- All

- Product Name

- Product Keyword

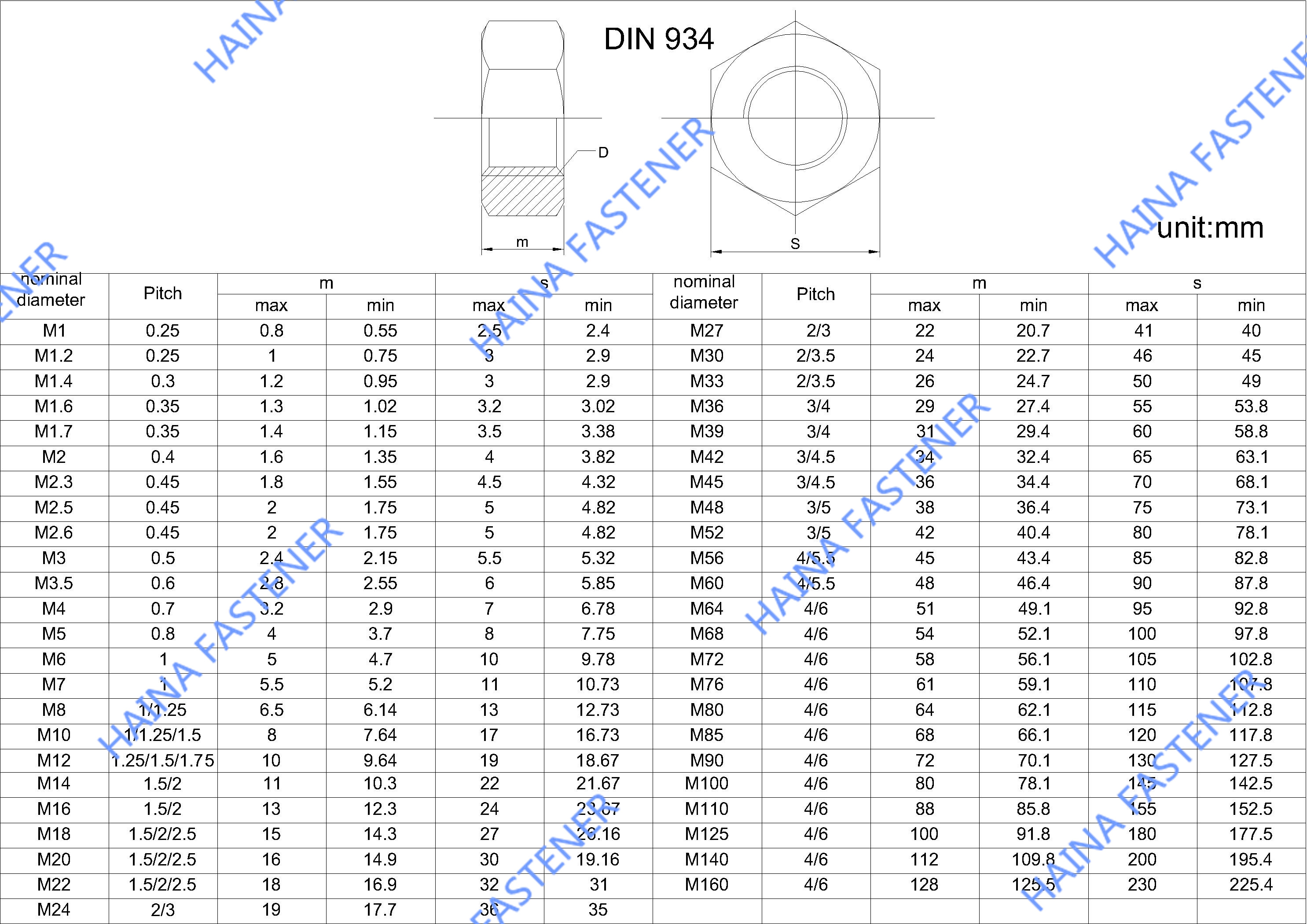

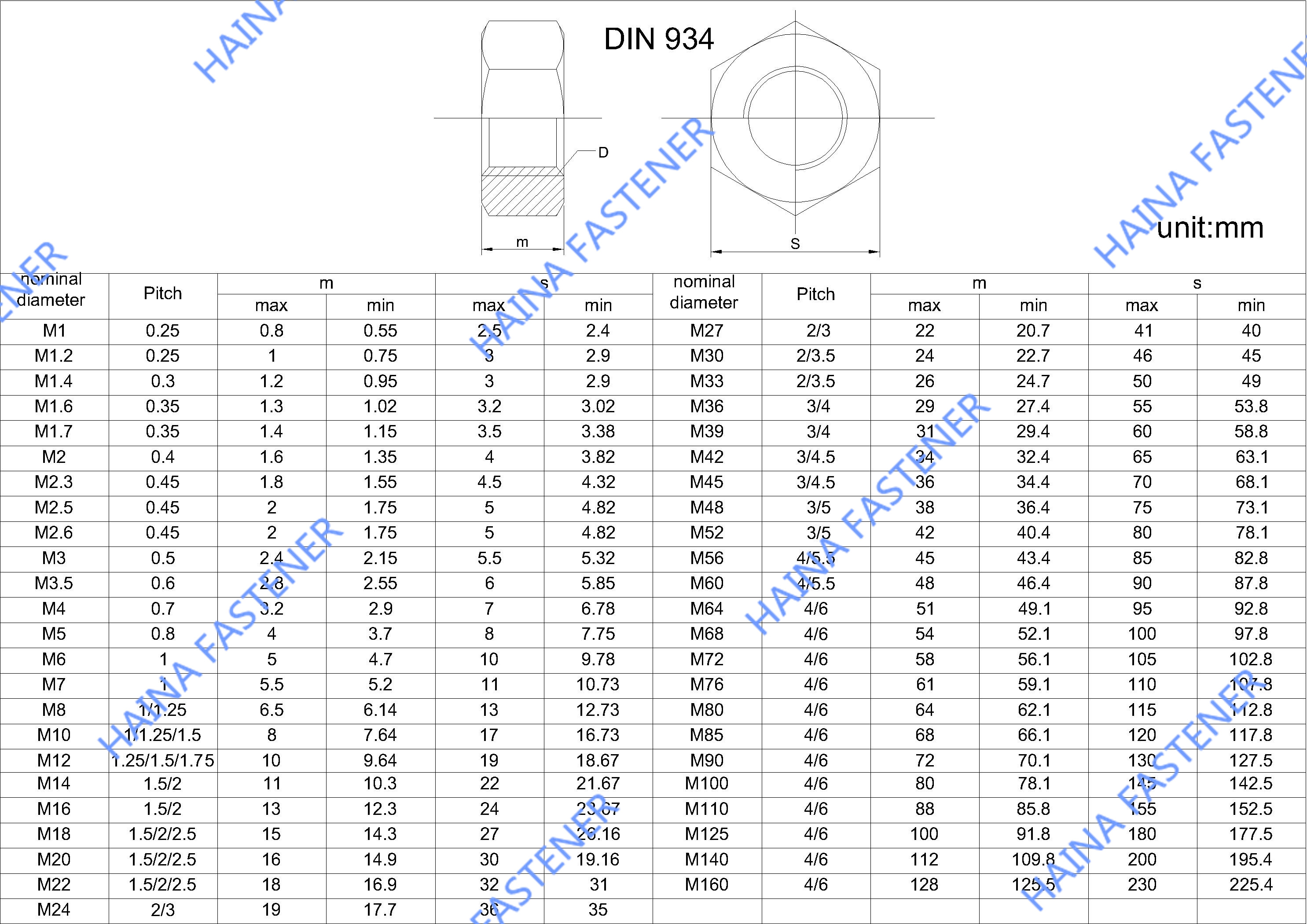

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

DIN934

HNF

HNF2021011502

A stainless - steel heavy - duty hexagonal nut is a nut made of stainless steel with a hexagonal shape. It has a greater thickness and higher load - bearing capacity compared to ordinary hexagonal nuts. It is mainly used in mechanical structures and equipment that require high fastening force and strength. By working in conjunction with bolts, it serves to fasten and connect components.

Production Process

High strength: Made of stainless steel and through special processing techniques, it has high strength and hardness. It can withstand large tensile forces and torques, and is not prone to deformation and fracture.

Good corrosion resistance: Stainless steel itself has excellent corrosion resistance. It can resist the erosion of various chemical substances, acid - base environments, and humid air, etc. It can be used for a long time in harsh working environments while maintaining good performance.

Aesthetic appearance: It has a smooth surface, uniform color, and a metallic texture. It can not only meet functional requirements but also improve the overall aesthetic of equipment or products to a certain extent.

Good machinability: It is easy to perform various machining operations such as drilling, tapping, and milling. It can be customized according to specific usage requirements to meet different installation and usage needs.

High reliability: Under heavy loads and harsh working conditions, it can maintain stable fastening performance, ensuring the reliability of connections and reducing potential safety hazards and equipment failures caused by loosening or breakage.

Long service life: Due to its good corrosion resistance and high strength, compared with nuts made of other materials, stainless - steel heavy - duty hexagonal nuts have a longer service life, which can reduce maintenance and replacement costs.

Wide range of applications: It can adapt to various working environments and media. Whether in high - temperature, low - temperature, humid, acid - base environments, or in various fields such as machinery, chemical engineering, and construction, it can perform well.

Machinery manufacturing: In various large - scale mechanical equipment, automobile manufacturing, shipbuilding, and other fields, it is used to connect and fasten important components such as engines, transmissions, and chassis to ensure the stable operation of the equipment.

