- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

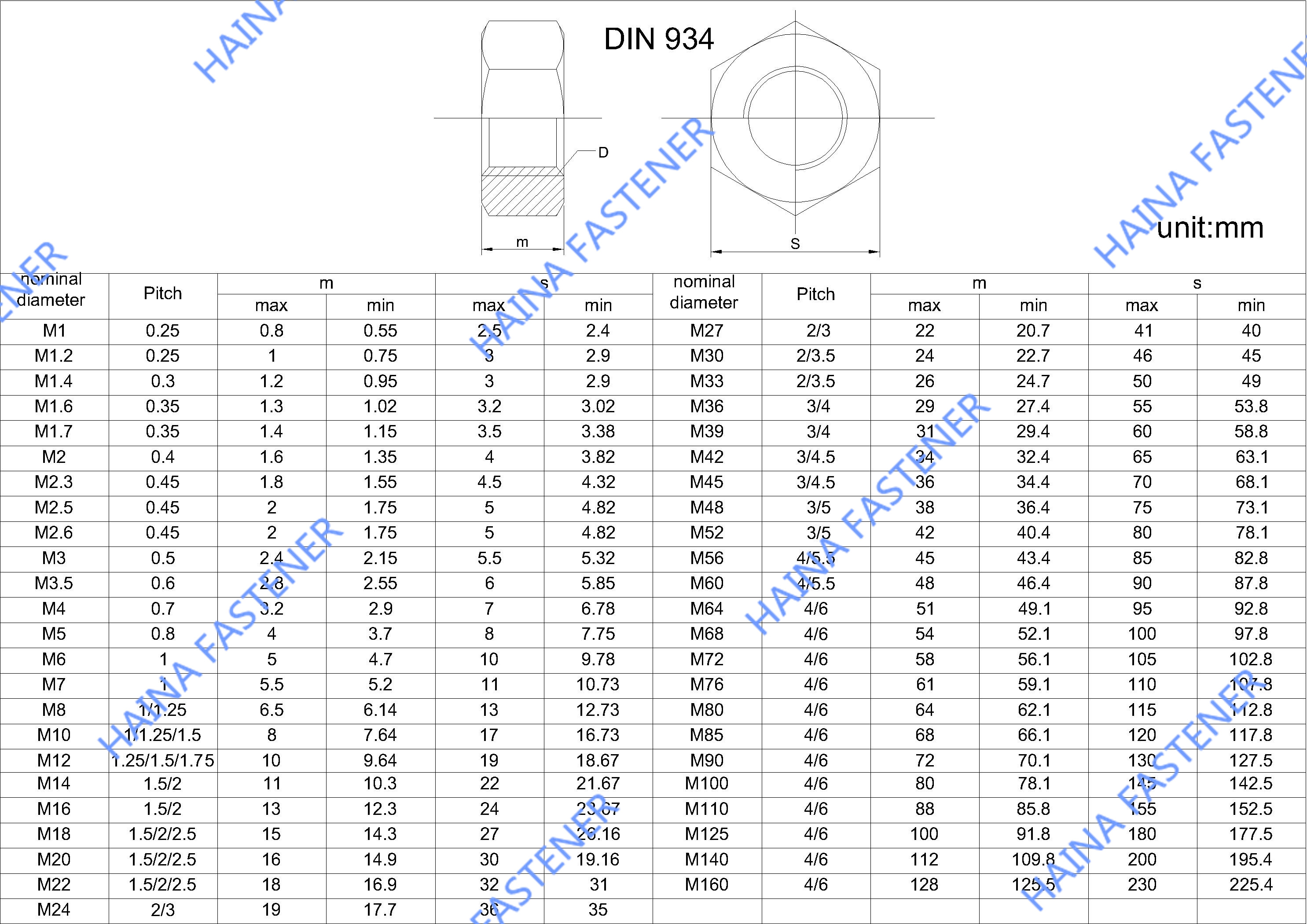

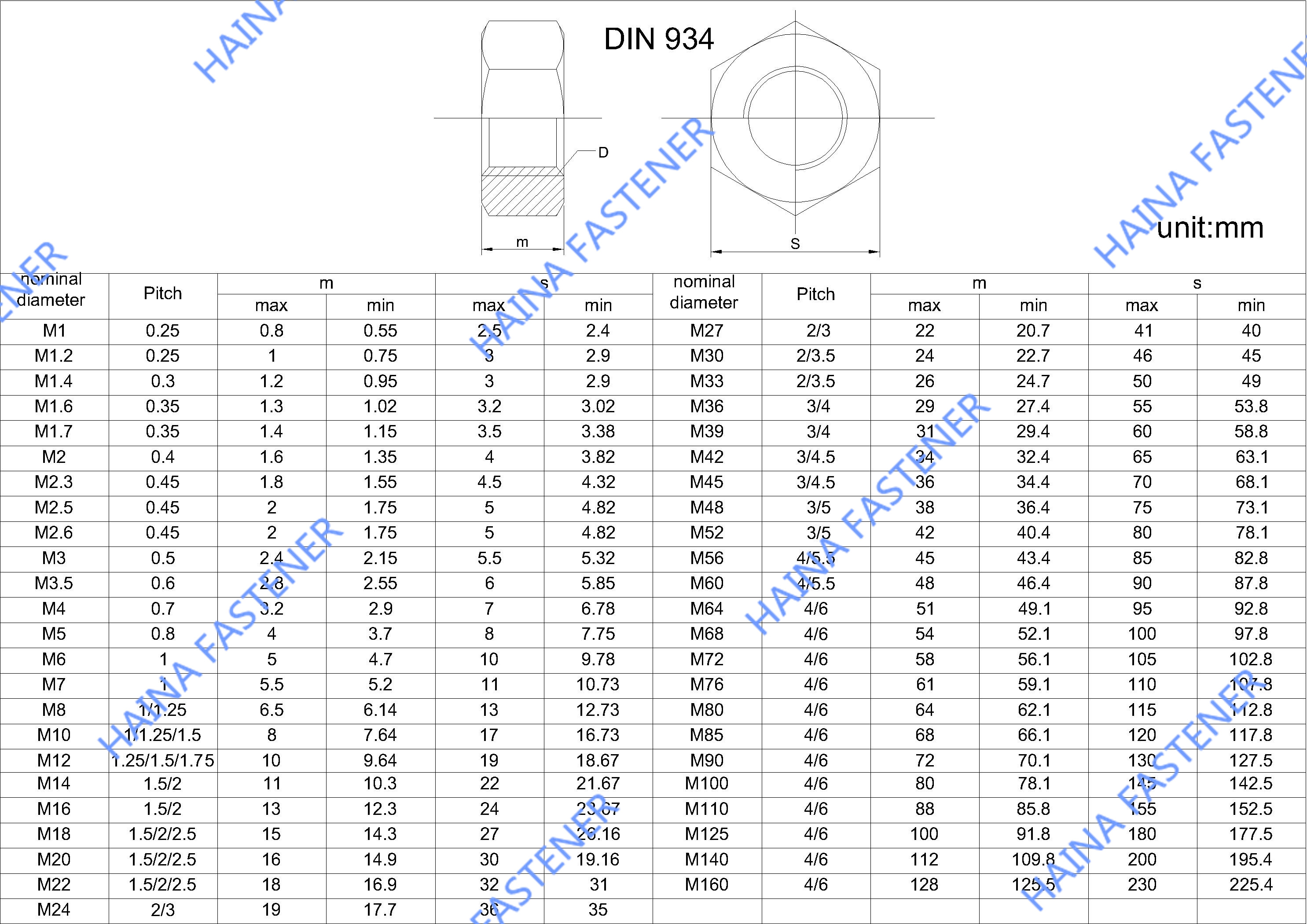

DIN934

HNF

HINA2025012302

Zinc-nickel alloy hexagonal nut is a hexagonal nut with zinc and nickel as the main alloy components, and a zinc-nickel alloy coating is formed on the surface of the nut through a specific process. On the basis of maintaining the basic shape and function of the hexagonal nut, it uses electroplating, hot-dip plating and other methods to attach a layer of zinc-nickel alloy coating with specific properties to the surface of the nut, thereby giving the nut better performance.

High corrosion resistance: The zinc-nickel alloy coating has better corrosion resistance than pure zinc coating, and can effectively resist the erosion of air, moisture, acid and alkali, etc. It can still maintain good performance in harsh environments, greatly extending the service life of the nut.

Good wear resistance: The zinc-nickel alloy coating has a higher hardness, which makes the nut surface have better wear resistance. During frequent loading and unloading and use, it can reduce wear and maintain the accuracy and connection performance of the nut.

Excellent temperature resistance: Compared with ordinary nuts, zinc-nickel alloy hexagonal nuts can maintain stable performance at higher temperatures, are not prone to deformation or performance degradation, and can adapt to a variety of high-temperature working environments.

Good conductivity: Zinc-nickel alloy has good conductivity. In some occasions where electrical performance is required, the use of zinc-nickel alloy hexagonal nuts can ensure good electrical connection, reduce resistance, and reduce power loss.

Good environmental performance: The zinc-nickel alloy process is relatively environmentally friendly, and less pollutants are generated during the production process, which meets the requirements of modern industry for environmental protection, and the alloy itself does not contain heavy metals and other substances that are harmful to the environment and human body.

Automobile manufacturing: It is widely used in the connection and fastening of automobile engines, chassis, body and other parts, such as the assembly of engine cylinders, the fixing of chassis suspension systems, etc. Its high corrosion resistance and good mechanical properties can ensure the safe driving of automobiles under various road conditions and environments.

Electronic appliances: In the production of electronic equipment, it is used for the fixing of circuit boards and the assembly of electrical housings. Good conductivity and corrosion resistance can ensure the stability and reliability of electronic equipment and prevent problems such as poor contact caused by corrosion.

