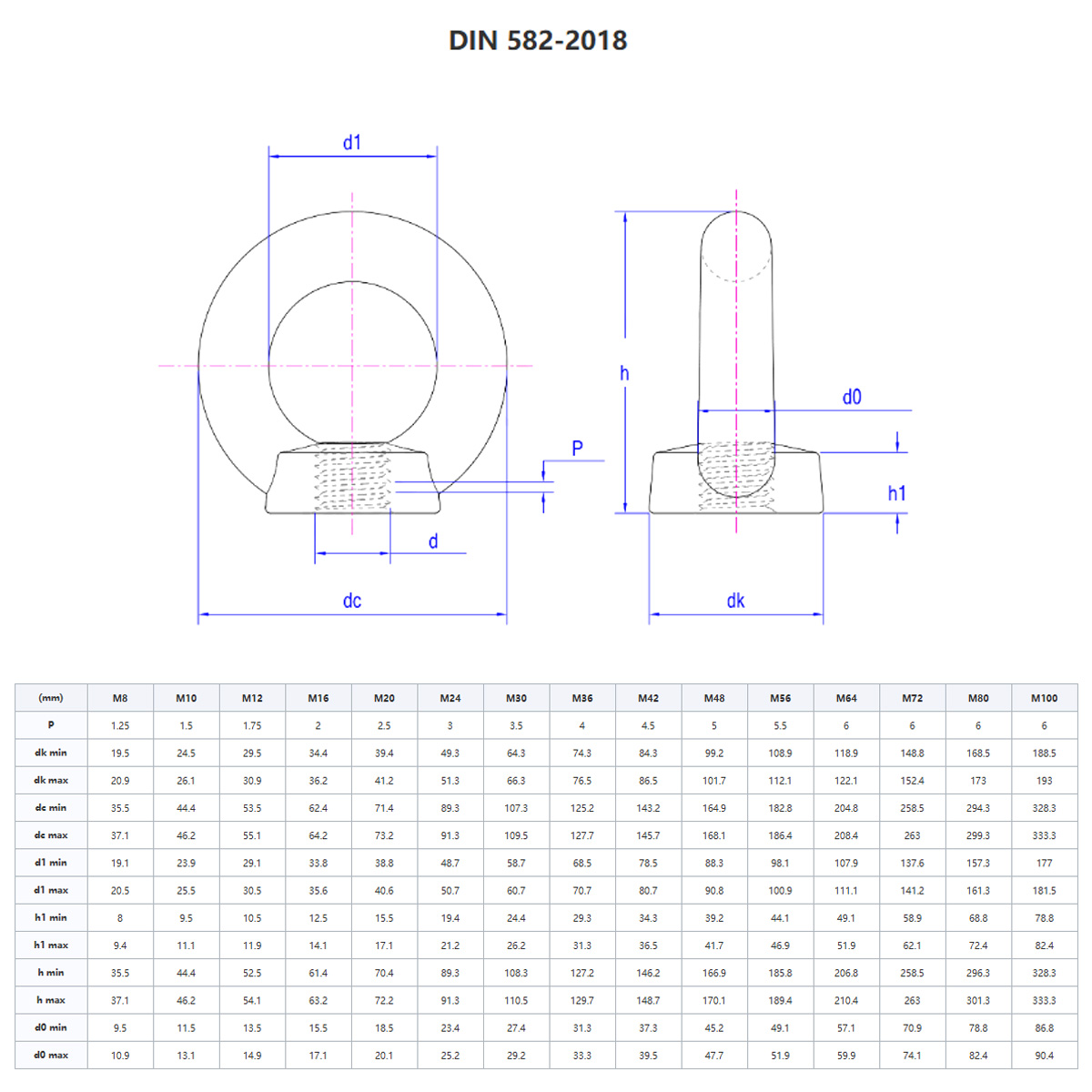

DIN582

HNF

HINA2025021202

The eye nut is a fastener with a ring structure and internal threads. It is usually made of high-strength metal materials such as alloy steel, stainless steel, etc. It has a standard thread on the inside, which can be used with bolts or studs with external threads to achieve connection and tightening by tightening. It has a ring structure on the top or side, and this ring can be easily passed through ropes, chains or other lifting tools for lifting, hanging or fixing objects.

Strong bearing capacity: It is generally made of high-strength materials, and has high strength and hardness after forging, quenching, tempering and other processes. It can withstand large tension and weight and can meet the lifting needs in different scenarios.

Reliable connection: It is used in conjunction with bolts or studs to form a stable mechanical connection through threaded connection. During the lifting process, it can ensure that the connection parts will not loosen or fall off easily, ensuring the safety of the lifting operation.

Convenient installation: The structure is relatively simple. When installing, you only need to screw the eye nut onto the corresponding bolt or stud. The operation is convenient and quick, and does not require complex tools and techniques, which can improve the installation efficiency.

Flexible use: The ring structure design allows it to be used with various lifting tools, such as hooks, slings, chains, etc., and is suitable for lifting operations at different angles and methods. The direction and position of the lifting ring can also be adjusted as needed.

Good corrosion resistance: Some lifting ring nuts are made of corrosion-resistant materials such as stainless steel, which can maintain good performance in corrosive environments such as moisture, acid and alkali, and are not easy to rust and damage, extending the service life.

