- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2025-06-14 Origin: Site

If you need to attach things like shelves or signs to concrete or brick, sleeve anchors are a great choice. These special fasteners expand to hold tightly in hard materials. They work well for small or big jobs, whether at home or work.

Installing them the right way is very important. When done correctly, sleeve anchors stay strong and secure for a long time. Want to know how to use them properly? Let’s get started!

Sleeve anchors are tools used to attach things to hard surfaces like concrete, brick, or stone. They have a bolt with a metal sleeve around it. When you tighten the bolt, the sleeve gets bigger. This makes it hold tightly in the hole and keeps it strong.

Here’s how they work:

Tightening the bolt makes the sleeve expand.

The sleeve pushes against the hole walls to stay secure.

Crimped sleeves are great for strong, lasting holds in concrete. They have a steel sleeve with threads inside, making them very strong. Tests show crimped sleeves work even better in concrete with steel fibers. The fibers add extra strength.

Aspect | Description |

|---|---|

Methodology | Sleeve thickness depends on damage from stiffness. |

Testing | Pull-out tests check bolt strength with metal sleeves. |

Findings | Formulas help calculate sleeve thickness and stiffness. |

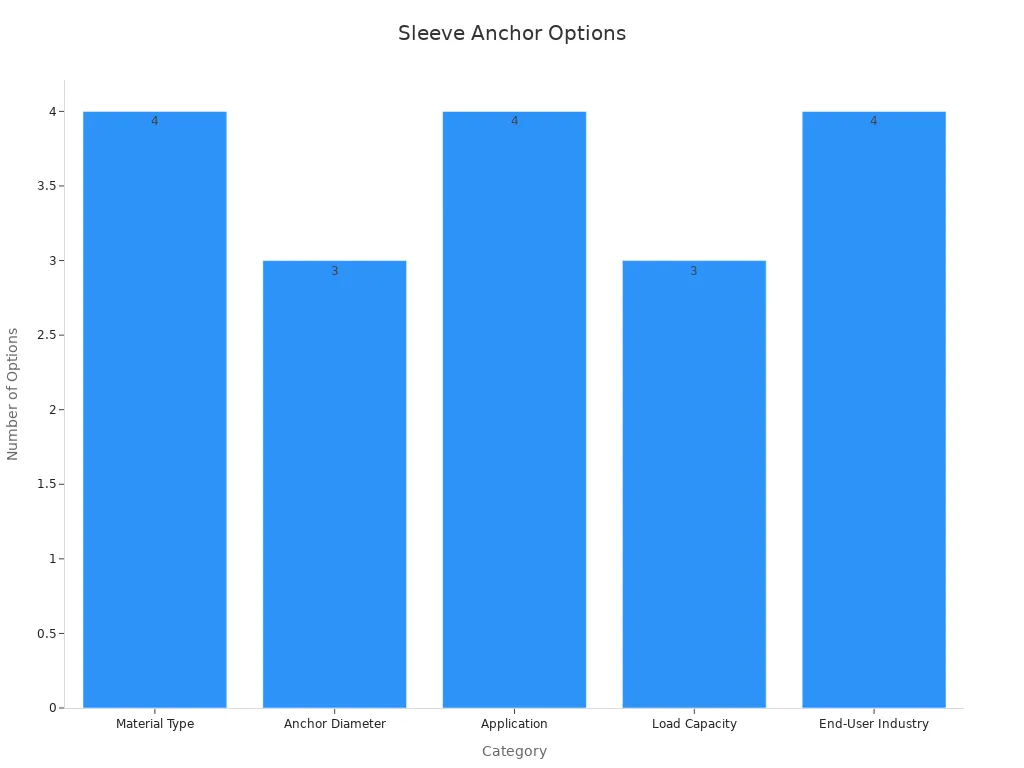

There are different types of sleeve anchors for various jobs. Picking the right one depends on the material, weight it holds, and where it’s used.

