- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2025-06-17 Origin: Site

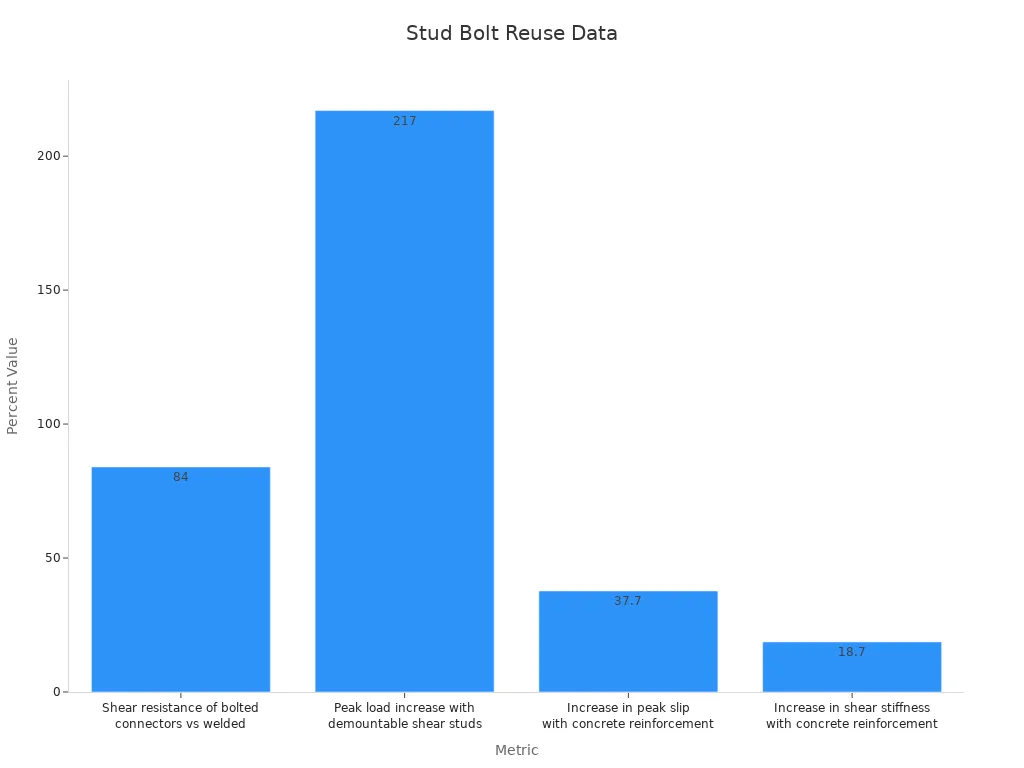

Stud bolts can only be reused if engineers confirm that bolt and fastener reuse is safe. Safety is always the top priority to consider. The type of bolt, how it was previously used, and its specific application all play a crucial role. These factors help determine whether a bolt can be safely reused. Simply inspecting a bolt does not guarantee its safety. Tests indicate that repeated bolt and fastener reuse can weaken the bolts over time. This weakening can reduce their effectiveness. The chart below illustrates the factors that influence whether bolts can be reused, highlighting the importance of strength and stiffness in bolt and fastener reuse decisions.

Engineers must say yes before bolts are reused. Rules like ASTM A325 and A490 tell us when reuse is okay. The main engineer checks each bolt’s type, grade, finish, and how it was put in. Here are the main rules for reuse:

ASTM A490 bolts and galvanized ASTM A325 bolts cannot be used again. They are not flexible enough for more than one use.

Plain ASTM A325 bolts can be reused if the nut turns by hand and the engineer agrees.

ASME PCC-1 2019 is a standard for checking and fixing bolts after use.

Bolts stretched too far should never be reused. They might break early.

Nuts and washers need their own checks. Used nuts should not be reused. Washers can be reused if they are not bent.

Engineers must think about safety, cost, and risk before saying yes to reuse.

