- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

GB897

HNF

7318190000

Stainless Steel 304 316 Two Ends Double Ends Stud Bolt

Product Description

A stud bolt is a bolt without a head and with threads at both ends. It is usually used to connect two parts that need to be firmly fixed. It is common in flange and pipe connections. Stud bolts are fastened at both ends by nuts to provide high-strength connections. They are particularly suitable for use in environments with high pressure, high temperature or frequent vibration. Common materials include carbon steel, stainless steel and alloy steel to meet different application requirements. Due to its simple structure and high strength, it is widely used in the fields of petroleum, chemical industry, construction and machinery manufacturing to provide stable and reliable connections.

Advantages

- High strength: provides high fastening force, suitable for harsh environments.

- High temperature and high pressure resistance: suitable for high temperature and high pressure connection occasions.

- Easy to disassemble: easy to inspect and replace, no need to completely remove.

Disadvantages

- Complex installation: requires precise alignment and long installation time.

- Higher cost: special materials and processing increase costs.

- Large weight: when used for heavy connections, transportation and installation difficulties increase.

Product Details

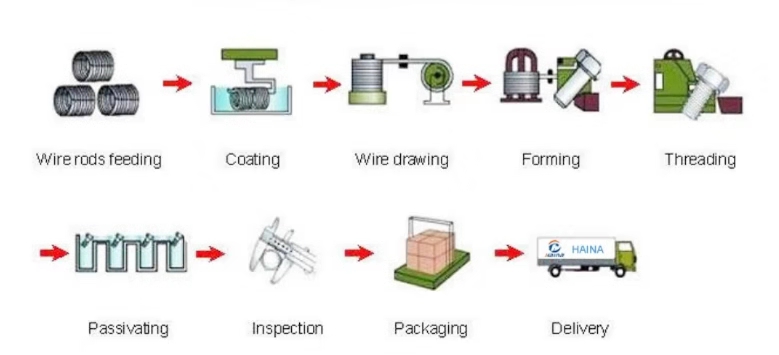

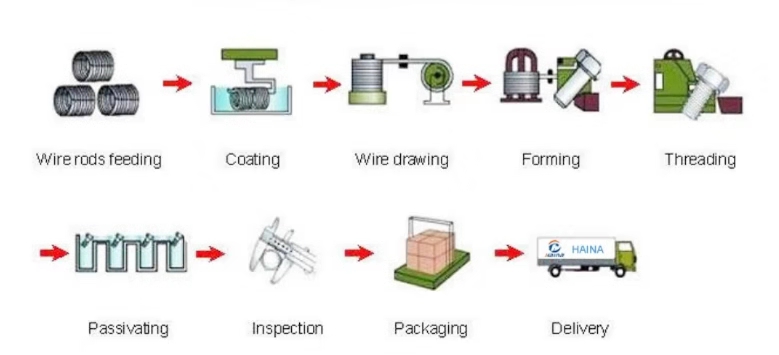

Production Process

Product Application

Stud Bolt is widely used for its high strength and reliability.

1. Pipe and flange connection: used for flange fastening in high-pressure pipelines and chemical equipment.

2. Oil and gas industry: suitable for equipment installation in harsh environments, withstanding high temperature and high pressure.

3. Construction and civil engineering: used for steel structure connection, providing high-strength fixation.

4. Machinery manufacturing: used for fixing heavy machinery parts such as engines and pumps.

5. Power plant equipment: used in boilers and high-pressure equipment to ensure stability.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.What is the difference between a stud and a threaded rod?

The main difference between studs and threaded rods is their length and purpose. Studs are usually shorter and have threads at both ends, with no threads or only a small amount of threads in the middle. They are used for double-sided fixing, such as the connection between flanges and mechanical parts. Threaded rods are threaded throughout and have a longer length. They can be cut as needed and are widely used in construction, installation, and maintenance for fixing, tightening, or structural reinforcement. Studs are suitable for precision connections, while threaded rods are more flexible and suitable for general fixing.

2.What is a double-ended stud?