Category | Types/Details |

|---|---|

Material Type | Stainless Steel, Carbon Steel, Aluminum, Bronze |

Anchor Diameter | Less than 5/16 inch, 5/16 - 1/2 inch, Over 1/2 inch |

Application | Construction, Manufacturing, Automotive, Marine |

Load Capacity | Light Duty, Medium Duty, Heavy Duty |

End-User Industry | Residential, Commercial, Industrial, Infrastructure |

For example, stainless steel anchors don’t rust, so they’re good outdoors. Heavy-duty anchors hold big loads, while light-duty ones are for smaller items.

Sleeve anchors are made from strong materials like stainless steel, carbon steel, and aluminum. These materials make them tough and long-lasting. But they don’t work on all surfaces. For example, they can harm wood because the sleeve expands too much.

Remember:

Sleeve anchors are best for concrete, brick, and stone.

Tightening too much can crack the surface.

Knowing these limits helps you avoid mistakes and install them safely.

Get your tools ready before starting. Being prepared makes the job easier and safer. Here’s what you’ll need:

Drill: Use a hammer drill with a masonry bit. This makes accurate holes in concrete or brick.

Measuring Tape: Measure the hole’s depth and position carefully.

Marker or Pencil: Mark where to drill for better accuracy.

Vacuum or Brush: Remove dust and debris from the drilled hole.

Wrench or Socket Set: Tighten the sleeve anchor properly.

Safety Gear: Wear goggles, gloves, and a dust mask for protection.

Using the right tools helps you follow instructions and avoid mistakes.

Safety is very important when using sleeve anchors. Small mistakes can cause big problems. Follow these tips to stay safe:

Clean the Hole Well: Dust or dirt in the hole can weaken the anchor. Use a vacuum or brush to clean it out.

Check the Anchor: Look for dirt, grease, or damage on the anchor. These can make it less strong.

Wear Safety Gear: Goggles protect your eyes from debris. Gloves keep your hands safe, and a dust mask stops you from breathing harmful particles.

Ask for Help: If you’re unsure, get help from someone experienced. Training lowers the chance of mistakes.

Don’t Over-Tighten: Tightening too much can crack the surface or harm the anchor. Stop when it feels secure.

By following these tips, you’ll avoid problems like having to redo the installation. Staying safe also ensures the anchors stay strong for a long time.

Tip: Check your tools and safety gear before starting. A quick check can save time and prevent issues later.

Before you start drilling, marking the correct drilling depth is crucial. This step ensures that the sleeve anchors fit securely and provide maximum holding power. Follow these simple steps to get it right:

Begin by identifying the exact locations where the anchors will go. Consider the load distribution and the structural integrity of the surface.

Use a chalk line or a marker to outline the spots for drilling. Make sure the spacing between the holes matches the project requirements.

Double-check your measurements. A small error here can lead to misaligned anchors, which might weaken the installation.

Select a hammer drill with a masonry bit that matches the diameter of the sleeve anchor. This ensures a snug fit.

Drill perpendicular to the surface, and make the hole slightly deeper than the anchor length—about 1/4 inch extra is ideal.

Pro Tip: Use a depth gauge or mark the drill bit with tape to avoid drilling too deep or too shallow.

Taking the time to mark the drilling depth accurately will save you from potential headaches later in the process.

Now that you've marked the spots, it's time to drill the holes. This step requires precision and the right technique to ensure the sleeve anchors hold firmly. Here's how to do it:

Attach the correct masonry bit to your hammer drill. The bit size should match the diameter of the sleeve anchor.

Position the drill perpendicular to the surface. This helps create a straight hole, which is essential for a secure fit.

Start drilling at a steady pace. Avoid applying too much pressure, as this can damage the drill bit or the surface.

Drill to the marked depth. If you're using tape on the bit as a guide, stop drilling when the tape reaches the surface.

