- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

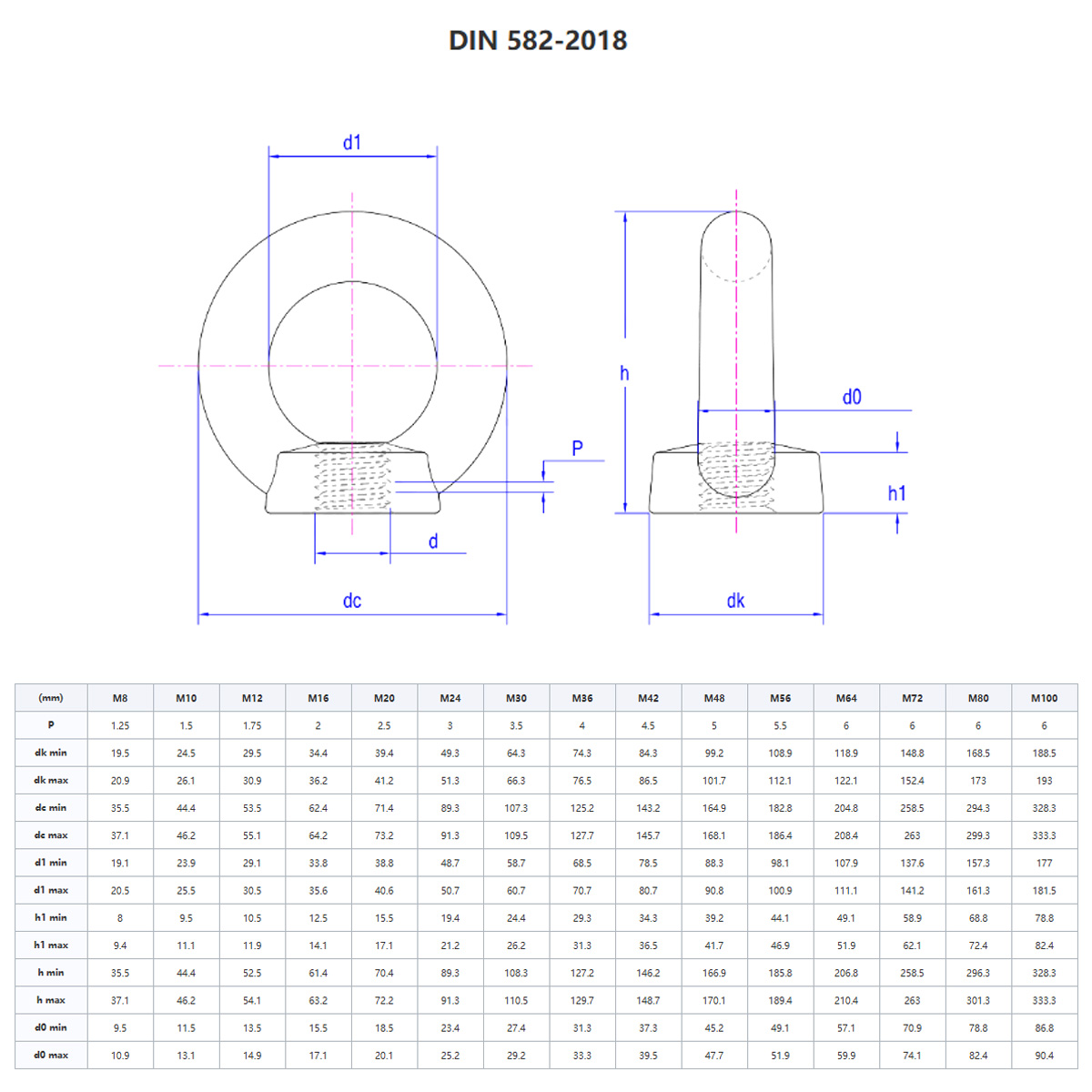

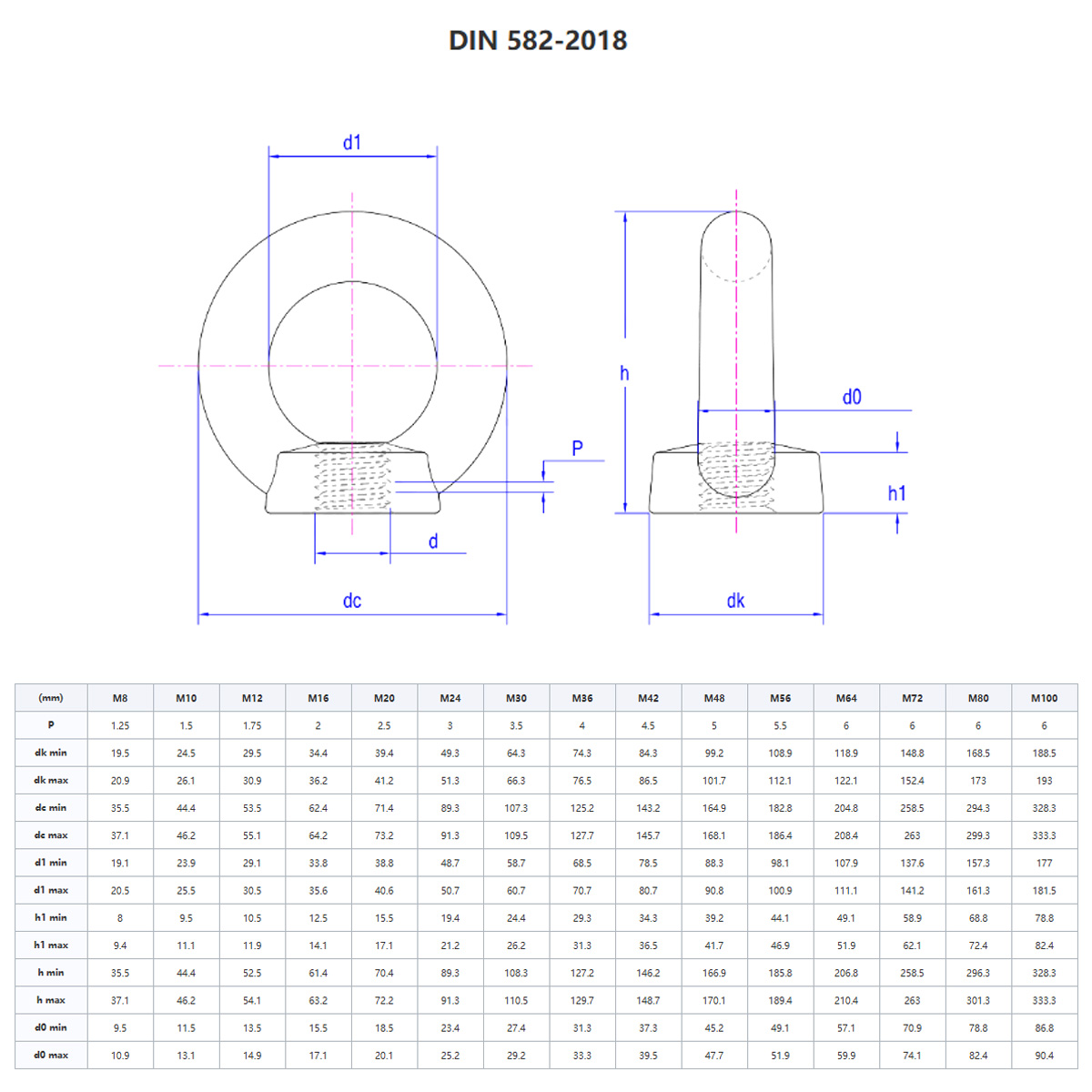

DIN582

HNF

HINA2025021203

Carbon steel eye nuts are fastening components featuring internal threads and an eye - shaped structure. They are primarily crafted from medium - carbon or high - carbon steel through processes such as forging and machining. The interior has standard threads that can be paired with corresponding bolts or studs for mechanical connection. At the top, there is an eye - shaped loop structure used to connect lifting equipment like hooks and slings, enabling the lifting, suspension, or handling of objects.

High strength and good toughness: Carbon steel itself has high strength and relatively good toughness. After appropriate heat treatment processes, carbon steel eye nuts are less likely to break when subjected to high tensile forces. Meanwhile, they also have certain anti - deformation capabilities when affected by impact loads, ensuring the safety and reliability of the lifting process.

Cost - effective: Compared with some eye nuts made of special alloys or precious metals, carbon steel is relatively low - priced. It can effectively reduce production costs while ensuring performance, making it highly cost - effective and suitable for scenarios where a large number of eye nuts are required.

Good machinability: Carbon steel has excellent workability and is easy to forge, cut, drill, and perform other machining operations. It can be conveniently manufactured into eye nuts of various specifications and precision requirements to meet the needs of different users.

