- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HNF

HINA2025020503

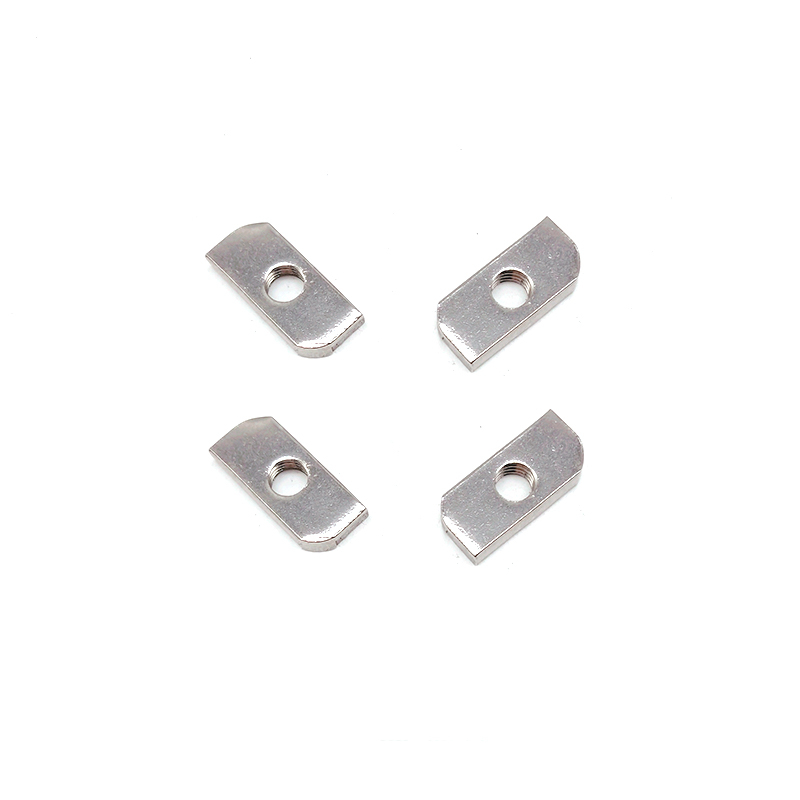

A diamond nut is a nut with a diamond shape, usually used in conjunction with a T-slot. It can be inserted vertically into the T-slot and used to fasten and connect components by cooperating with bolts, etc. It plays the role of fixing different components on the T-slot structure in mechanical connection.

Easy installation: It can be directly inserted vertically into the T-slot, and the installation process is simple and fast, without complicated operations and additional tools, which can save installation time and labor costs and improve work efficiency.

Accurate positioning: When used in conjunction with the T-slot, it can achieve accurate positioning, ensure the accurate position of the installed components, and help improve the assembly accuracy and stability of the entire equipment or structure.

Easy disassembly: When disassembly is required, just loosen the bolts that match it, and the diamond nut can be easily removed from the T-slot, which is convenient for equipment repair, maintenance and component replacement.

Strong bearing capacity: It is generally made of high-strength steel and other materials. After appropriate heat treatment and processing technology, it has high strength and rigidity, can withstand large loads, and is suitable for occasions with requirements for bearing capacity.

Good adaptability: It can adapt to different working environments and working conditions. For example, it can still maintain good fastening performance and is not easy to loosen under harsh conditions such as vibration and impact.

Machine tool equipment: It is often used to fix and connect the workbench, fixtures and other components of the machine tool. Through cooperation with the T-slot, the position of the fixtures and other components can be easily adjusted and fixed to ensure processing accuracy.

Automated production line: In automated production equipment, it is used to connect and fix various conveyor lines, robotic arms, tooling fixtures and other components to ensure stable operation and precise movement of the equipment.

Industrial aluminum profile frame: In the frame structure built with industrial aluminum profiles, it is a commonly used connection accessory that can quickly and firmly connect aluminum profiles and other components together, which is convenient for assembly and disassembly. It is widely used in the construction of protective fences, workbenches, material racks and other facilities in factories.