Petrochemical industry: In the installation and maintenance of equipment such as pipelines, reactors, and towers in the petroleum exploration, refining, and chemical industries, it is used to connect pipeline flanges, equipment interfaces, etc., and can withstand the effects of high temperature, high pressure, and corrosive media.

Construction engineering: In the connection of steel structures in building structures and bridge construction, etc., it is used to connect structural components such as steel beams and columns to provide reliable connection strength.

Power industry: In power facilities such as power plants and substations, it is used to connect electrical equipment, busbars, etc., to ensure the safe and stable operation of the power transmission and distribution system.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.What is the difference between square and hex nuts?

Square nuts and hex nuts differ mainly in shape and purpose. Square nuts have four flat sides and are usually used in situations where they need to be clamped with a wrench from two sides; hex nuts have six sides and can be easily tightened or loosened with a hex wrench from multiple angles, which can better apply torque and are suitable for a wide range of applications. Hex nuts are easier to adjust and more flexible to use than square nuts due to their six-sided design, making them an industrial standard.

When would you use a hex nut?

Hex nuts are used in many situations. When two or more parts need to be connected, hex nuts can be used with bolts to achieve fastening. In the fields of machinery manufacturing, construction installation, and automobile maintenance, hex nuts are often used to ensure the firmness of the connection wherever there is a bolt connection.

What are the common applications for stainless steel hex nuts?

Stainless steel hex nuts are widely used in construction, machinery, automotive, marine, and furniture industries for securing bolts in place.

A stainless - steel heavy - duty hexagonal nut is a nut made of stainless steel with a hexagonal shape. It has a greater thickness and higher load - bearing capacity compared to ordinary hexagonal nuts. It is mainly used in mechanical structures and equipment that require high fastening force and strength. By working in conjunction with bolts, it serves to fasten and connect components.

Production Process

High strength: Made of stainless steel and through special processing techniques, it has high strength and hardness. It can withstand large tensile forces and torques, and is not prone to deformation and fracture.

Good corrosion resistance: Stainless steel itself has excellent corrosion resistance. It can resist the erosion of various chemical substances, acid - base environments, and humid air, etc. It can be used for a long time in harsh working environments while maintaining good performance.

Aesthetic appearance: It has a smooth surface, uniform color, and a metallic texture. It can not only meet functional requirements but also improve the overall aesthetic of equipment or products to a certain extent.

Good machinability: It is easy to perform various machining operations such as drilling, tapping, and milling. It can be customized according to specific usage requirements to meet different installation and usage needs.

High reliability: Under heavy loads and harsh working conditions, it can maintain stable fastening performance, ensuring the reliability of connections and reducing potential safety hazards and equipment failures caused by loosening or breakage.

Long service life: Due to its good corrosion resistance and high strength, compared with nuts made of other materials, stainless - steel heavy - duty hexagonal nuts have a longer service life, which can reduce maintenance and replacement costs.

Wide range of applications: It can adapt to various working environments and media. Whether in high - temperature, low - temperature, humid, acid - base environments, or in various fields such as machinery, chemical engineering, and construction, it can perform well.

Machinery manufacturing: In various large - scale mechanical equipment, automobile manufacturing, shipbuilding, and other fields, it is used to connect and fasten important components such as engines, transmissions, and chassis to ensure the stable operation of the equipment.

Petrochemical industry: In the installation and maintenance of equipment such as pipelines, reactors, and towers in the petroleum exploration, refining, and chemical industries, it is used to connect pipeline flanges, equipment interfaces, etc., and can withstand the effects of high temperature, high pressure, and corrosive media.

Construction engineering: In the connection of steel structures in building structures and bridge construction, etc., it is used to connect structural components such as steel beams and columns to provide reliable connection strength.

Power industry: In power facilities such as power plants and substations, it is used to connect electrical equipment, busbars, etc., to ensure the safe and stable operation of the power transmission and distribution system.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.What is the difference between square and hex nuts?

Square nuts and hex nuts differ mainly in shape and purpose. Square nuts have four flat sides and are usually used in situations where they need to be clamped with a wrench from two sides; hex nuts have six sides and can be easily tightened or loosened with a hex wrench from multiple angles, which can better apply torque and are suitable for a wide range of applications. Hex nuts are easier to adjust and more flexible to use than square nuts due to their six-sided design, making them an industrial standard.

When would you use a hex nut?

Hex nuts are used in many situations. When two or more parts need to be connected, hex nuts can be used with bolts to achieve fastening. In the fields of machinery manufacturing, construction installation, and automobile maintenance, hex nuts are often used to ensure the firmness of the connection wherever there is a bolt connection.

What are the common applications for stainless steel hex nuts?

Stainless steel hex nuts are widely used in construction, machinery, automotive, marine, and furniture industries for securing bolts in place.