Parameter | Description |

|---|---|

Rate of Penetration (ROP) | Maintain a consistent ROP for efficient drilling. |

Rotation Speed | Adjust the speed based on the hardness of the concrete or brick. |

Penetration Depth per Revolution | Ensure the depth matches the anchor's length for optimal performance. |

Initial Stage Characteristics | Expect faster drilling in the first 30mm of concrete, then slow down for better control. |

Safety Reminder: Always wear goggles and gloves while drilling. Concrete dust can irritate your eyes and skin.

Drilling the hole correctly is one of the most important installation steps. A clean, precise hole ensures the sleeve anchors perform as intended.

After drilling, cleaning the hole is a step you shouldn't skip. Dust and debris can weaken the bond between the sleeve anchor and the surface. Here's how to clean the hole effectively:

Start by using a shop vacuum to remove loose debris. This gets rid of most of the dust.

Follow up with compressed air to blast out any remaining particles. Attach a short length of tubing to a blower gun for better control.

For stubborn debris, use a modified wire sleeve or a small brush to loosen the dust before vacuuming again.

Did You Know? Using only a vacuum might not be enough. Combining it with air pressure ensures the hole is completely clean and ready for the anchor.

A clean hole is essential for a strong and secure installation. It allows the sleeve anchor to expand properly and hold firmly in place.

Once the hole is clean, you're ready to insert the sleeve anchor. This step is straightforward but requires attention to detail to ensure a secure fit. Here's how you can do it:

Prepare the Anchor: Take the sleeve anchor and inspect it for any visible damage. A damaged anchor won't hold properly, so replace it if needed.

Align the Anchor: Position the sleeve anchor over the hole. Make sure the threaded bolt is facing outward, as this is where you'll tighten it later.

Insert the Sleeve Anchor: Gently push the anchor into the hole. If it doesn't slide in easily, avoid forcing it. Instead, check if the hole is clean or if the anchor is the correct size.

Tap It In: Use a hammer to lightly tap the anchor until the sleeve is flush with the surface. Be careful not to hit it too hard, as this could damage the anchor or the surrounding material.

Tip: If you're working with a vertical surface, hold the anchor steady while tapping to prevent it from shifting.

By following these steps, you'll ensure the sleeve anchor is properly seated and ready for the next stage. A well-inserted anchor is the foundation of a strong and lasting installation.

Now comes the critical part—tightening the anchor. This step locks the sleeve in place and ensures the fixture stays secure. Here's how to do it right:

Choose the Right Tool: Use a 1-1/8" wrench or a socket wrench that fits snugly over the nut. A loose tool can slip and damage the anchor or your hands.

Turn the Nut: Begin tightening the nut by turning it clockwise. Make 2 to 4 full turns to snug the anchor into place.

Check the Torque: For optimal performance, tighten the anchor to a torque value between 60 and 90 ft./lbs. This ensures the sleeve expands fully without over-tightening.

Torque Guidelines | Details |

|---|---|

Maximum Torque | 60 - 90 ft./lbs. |

Wrench Size | 1-1/8" |

Turns Required | 2 to 4 full turns |

Test the Stability: Once tightened, give the fixture a gentle tug to ensure it's secure. If it wobbles, double-check the torque and make sure the anchor is properly seated.

Safety Note: Avoid over-tightening the nut. Too much force can crack the concrete or damage the anchor, reducing its holding power.

Tightening the anchor securely is the final step in the process. When done correctly, the sleeve anchor will provide a strong and reliable hold for your project.

Even with good planning, problems can happen when installing sleeve anchors. Don’t worry—most issues are simple to fix if you know what to do. Let’s look at some common problems and how to solve them.

A spinning anchor can be annoying. It happens when the sleeve anchor turns in the hole instead of locking in place. This makes the anchor weak and can ruin your project. Here’s how to fix it:

Use Vice Grips: Clamp vice grips onto the bolt to stop it from turning.

Apply Epoxy: If it still spins, take out the anchor. Add a little epoxy to the hole, put the anchor back, and let it dry before tightening.

