- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

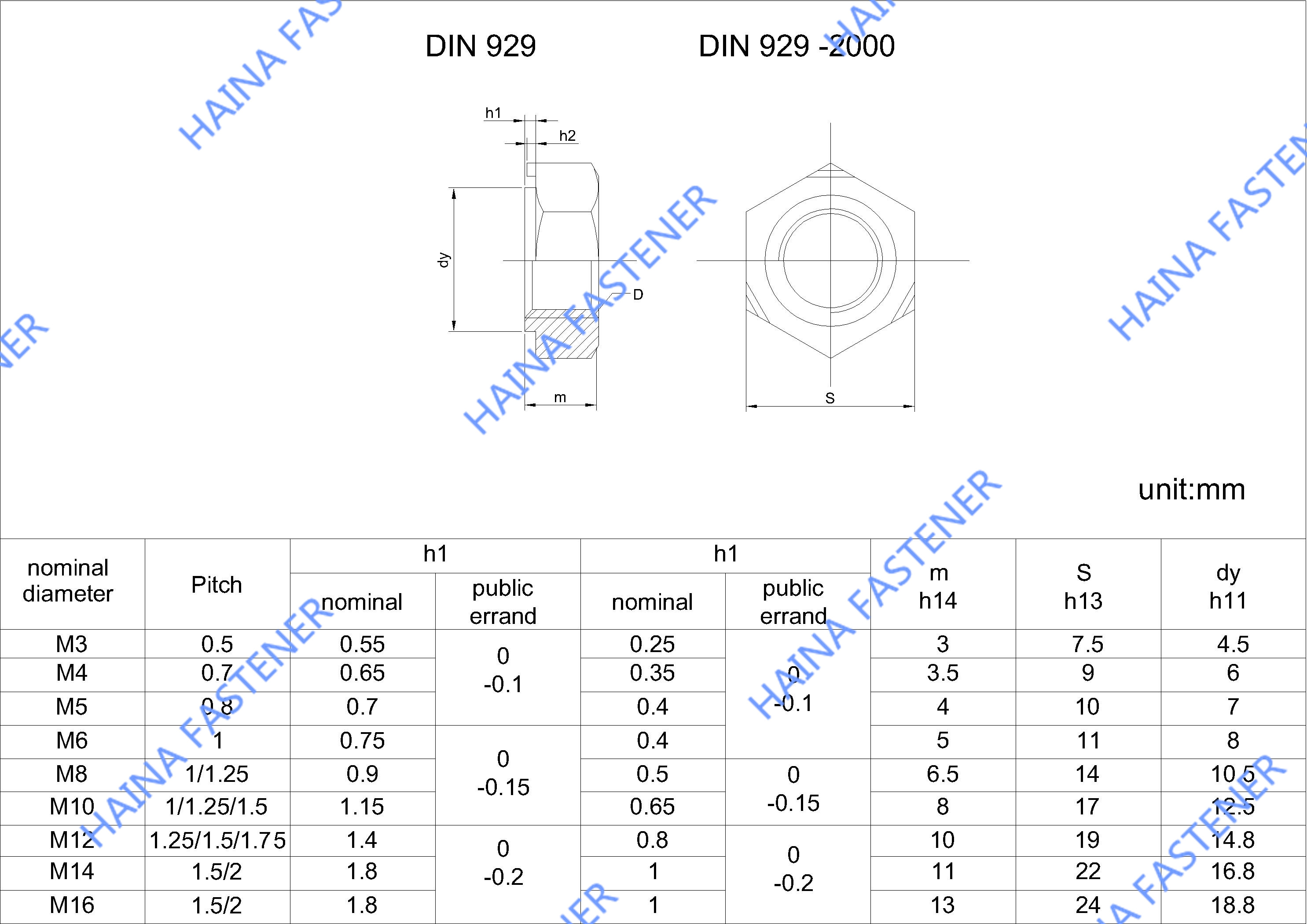

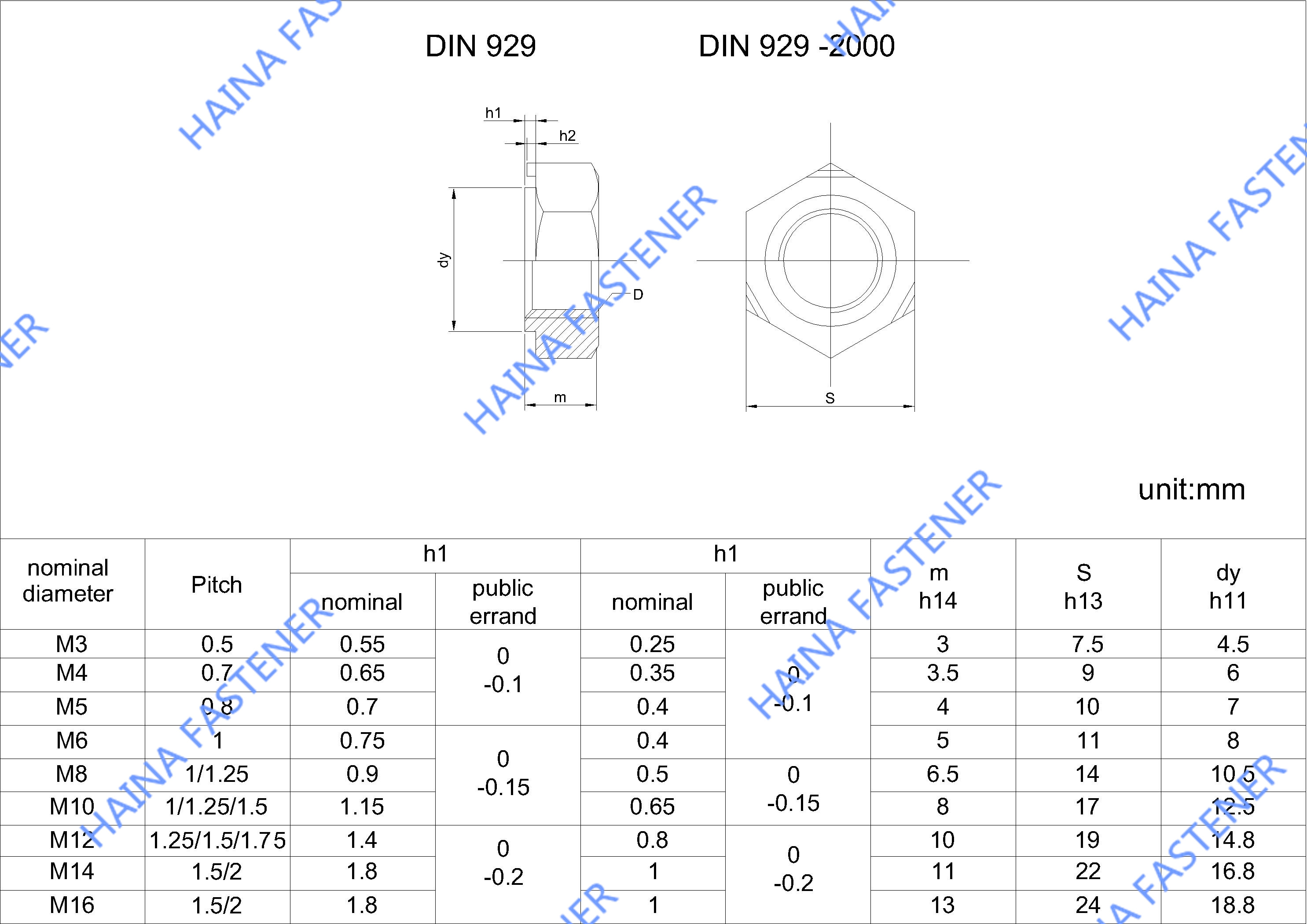

DIN929

HIHA

2021123001

Stainless steel welding nuts refer to nuts made of stainless steel and specially used to connect with other metal parts through welding process. It usually has a standard nut shape, such as hexagonal, with internal threads, and a structure designed on its surface or edge to facilitate welding. It is firmly attached to the workpiece through welding to provide a connection point for the bolt to achieve a fastening connection between parts.