Many companies use RAGAGEP rules. These rules put safety first.

⚠️ Note: Just looking at a bolt is not enough. Only a trained engineer can approve reuse after a full check.

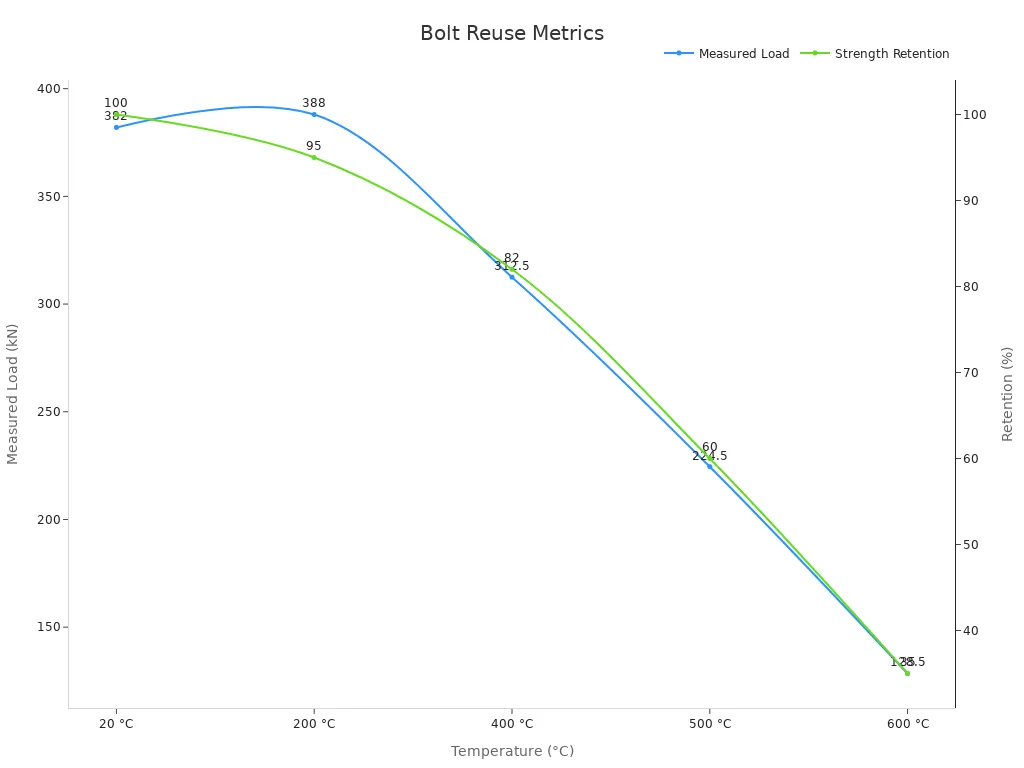

The bolt’s grade helps decide if it can be reused. ASTM A325 and A490 are common bolt grades. Each grade acts differently with stress, heat, and use. Tests show how strong bolts are in different situations:

Temperature (°C) | Measured Failure Load Range (kN) | Predicted Failure Load Accuracy | Strength Retention (%) | Notes |

|---|---|---|---|---|

20 (ambient) | ~372 to 392 | Within ±3.5% average difference | 100% (baseline) | Predicted and measured loads match well |

200 | ~384 to 392 | Small drop in reference load | Slight drop (~>90%) | Only a little strength lost |

400 | ~310 to 315 | Predicted within ~3.5% | ~82% | Some strength lost |

500 | ~216 to 233 | Predicted within ~7.6% max error | ~60% | A lot of strength lost |

600 | ~122 to 135 | Predicted within ~6% max error | ~35% | Most strength lost |

Both A325 and A490 bolts lose strength as heat goes up. A325 bolts lose strength a bit faster, but not by much. This data helps engineers decide if a bolt can be used again. They use these numbers to see if a bolt is still strong enough.