Aerospace: Due to its excellent performance, it also has important applications in the aerospace field, such as the connection of aircraft engine components and the fastening of spacecraft structural parts, which can meet the requirements of aerospace equipment for high performance and high reliability of parts.

Shipbuilding: The marine environment where ships are located is highly corrosive. Zinc-nickel alloy hexagonal nuts can be used for ship hull structure connection, deck equipment fixation, etc., which can effectively resist seawater erosion and ensure the structural safety of ships and the normal operation of equipment.

Power industry: In power transmission and distribution equipment, it is used for the connection and fixation of poles, towers, etc., as well as the internal fastening of electrical equipment. Its good conductivity and corrosion resistance help to ensure the stable operation of the power system and reduce maintenance costs.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

How to choose the right model for carbon steel hexagonal nuts?

Select the strength grade according to the use scenario and load requirements; determine the specifications according to the thread size of the connecting parts; consider the working environment, such as ordinary carbon steel can be selected in dry environments, and carbon steel hexagonal nuts with surface treatment should be selected in humid or corrosion-risk environments.

Where can carbon steel hexagonal nuts be used?

Widely used in machinery manufacturing, construction, automobiles, furniture and other industries. Connect various parts in machinery manufacturing; use steel structure connections in the construction field; use automobile manufacturing to assemble engines, chassis and other parts; use furniture manufacturing to fix frames and plates.

Zinc-nickel alloy hexagonal nut is a hexagonal nut with zinc and nickel as the main alloy components, and a zinc-nickel alloy coating is formed on the surface of the nut through a specific process. On the basis of maintaining the basic shape and function of the hexagonal nut, it uses electroplating, hot-dip plating and other methods to attach a layer of zinc-nickel alloy coating with specific properties to the surface of the nut, thereby giving the nut better performance.

High corrosion resistance: The zinc-nickel alloy coating has better corrosion resistance than pure zinc coating, and can effectively resist the erosion of air, moisture, acid and alkali, etc. It can still maintain good performance in harsh environments, greatly extending the service life of the nut.

Good wear resistance: The zinc-nickel alloy coating has a higher hardness, which makes the nut surface have better wear resistance. During frequent loading and unloading and use, it can reduce wear and maintain the accuracy and connection performance of the nut.

Excellent temperature resistance: Compared with ordinary nuts, zinc-nickel alloy hexagonal nuts can maintain stable performance at higher temperatures, are not prone to deformation or performance degradation, and can adapt to a variety of high-temperature working environments.

Good conductivity: Zinc-nickel alloy has good conductivity. In some occasions where electrical performance is required, the use of zinc-nickel alloy hexagonal nuts can ensure good electrical connection, reduce resistance, and reduce power loss.

Good environmental performance: The zinc-nickel alloy process is relatively environmentally friendly, and less pollutants are generated during the production process, which meets the requirements of modern industry for environmental protection, and the alloy itself does not contain heavy metals and other substances that are harmful to the environment and human body.

Automobile manufacturing: It is widely used in the connection and fastening of automobile engines, chassis, body and other parts, such as the assembly of engine cylinders, the fixing of chassis suspension systems, etc. Its high corrosion resistance and good mechanical properties can ensure the safe driving of automobiles under various road conditions and environments.

Electronic appliances: In the production of electronic equipment, it is used for the fixing of circuit boards and the assembly of electrical housings. Good conductivity and corrosion resistance can ensure the stability and reliability of electronic equipment and prevent problems such as poor contact caused by corrosion.

Aerospace: Due to its excellent performance, it also has important applications in the aerospace field, such as the connection of aircraft engine components and the fastening of spacecraft structural parts, which can meet the requirements of aerospace equipment for high performance and high reliability of parts.

Shipbuilding: The marine environment where ships are located is highly corrosive. Zinc-nickel alloy hexagonal nuts can be used for ship hull structure connection, deck equipment fixation, etc., which can effectively resist seawater erosion and ensure the structural safety of ships and the normal operation of equipment.

Power industry: In power transmission and distribution equipment, it is used for the connection and fixation of poles, towers, etc., as well as the internal fastening of electrical equipment. Its good conductivity and corrosion resistance help to ensure the stable operation of the power system and reduce maintenance costs.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

How to choose the right model for carbon steel hexagonal nuts?

Select the strength grade according to the use scenario and load requirements; determine the specifications according to the thread size of the connecting parts; consider the working environment, such as ordinary carbon steel can be selected in dry environments, and carbon steel hexagonal nuts with surface treatment should be selected in humid or corrosion-risk environments.

Where can carbon steel hexagonal nuts be used?

Widely used in machinery manufacturing, construction, automobiles, furniture and other industries. Connect various parts in machinery manufacturing; use steel structure connections in the construction field; use automobile manufacturing to assemble engines, chassis and other parts; use furniture manufacturing to fix frames and plates.