Excellent corrosion resistance: Stainless steel contains alloy elements such as chromium and nickel, which can form a dense passivation film on the surface, giving it excellent corrosion resistance. It can resist the erosion of chemical substances such as acids, alkalis, salts, and harsh environments such as humidity and ocean. It is particularly suitable for equipment and structures in outdoor or corrosive media, and can effectively extend its service life.

High strength and good toughness: Stainless steel has high strength and hardness, as well as good toughness, which makes stainless steel welding nuts less likely to deform or break when subjected to large tension, pressure and shear force, and can ensure the reliability and stability of the connection, and maintain good performance even under complex working conditions such as vibration and impact.

Good welding performance: Stainless steel has good weldability. During the welding process, it can form a strong metallurgical bond with the connected metal parts. The welded joint has high strength and is not prone to welding defects such as cracks and pores, which ensures the welding quality and the firmness of the connection.

Good aesthetics: Stainless steel has a metallic luster, a smooth surface, and a neat and beautiful appearance. In some equipment and products that require appearance, the use of stainless steel welding nuts will not affect the overall aesthetics, but will enhance the quality of the product.

Hygiene and environmental protection: Stainless steel is non-toxic, odorless, does not release harmful substances, meets hygiene standards, and is widely used in industries with high hygiene requirements such as food and medicine. It also has good environmental protection performance and can be recycled and reused.

Food and beverage industry: In food processing equipment, beverage filling production lines and other equipment, it is used to connect and fix various parts, such as conveyor belt brackets, agitators, tanks, etc. Its corrosion resistance and hygiene can ensure that the equipment will not rust and pollute in an environment where it is in long-term contact with food and beverages, ensuring the quality and safety of food and beverages.

Medical equipment: In the manufacture of pharmaceutical machinery and medical equipment, such as tablet presses, capsule filling machines, and medical testing equipment on pharmaceutical production lines, stainless steel welding nuts are used to fix and connect various components to meet the equipment's requirements for corrosion resistance, hygiene, and stability, ensuring that the equipment operates normally in a strict sanitary environment.

Marine engineering: In the field of marine engineering such as shipbuilding and offshore oil platforms, due to the high salinity and humid marine environment, the corrosion resistance of components is extremely high. Stainless steel welding nuts can be used to connect the decks, cabin structures, and steel structures of offshore platforms of ships, which can effectively resist the corrosion of seawater and ensure the safety and reliability of marine engineering facilities.

Chemical equipment: In chemical production, various reactors, storage tanks, pipelines and other equipment are often exposed to corrosive chemicals such as acids, alkalis, and salts. With its excellent corrosion resistance, stainless steel welding nuts can be used for the assembly and connection of these chemical equipment to ensure long-term and stable operation of the equipment in harsh chemical environments.

Architectural decoration: In the field of architectural decoration, it is used to connect and fix stainless steel railings, handrails, curtain wall keels and other decorative parts. It not only provides a firm connection, but also matches the appearance of stainless steel decorative materials, thus improving the overall aesthetics and quality of architectural decoration.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

What are the advantages of welding nuts?

High Strength: Provides a robust connection that can withstand significant loads.

Permanent Fixing: Once welded, the nut is securely attached and unlikely to loosen.

Space-Saving: No additional space is required for the nut head, making it suitable for tight spaces.

Versatility: Available in various sizes and shapes to meet different needs.

How are welding nuts installed?

Welding nuts are installed using a welding process, typically spot welding or projection welding. The nut is placed on the surface to be fastened, and a weld is created to bond the nut securely to the material.

