2025-06-08 Haina Invites You to SNEC PV POWER+ EXPO Exhibition !The highly anticipated annual event in the global photovoltaic (PV) industry, the 2025 SNEC PV POWER+ EXPO Exhibition (the 18th International Photovoltaic Power Generation and Smart Energy Conference & Exhibition), is about to kick off! Zhejiang H

Read More

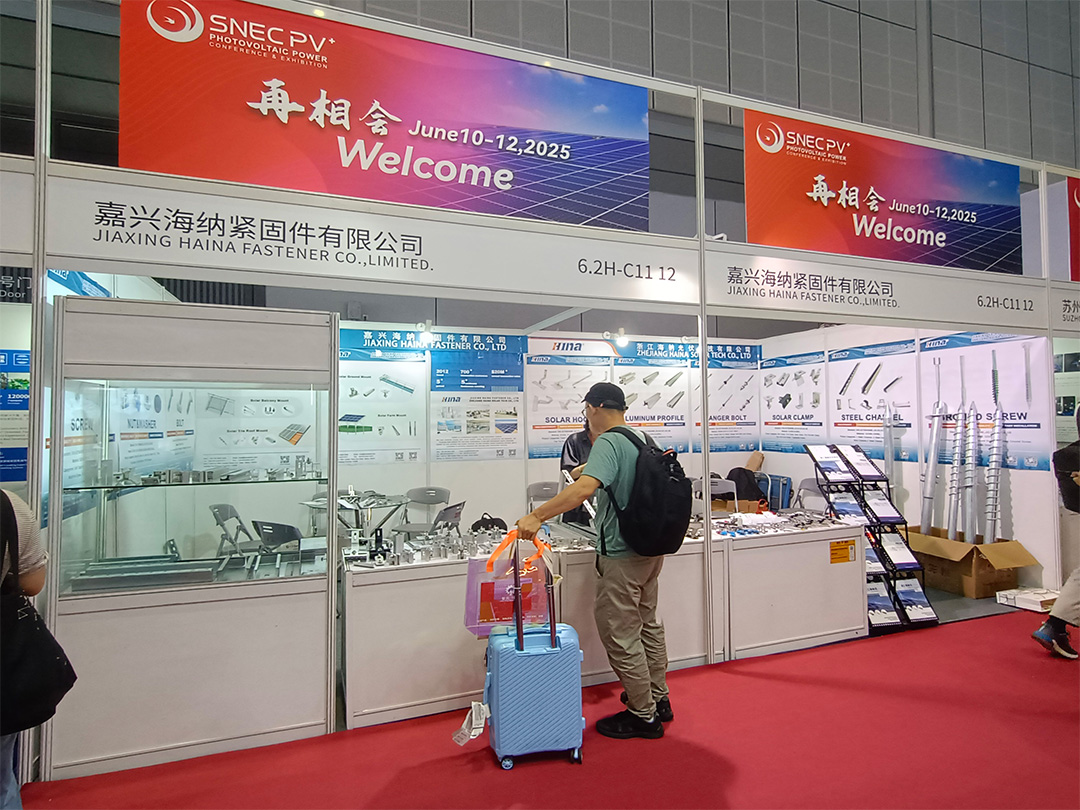

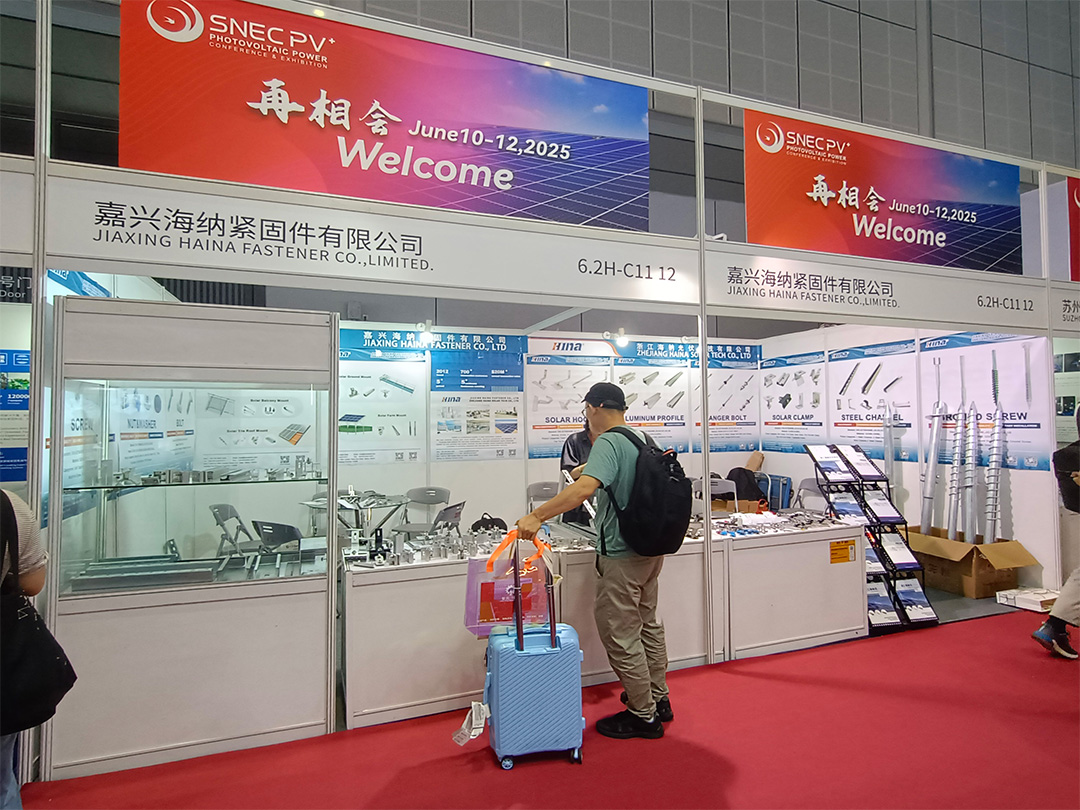

2024-05-17 Shanghai - From June 13 to 15, 2024, the annual global photovoltaic industry event - SNEC 17th (2024) International Solar Photovoltaic and Smart Energy (Shanghai) Conference and Exhibition was grandly held at the National Exhibition and Convention Center (Shanghai). Haina brought its latest develope

Read More

2021-12-09 Haina Fasteners participated in the 15th photovoltaic exhibition in 2021. We met many new customers, and we provided these customers with professional photovoltaic fasteners.Like stud bolts, hexagon bolts, carriage bolts, hexagon socket bolts, T-bolts, flange nuts, hexagon nuts, washers, self-tappin

Read More

2021-12-09 Haina Fasteners registered a new trademark HINA in March 2021It will help Haina to open up the international market and also make Haina popularity to the world

Read More