Mold manufacturing: During the installation and commissioning of the mold, it can be used to fix the mold on the workbench of equipment such as injection molding machines and stamping machines to ensure the stability and position accuracy of the mold during the working process.

Other mechanical structures: It can also be applied to various mechanical structures that need to connect and fix components through T-slots, such as the connection of bases, brackets and other components of some large mechanical equipment.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

1. What is a rhombic nut?

A rhombic nut is a type of nut with a rhombus-shaped head. It is designed for specific applications where space constraints or unique installation requirements are present. The rhombic shape allows for easier handling and installation in certain mechanical assemblies.

2. What are the common materials used for rhombic nuts?

Rhombic nuts are typically made from materials such as stainless steel, brass, and carbon steel. Stainless steel is preferred for its corrosion resistance, while brass offers good conductivity and corrosion resistance.

3. What are the common applications of rhombic nuts?

Rhombic nuts are used in various industrial applications, including mechanical assemblies, automotive parts, and electrical equipment. Their unique shape makes them suitable for installations where standard hexagonal or square nuts may not fit.

A diamond nut is a nut with a diamond shape, usually used in conjunction with a T-slot. It can be inserted vertically into the T-slot and used to fasten and connect components by cooperating with bolts, etc. It plays the role of fixing different components on the T-slot structure in mechanical connection.

Easy installation: It can be directly inserted vertically into the T-slot, and the installation process is simple and fast, without complicated operations and additional tools, which can save installation time and labor costs and improve work efficiency.

Accurate positioning: When used in conjunction with the T-slot, it can achieve accurate positioning, ensure the accurate position of the installed components, and help improve the assembly accuracy and stability of the entire equipment or structure.

Easy disassembly: When disassembly is required, just loosen the bolts that match it, and the diamond nut can be easily removed from the T-slot, which is convenient for equipment repair, maintenance and component replacement.

Strong bearing capacity: It is generally made of high-strength steel and other materials. After appropriate heat treatment and processing technology, it has high strength and rigidity, can withstand large loads, and is suitable for occasions with requirements for bearing capacity.

Good adaptability: It can adapt to different working environments and working conditions. For example, it can still maintain good fastening performance and is not easy to loosen under harsh conditions such as vibration and impact.

Machine tool equipment: It is often used to fix and connect the workbench, fixtures and other components of the machine tool. Through cooperation with the T-slot, the position of the fixtures and other components can be easily adjusted and fixed to ensure processing accuracy.

Automated production line: In automated production equipment, it is used to connect and fix various conveyor lines, robotic arms, tooling fixtures and other components to ensure stable operation and precise movement of the equipment.

Industrial aluminum profile frame: In the frame structure built with industrial aluminum profiles, it is a commonly used connection accessory that can quickly and firmly connect aluminum profiles and other components together, which is convenient for assembly and disassembly. It is widely used in the construction of protective fences, workbenches, material racks and other facilities in factories.

Mold manufacturing: During the installation and commissioning of the mold, it can be used to fix the mold on the workbench of equipment such as injection molding machines and stamping machines to ensure the stability and position accuracy of the mold during the working process.

Other mechanical structures: It can also be applied to various mechanical structures that need to connect and fix components through T-slots, such as the connection of bases, brackets and other components of some large mechanical equipment.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

1. What is a rhombic nut?

A rhombic nut is a type of nut with a rhombus-shaped head. It is designed for specific applications where space constraints or unique installation requirements are present. The rhombic shape allows for easier handling and installation in certain mechanical assemblies.

2. What are the common materials used for rhombic nuts?

Rhombic nuts are typically made from materials such as stainless steel, brass, and carbon steel. Stainless steel is preferred for its corrosion resistance, while brass offers good conductivity and corrosion resistance.

3. What are the common applications of rhombic nuts?

Rhombic nuts are used in various industrial applications, including mechanical assemblies, automotive parts, and electrical equipment. Their unique shape makes them suitable for installations where standard hexagonal or square nuts may not fit.