Stainless steel welding nuts refer to nuts made of stainless steel and specially used to connect with other metal parts through welding process. It usually has a standard nut shape, such as hexagonal, with internal threads, and a structure designed on its surface or edge to facilitate welding. It is firmly attached to the workpiece through welding to provide a connection point for the bolt to achieve a fastening connection between parts.

Excellent corrosion resistance: Stainless steel contains alloy elements such as chromium and nickel, which can form a dense passivation film on the surface, giving it excellent corrosion resistance. It can resist the erosion of chemical substances such as acids, alkalis, salts, and harsh environments such as humidity and ocean. It is particularly suitable for equipment and structures in outdoor or corrosive media, and can effectively extend its service life.

High strength and good toughness: Stainless steel has high strength and hardness, as well as good toughness, which makes stainless steel welding nuts less likely to deform or break when subjected to large tension, pressure and shear force, and can ensure the reliability and stability of the connection, and maintain good performance even under complex working conditions such as vibration and impact.

Good welding performance: Stainless steel has good weldability. During the welding process, it can form a strong metallurgical bond with the connected metal parts. The welded joint has high strength and is not prone to welding defects such as cracks and pores, which ensures the welding quality and the firmness of the connection.

Good aesthetics: Stainless steel has a metallic luster, a smooth surface, and a neat and beautiful appearance. In some equipment and products that require appearance, the use of stainless steel welding nuts will not affect the overall aesthetics, but will enhance the quality of the product.

Hygiene and environmental protection: Stainless steel is non-toxic, odorless, does not release harmful substances, meets hygiene standards, and is widely used in industries with high hygiene requirements such as food and medicine. It also has good environmental protection performance and can be recycled and reused.

Food and beverage industry: In food processing equipment, beverage filling production lines and other equipment, it is used to connect and fix various parts, such as conveyor belt brackets, agitators, tanks, etc. Its corrosion resistance and hygiene can ensure that the equipment will not rust and pollute in an environment where it is in long-term contact with food and beverages, ensuring the quality and safety of food and beverages.

Medical equipment: In the manufacture of pharmaceutical machinery and medical equipment, such as tablet presses, capsule filling machines, and medical testing equipment on pharmaceutical production lines, stainless steel welding nuts are used to fix and connect various components to meet the equipment's requirements for corrosion resistance, hygiene, and stability, ensuring that the equipment operates normally in a strict sanitary environment.

Marine engineering: In the field of marine engineering such as shipbuilding and offshore oil platforms, due to the high salinity and humid marine environment, the corrosion resistance of components is extremely high. Stainless steel welding nuts can be used to connect the decks, cabin structures, and steel structures of offshore platforms of ships, which can effectively resist the corrosion of seawater and ensure the safety and reliability of marine engineering facilities.

Chemical equipment: In chemical production, various reactors, storage tanks, pipelines and other equipment are often exposed to corrosive chemicals such as acids, alkalis, and salts. With its excellent corrosion resistance, stainless steel welding nuts can be used for the assembly and connection of these chemical equipment to ensure long-term and stable operation of the equipment in harsh chemical environments.

Architectural decoration: In the field of architectural decoration, it is used to connect and fix stainless steel railings, handrails, curtain wall keels and other decorative parts. It not only provides a firm connection, but also matches the appearance of stainless steel decorative materials, thus improving the overall aesthetics and quality of architectural decoration.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

What are the advantages of welding nuts?

High Strength: Provides a robust connection that can withstand significant loads.

Permanent Fixing: Once welded, the nut is securely attached and unlikely to loosen.

Space-Saving: No additional space is required for the nut head, making it suitable for tight spaces.

Versatility: Available in various sizes and shapes to meet different needs.

How are welding nuts installed?

Welding nuts are installed using a welding process, typically spot welding or projection welding. The nut is placed on the surface to be fastened, and a weld is created to bond the nut securely to the material.