Manufacturing: In mechanical manufacturing, it is used to connect and fix components in mechanical equipment, such as the lifting and installation of large molds, motors, reducers, etc.; in automobile manufacturing, it can be used for the handling and assembly of parts such as engines and gearboxes.

Construction industry: It is often used to lift and fix building materials and equipment, such as the lifting of steel beams and steel columns of steel structures, the installation of building curtain walls, and the installation and positioning of large air-conditioning units, elevators and other equipment.

Transportation: In the manufacturing and maintenance of vehicles, ships and other means of transportation, it is used to lift large components such as engines and chassis; in cargo transportation, it can be used to fix cargo to prevent it from moving during transportation.

Aerospace: In the manufacturing and maintenance of aerospace vehicles such as aircraft and rockets, it is used to hoist and fix various parts, such as engines, wings, tail fins, etc., which require extremely high product quality and reliability.

Energy industry: In the manufacturing and installation of new energy equipment such as wind power and solar energy, it is used to hoist the towers and blades of wind turbines, the brackets of solar panels, etc.; in the petrochemical industry, it is used to hoist various large storage tanks, reactors and other equipment.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

1. What are the common applications of nuts?

Nuts are used in a wide range of applications, including:

Automotive: Securing parts in engines, chassis, and body assemblies.

Construction: Fastening structural components in buildings and bridges.

Mechanical Engineering: Connecting machine parts and components.

Electrical: Used in electrical panels and equipment to secure components.

2. How do I choose the right nut for my application?

When selecting a nut, consider the following:

Material: Choose based on the environmental conditions (e.g., stainless steel for corrosion resistance).

Size: Ensure the nut matches the bolt or screw it will be used with.

Type: Select the appropriate type (e.g., lock nuts for vibration resistance).

Finish: Consider the required surface treatment (e.g., galvanized for outdoor use).

The eye nut is a fastener with a ring structure and internal threads. It is usually made of high-strength metal materials such as alloy steel, stainless steel, etc. It has a standard thread on the inside, which can be used with bolts or studs with external threads to achieve connection and tightening by tightening. It has a ring structure on the top or side, and this ring can be easily passed through ropes, chains or other lifting tools for lifting, hanging or fixing objects.

Strong bearing capacity: It is generally made of high-strength materials, and has high strength and hardness after forging, quenching, tempering and other processes. It can withstand large tension and weight and can meet the lifting needs in different scenarios.

Reliable connection: It is used in conjunction with bolts or studs to form a stable mechanical connection through threaded connection. During the lifting process, it can ensure that the connection parts will not loosen or fall off easily, ensuring the safety of the lifting operation.

Convenient installation: The structure is relatively simple. When installing, you only need to screw the eye nut onto the corresponding bolt or stud. The operation is convenient and quick, and does not require complex tools and techniques, which can improve the installation efficiency.

Flexible use: The ring structure design allows it to be used with various lifting tools, such as hooks, slings, chains, etc., and is suitable for lifting operations at different angles and methods. The direction and position of the lifting ring can also be adjusted as needed.

Good corrosion resistance: Some lifting ring nuts are made of corrosion-resistant materials such as stainless steel, which can maintain good performance in corrosive environments such as moisture, acid and alkali, and are not easy to rust and damage, extending the service life.

Manufacturing: In mechanical manufacturing, it is used to connect and fix components in mechanical equipment, such as the lifting and installation of large molds, motors, reducers, etc.; in automobile manufacturing, it can be used for the handling and assembly of parts such as engines and gearboxes.

Construction industry: It is often used to lift and fix building materials and equipment, such as the lifting of steel beams and steel columns of steel structures, the installation of building curtain walls, and the installation and positioning of large air-conditioning units, elevators and other equipment.

Transportation: In the manufacturing and maintenance of vehicles, ships and other means of transportation, it is used to lift large components such as engines and chassis; in cargo transportation, it can be used to fix cargo to prevent it from moving during transportation.

Aerospace: In the manufacturing and maintenance of aerospace vehicles such as aircraft and rockets, it is used to hoist and fix various parts, such as engines, wings, tail fins, etc., which require extremely high product quality and reliability.

Energy industry: In the manufacturing and installation of new energy equipment such as wind power and solar energy, it is used to hoist the towers and blades of wind turbines, the brackets of solar panels, etc.; in the petrochemical industry, it is used to hoist various large storage tanks, reactors and other equipment.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

1. What are the common applications of nuts?

Nuts are used in a wide range of applications, including:

Automotive: Securing parts in engines, chassis, and body assemblies.

Construction: Fastening structural components in buildings and bridges.

Mechanical Engineering: Connecting machine parts and components.

Electrical: Used in electrical panels and equipment to secure components.

2. How do I choose the right nut for my application?

When selecting a nut, consider the following:

Material: Choose based on the environmental conditions (e.g., stainless steel for corrosion resistance).

Size: Ensure the nut matches the bolt or screw it will be used with.

Type: Select the appropriate type (e.g., lock nuts for vibration resistance).

Finish: Consider the required surface treatment (e.g., galvanized for outdoor use).