How a bolt is used affects if it can be reused. Important jobs, like bridges, need the safest bolts. Engineers almost never let bolts be reused here. For less important jobs, like scaffolding, reuse may be allowed.

Bolts in bridges or buildings must follow strict rules. Reuse is usually not allowed.

For machines that do not hold heavy things, engineers may allow reuse after checking.

The place matters too. Bolts in hot, chemical, or shaky places wear out faster. These bolts are less safe to reuse.

Engineers always look at what the bolt will do next. They check the bolt’s past, grade, and future work. This careful plan keeps everyone safe when reusing bolts.

Reusing bolts can make them weaker over time. Each time a bolt is reused, it holds things together less tightly. Tests show that bolts lose some of their grip after each use. This means reused bolts cannot hold as much weight as before. The way the threads are shaped also changes how fast they get weak. After many uses, old bolts may not be strong enough. Engineers must think about this before saying yes to reuse.

Note: A bolt might look okay, but it can still be too weak for important jobs.

Old bolts can act in strange ways. Tests show that reused bolts do not always last as long as new ones. Some reused bolts break sooner, even if they look fine. It is hard to guess how long a used bolt will last. Things like past damage or wrong installation can make reused bolts fail. This is why reusing bolts is risky when safety is very important.

Using new and old bolts together can cause problems.

Different metals touching can rust, especially if wet.

Steel with aluminum or copper with zinc are risky pairs.

Salt, dirt, and big temperature changes make rust worse.

Special coatings and careful design can help stop these problems.

Good installation and regular checks help keep bolts safe.

Mixing old and new bolts can hurt the whole structure. Engineers should not mix bolts unless they know it is safe.

Inspectors follow strict steps before any fasteners can be safely reused. They use standards like ASME B1.3M and Federal Standard H28 Document 20 to check if each bolt meets size and shape rules. The process includes:

Inspectors look for cracks or flaws on the surface. They use Liquid Penetrant or Magnetic Particle testing to find hidden cracks.

They check exposed threads for damage or wear. A thread gauge helps confirm the threads still fit the standard.

Inspectors compare the bolt’s shape and size to the original specifications.

They review if the fasteners stretched too much during the last use. If a bolt stretched past its yield point, it cannot be reused.

Only a trained professional can decide if a bolt passes these checks. Visual inspection alone does not guarantee safety.

The threads on fasteners must stay sharp and undamaged. Inspectors look for signs of flattening, galling, or cross-threading. If threads show any sign of wear, the bolt cannot be used again. They use a thread gauge to test if the threads match the original pattern. Even small changes in thread shape can cause fasteners to fail under load. Used studs with damaged threads often slip or break when tightened. Engineers always reject bolts with poor thread condition.

Field testing gives extra proof that fasteners will work as needed. Rotational Capacity (ROCAP) testing checks if the bolt and nut can turn together without stripping. This test shows if the assembly can reach the right tension. ROCAP testing also checks if the lubricant works and if all parts fit together. Standards like ASTM A325 and ASTM F3125 explain how to run these tests. Experts perform ROCAP testing on-site for each batch of fasteners. The American Institute of Steel Construction allows plain finish A325 bolts to be reused after passing these tests. However, they do not allow A490 bolts to be reused because of safety risks.

Inspection must go beyond appearance. Only professional assessment and testing can confirm if fasteners are safe for reuse.

Industry rules tell us when bolts can be used again. The RCSC gives the main rules for reusing bolts. Their Section 2.3.3 explains when reuse is safe. Here are some important points:

Uncoated F3125 Grade A325 bolts can be reused if an engineer says yes.

Galvanized bolts and F3125 Grade A490 bolts should not be reused.

Snugged F3125 Grade A325 bolts are often okay to reuse.

Snugged F3125 Grade A490 bolts and galvanized Grade A325 bolts can only be reused if tightened by hand or gently with a tool.