Drill Out the Anchor: If nothing works, drill out the bad anchor. Replace it with an epoxy anchor for a stronger hold. Make the new hole slightly bigger for the epoxy.

Pro Tip: Don’t drill too close to other holes or cracks. Keep at least 6 inches away to protect the surface.

Spinning anchors are common, but these fixes can save time and make your installation secure.

Drilling the wrong depth is another common mistake. If the hole is too shallow, the anchor won’t fit. If it’s too deep, the anchor may not expand properly. Here’s how to fix these problems:

For Shallow Holes:

Drill the hole deeper to the correct size. Use tape on your drill bit or a depth gauge to avoid mistakes.

Clean the hole well before putting the anchor back in.

For Deep Holes:

Add non-shrink grout or epoxy to the bottom of the hole. This fills the extra space so the anchor can expand properly.

Let the filler dry before continuing.

Quick Tip: Always measure carefully before drilling. Taking extra time now can save you from redoing the work later.

Fixing drilling depth mistakes ensures your sleeve anchors hold strong and work as they should.

Over-tightening anchors can cause big problems. It puts too much pressure on the surface, which can crack or break it. Here’s how to avoid this:

Problem | Solution |

|---|---|

Surface Cracking | Tighten only to the recommended torque value. |

Stress Damage | Use a torque wrench for accurate force. |

Material Failure | Follow preload values for the material being fastened. |

Follow these steps to tighten anchors safely:

Use a torque wrench to control how much force you apply.

Stop tightening as soon as the anchor feels secure. Don’t add extra turns.

Check the manufacturer’s instructions for the right torque range. Most sleeve anchors need 60–90 ft./lbs. of torque.

Did You Know? Both under-tightening and over-tightening can weaken anchors. Aim for the right balance to get the best hold.

By being careful, you’ll protect the surface and keep your sleeve anchors strong for a long time.

Sleeve anchors are very useful for many projects. Indoors, they can hold up shelves, cabinets, or TVs on concrete or brick walls. They also work well for securing handrails or heavy mirrors.

Outside, sleeve anchors are great for tougher jobs. Use them to attach fences, gates, or outdoor lights to masonry. Stainless steel sleeve anchors are best outdoors because they don’t rust, even in bad weather. Whether building a patio or putting up a mailbox, these anchors stay strong.

Tip: Pick the right anchor material for your project. Stainless steel is best for outdoor use, while carbon steel works indoors.

Sleeve anchors are better than other fasteners for masonry. They create a strong hold in hard materials like concrete, brick, and stone. This makes them reliable for important projects.

They work by expanding inside the hole. Tightening the bolt pulls the cone-shaped end through the sleeve, making it press against the hole walls. This creates a secure grip without needing glue or tricky steps.

Sleeve anchors can also hold heavy items. Use them for hanging large art or securing equipment. They come in different sizes and materials, so you can choose the right one for your job.

Why Choose Sleeve Anchors? They’re simple to use, very strong, and perfect for medium- to heavyweight fixtures. For masonry, they’re a top choice.

Sleeve anchors are essential for attaching things to concrete or brick. If used properly, they hold strong and last a long time. Research shows they work well 50% to 90% of the time, based on materials and setup. This shows they are dependable for many tasks. Whether for building projects or home DIYs, they are very useful. Using them the right way keeps your items secure and your work durable.

Choose the size based on the item's weight. Heavier items need thicker anchors. Always check the manufacturer's load capacity for safety.

No, sleeve anchors are for one-time use. Once removed, they can't expand properly. Use new ones to ensure a strong hold.

Sleeve anchors work well on concrete, brick, and stone. Don't use them on wood or drywall, as they can damage softer materials.

This can happen if the hole is dirty or the anchor isn’t tight enough. Clean the hole well and tighten the anchor to the correct torque.

Stainless steel sleeve anchors resist rust, so they’re great outdoors. Carbon steel anchors are better for indoor projects.