A double-ended stud is a stud with threads on both ends, no threads or only a small number of threads in the middle, and is used to connect parts that need to be fixed on both sides. It is usually used to fix parts on a larger body, with one end screwed into the body and the other end connected to other parts through a nut to form a reliable connection. Double-ended studs are mostly used in occasions that require frequent loading and unloading or high precision, such as engines, mechanical equipment, and flange connections. Its structure is simple, provides high-strength fastening effect, and is easy to disassemble and maintain.

3.What is the purpose of a double stud?

The main function of a double-ended stud is to provide a strong double-sided connection, which is suitable for structural parts that require high-strength fixing. One end of the double-ended stud is screwed into the main material, and the other end is connected to other components through a nut, so that it can remain stable under high pressure or vibration environments. It is widely used in occasions such as machinery, automobiles, and construction that require disassembly and maintenance, such as fixing engines, flanges, and heavy machinery and equipment. The double-headed stud design makes loading and unloading easier, and there is no need to frequently replace the main material, which effectively extends the service life.

Stainless Steel 304 316 Two Ends Double Ends Stud Bolt

Product Description

A stud bolt is a bolt without a head and with threads at both ends. It is usually used to connect two parts that need to be firmly fixed. It is common in flange and pipe connections. Stud bolts are fastened at both ends by nuts to provide high-strength connections. They are particularly suitable for use in environments with high pressure, high temperature or frequent vibration. Common materials include carbon steel, stainless steel and alloy steel to meet different application requirements. Due to its simple structure and high strength, it is widely used in the fields of petroleum, chemical industry, construction and machinery manufacturing to provide stable and reliable connections.

Advantages

- High strength: provides high fastening force, suitable for harsh environments.

- High temperature and high pressure resistance: suitable for high temperature and high pressure connection occasions.

- Easy to disassemble: easy to inspect and replace, no need to completely remove.

Disadvantages

- Complex installation: requires precise alignment and long installation time.

- Higher cost: special materials and processing increase costs.

- Large weight: when used for heavy connections, transportation and installation difficulties increase.

Product Details

Production Process

Product Application

Stud Bolt is widely used for its high strength and reliability.

1. Pipe and flange connection: used for flange fastening in high-pressure pipelines and chemical equipment.

2. Oil and gas industry: suitable for equipment installation in harsh environments, withstanding high temperature and high pressure.

3. Construction and civil engineering: used for steel structure connection, providing high-strength fixation.

4. Machinery manufacturing: used for fixing heavy machinery parts such as engines and pumps.

5. Power plant equipment: used in boilers and high-pressure equipment to ensure stability.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.What is the difference between a stud and a threaded rod?

The main difference between studs and threaded rods is their length and purpose. Studs are usually shorter and have threads at both ends, with no threads or only a small amount of threads in the middle. They are used for double-sided fixing, such as the connection between flanges and mechanical parts. Threaded rods are threaded throughout and have a longer length. They can be cut as needed and are widely used in construction, installation, and maintenance for fixing, tightening, or structural reinforcement. Studs are suitable for precision connections, while threaded rods are more flexible and suitable for general fixing.

2.What is a double-ended stud?

A double-ended stud is a stud with threads on both ends, no threads or only a small number of threads in the middle, and is used to connect parts that need to be fixed on both sides. It is usually used to fix parts on a larger body, with one end screwed into the body and the other end connected to other parts through a nut to form a reliable connection. Double-ended studs are mostly used in occasions that require frequent loading and unloading or high precision, such as engines, mechanical equipment, and flange connections. Its structure is simple, provides high-strength fastening effect, and is easy to disassemble and maintain.

3.What is the purpose of a double stud?

The main function of a double-ended stud is to provide a strong double-sided connection, which is suitable for structural parts that require high-strength fixing. One end of the double-ended stud is screwed into the main material, and the other end is connected to other components through a nut, so that it can remain stable under high pressure or vibration environments. It is widely used in occasions such as machinery, automobiles, and construction that require disassembly and maintenance, such as fixing engines, flanges, and heavy machinery and equipment. The double-headed stud design makes loading and unloading easier, and there is no need to frequently replace the main material, which effectively extends the service life.