Bolts can only be reused if they are not stretched too far. Engineers check this by putting a nut on the bolt.

This check does not work for galvanized bolts because their threads are different.

ASME rules do not say much about reusing stud bolts, so RCSC rules are used instead.

ASTM A193 and ASTM A194 talk about materials and how to put bolts in, not about reuse.

Always ask the project engineer before reusing any bolts.

Engineers know some bolts cannot be reused. Grade 8 bolts can be reused if they are not bent or stretched. Torque-to-yield bolts that stretch too much should never be reused. Bolts are usually tightened to about 90% of their strength. Sometimes, tools can make bolts change shape a little. Rust, dirt, or shaking can make bolts weaker and unsafe to reuse. Lubricants help protect threads but need special care. Most bolts do not have a record of use, so engineers may not know their past. For less important jobs, reuse is possible if bolts are checked and tightened right. ASTM A490 bolts and galvanized A325 bolts are almost never reused. SAE J429 Grade 8 bolts can be reused if tightened within safe limits.

Tests in refineries show reused bolts can act in strange ways. Tiny thread damage can make bolts not work right. This makes reusing bolts risky. But there are two special cases:

Studs that are pulled tight, not twisted, can be reused safely. Pulling avoids problems with twisting.

Studs and nuts with fixed threads, repaired by special tools, can also be reused. Fixing the threads helps them work well again.

These rules come from real tests and experience. With the right steps, some bolts can be reused and still be safe.

Choosing to reuse a bolt or buy a new one is about money and safety.

Most companies say to read the instructions before making a choice.

Always check each bolt for damage or if it has stretched.

Some bolts, like head bolts, are made to be used once.

These bolts stretch when used and get weaker.

Engineers use a cost-benefit plan to help decide.

Here is a simple list:

Always read the rules for each job.

Look for any damage or stretching on the bolt.

Many a325 bolts are made for one use only.

The engine’s age or how much it worked matters.

Replacing a bolt costs less than fixing big problems.

Changing a325 bolts and other important bolts is cheap.

It helps stop big repairs or dangerous accidents.

Stopping work can cost a lot of money every hour.

If a bolt breaks, the whole system may need to stop.

This can slow down work, hurt safety, and upset customers.

Using a new a325 bolt lowers the chance of surprise stops.

If an old bolt breaks, fixing it takes longer and costs more.

Here is a simple table:

Scenario | Downtime (hours) | Repair Cost ($) | Risk Level |

|---|---|---|---|

New a325 bolt used | 1 | 500 | Low |

Reused bolt fails | 8 | 5,000 | High |

⏳ New bolts, like a325, help keep stops short and costs low.

Engineers think about saving a little money by reusing bolts.

But safety and trust are more important than small savings.

Stud bolts can be reused, but only if engineers say yes.

Safety is the most important thing to think about.

Here are some simple rules:

Only use bolts again if they were not tightened too much or damaged by heat or rust.

Do not mix old bolts with new ones. Hidden problems can make them break.

Do not reuse bolts that have paint, oil, or have been changed.

Only reuse bolts in places made for it. Change them if you see any damage.

Always ask experts and follow the rules. For important jobs, new bolts are safest and help stop big problems.

Engineers cannot always approve reuse. They must check the bolt’s grade, past use, and condition. Safety standards guide every decision. Some bolts, like ASTM A490, never qualify for reuse.

No set number exists. Each reuse weakens the bolt. Engineers inspect and test each bolt before every reuse. They stop reuse if the bolt shows damage or loss of strength.

Inspectors look for cracks, rust, bent shapes, or damaged threads. Any of these signs mean the bolt cannot be reused. Even small flaws can cause failure.

Mixing new and reused bolts is unsafe. Different strengths and wear levels can cause uneven load sharing. This increases the risk of failure.

Yes. Engineers use tests like ROCAP and thread gauges. These tests check if the bolt can reach the right tension and if threads match standards.