Strong adaptability to surface treatment: The surface of carbon steel can undergo various treatments, such as galvanizing, nickel - plating, blackening, etc. These surface treatments can effectively improve the corrosion resistance and wear resistance of eye nuts, enabling them to be used in different working environments.

Industrial equipment installation: In factories, it is often used in the installation and commissioning of large - scale mechanical equipment. For example, during the lifting of large motors, compressors, reducers, and other equipment, carbon steel eye nuts are paired with corresponding bolts to lift the equipment steadily and install it in the designated position.

Construction projects: In the construction field, it can be used for lifting building components, such as precast beams, columns, and large - scale steel structures. It is also used for the connection and lifting of components of tower cranes and other construction equipment, ensuring safety and efficiency during the construction process.

Logistics and warehousing: In the logistics industry, it is used for the lifting and handling of goods. For example, lifting large - sized goods from transport vehicles and placing them on warehouse shelves, or during the loading and unloading of goods, connecting the lifting gear and the goods through eye nuts to achieve rapid loading and unloading of goods.

Mechanical maintenance and repair: During the maintenance and repair of mechanical equipment, carbon steel eye nuts can be used to disassemble and install the components of mechanical equipment, facilitating the inspection and maintenance work of maintenance personnel.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

1. What are lock nuts used for?

Lock nuts are designed to prevent loosening due to vibration. They are commonly used in applications where high reliability and resistance to movement are required, such as in automotive, aerospace, and industrial machinery.

2. What is the difference between a nut and a bolt?

A nut is a fastener with a threaded hole that is designed to be used with a bolt or screw. A bolt, on the other hand, is a fastener with an external thread that is used to secure two or more parts together when paired with a nut.

Carbon steel eye nuts are fastening components featuring internal threads and an eye - shaped structure. They are primarily crafted from medium - carbon or high - carbon steel through processes such as forging and machining. The interior has standard threads that can be paired with corresponding bolts or studs for mechanical connection. At the top, there is an eye - shaped loop structure used to connect lifting equipment like hooks and slings, enabling the lifting, suspension, or handling of objects.

High strength and good toughness: Carbon steel itself has high strength and relatively good toughness. After appropriate heat treatment processes, carbon steel eye nuts are less likely to break when subjected to high tensile forces. Meanwhile, they also have certain anti - deformation capabilities when affected by impact loads, ensuring the safety and reliability of the lifting process.

Cost - effective: Compared with some eye nuts made of special alloys or precious metals, carbon steel is relatively low - priced. It can effectively reduce production costs while ensuring performance, making it highly cost - effective and suitable for scenarios where a large number of eye nuts are required.

Good machinability: Carbon steel has excellent workability and is easy to forge, cut, drill, and perform other machining operations. It can be conveniently manufactured into eye nuts of various specifications and precision requirements to meet the needs of different users.

Strong adaptability to surface treatment: The surface of carbon steel can undergo various treatments, such as galvanizing, nickel - plating, blackening, etc. These surface treatments can effectively improve the corrosion resistance and wear resistance of eye nuts, enabling them to be used in different working environments.

Industrial equipment installation: In factories, it is often used in the installation and commissioning of large - scale mechanical equipment. For example, during the lifting of large motors, compressors, reducers, and other equipment, carbon steel eye nuts are paired with corresponding bolts to lift the equipment steadily and install it in the designated position.

Construction projects: In the construction field, it can be used for lifting building components, such as precast beams, columns, and large - scale steel structures. It is also used for the connection and lifting of components of tower cranes and other construction equipment, ensuring safety and efficiency during the construction process.

Logistics and warehousing: In the logistics industry, it is used for the lifting and handling of goods. For example, lifting large - sized goods from transport vehicles and placing them on warehouse shelves, or during the loading and unloading of goods, connecting the lifting gear and the goods through eye nuts to achieve rapid loading and unloading of goods.

Mechanical maintenance and repair: During the maintenance and repair of mechanical equipment, carbon steel eye nuts can be used to disassemble and install the components of mechanical equipment, facilitating the inspection and maintenance work of maintenance personnel.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

1. What are lock nuts used for?

Lock nuts are designed to prevent loosening due to vibration. They are commonly used in applications where high reliability and resistance to movement are required, such as in automotive, aerospace, and industrial machinery.

2. What is the difference between a nut and a bolt?

A nut is a fastener with a threaded hole that is designed to be used with a bolt or screw. A bolt, on the other hand, is a fastener with an external thread that is used to secure two or more parts together when paired with a nut.