- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HINA

HINA2024120201

Definition and purpose of blackening

- Blackening is a metal surface treatment process. For T-bolts, blackening is to form a black oxide film on the bolt surface by chemical or electrochemical methods. The main purpose is to improve the anti-rust ability of the bolt, because this oxide film can isolate air and moisture and slow down the corrosion rate of the bolt. At the same time, the appearance of the bolt after blackening is black, which is more beautiful and has a certain decorative effect.

Methods of blackening

Chemical blackening method: This is a more commonly used method. It is to soak the T-bolt in a solution containing an oxidant (such as sodium nitrite, etc.) and an alkali (such as sodium hydroxide) under certain temperature and time conditions to cause a chemical reaction on the bolt surface to generate a black magnetic iron oxide (\(Fe_3O_4\)) film. For example, in the traditional alkaline oxidation blackening process, the solution temperature is generally controlled at around 135-145℃, and the treatment time may vary from tens of minutes to several hours depending on factors such as the material and size of the bolt. - Electrochemical blackening method: This method uses the T-bolt as the anode in the electrolyte to form a black oxide film on the bolt surface through electrolysis. Its advantage is that the thickness and quality of the oxide film can be controlled more accurately, but the equipment and process are relatively complex.

Machinery industry: In the assembly of machine tools, engineering machinery and other equipment, blackened T-bolts are widely used. For example, on the workbench of the machine tool, the use of blackened T-bolts to fix components such as fixtures can not only ensure the firmness of the connection, but also make the overall appearance of the machine tool more coordinated.

- Assembly of automotive parts: In the fixing of some parts in the engine compartment of the car, or the installation of automotive interior parts, blackened T-bolts can provide good rust prevention and aesthetic effects. For example, after the T-bolts that fix the car seat are blackened, they can prevent rust and match the color of the car interior more reasonably.

- Construction industry: In the connection of metal structural parts of the building, such as the installation of some metal railings, shutters, etc., blackened T-bolts can provide stable connections while enhancing rust prevention and meeting the aesthetic requirements of the building's appearance.

Anti-rust performance: The anti-rust ability of T-bolts after blackening treatment is significantly improved in general environments. For example, in indoor environments with low relative humidity or outdoor environments with certain protection, the blackening layer can effectively prevent the bolts from rusting and extend the service life of the bolts. However, in some harsh corrosive environments (such as high humidity and high salinity environments), blackened bolts may also need to be combined with other protective measures (such as oiling, etc.) to enhance the anti-rust effect.

- Wear resistance: The surface oxide film after blackening treatment can also improve the wear resistance of the bolts to a certain extent. When the bolts and nuts or other parts rub against each other during installation and removal, this oxide film can play a certain wear-resistant role and reduce the wear on the bolt surface.

- Appearance: The black appearance makes the T-bolts look more unified and beautiful. In some occasions where there are requirements for the appearance of equipment, such as the fixing of precision instrument shells and the assembly of display equipment, blackened T-bolts can better meet visual needs.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

1.What is a T bolt used for?

A T-bolt is used for fastening components in slots or grooves, commonly in applications like industrial frames, machinery, or rail systems. Its T-shaped head provides a secure, adjustable connection.

2.Where are T-bolts used?

T-bolts are used in industrial assembly, machinery, construction, rail systems, and solar panel mounting, where secure, adjustable fastening in slots or grooves is needed.

3.How do you install a T bolt?

To install a T-bolt:

Insert the T-shaped head into a compatible slot or groove. Align the bolt and adjust its position as needed. Tighten the nut or fastener on the threaded end to secure it in place.

Definition and purpose of blackening

- Blackening is a metal surface treatment process. For T-bolts, blackening is to form a black oxide film on the bolt surface by chemical or electrochemical methods. The main purpose is to improve the anti-rust ability of the bolt, because this oxide film can isolate air and moisture and slow down the corrosion rate of the bolt. At the same time, the appearance of the bolt after blackening is black, which is more beautiful and has a certain decorative effect.

Methods of blackening

Chemical blackening method: This is a more commonly used method. It is to soak the T-bolt in a solution containing an oxidant (such as sodium nitrite, etc.) and an alkali (such as sodium hydroxide) under certain temperature and time conditions to cause a chemical reaction on the bolt surface to generate a black magnetic iron oxide (\(Fe_3O_4\)) film. For example, in the traditional alkaline oxidation blackening process, the solution temperature is generally controlled at around 135-145℃, and the treatment time may vary from tens of minutes to several hours depending on factors such as the material and size of the bolt. - Electrochemical blackening method: This method uses the T-bolt as the anode in the electrolyte to form a black oxide film on the bolt surface through electrolysis. Its advantage is that the thickness and quality of the oxide film can be controlled more accurately, but the equipment and process are relatively complex.

Machinery industry: In the assembly of machine tools, engineering machinery and other equipment, blackened T-bolts are widely used. For example, on the workbench of the machine tool, the use of blackened T-bolts to fix components such as fixtures can not only ensure the firmness of the connection, but also make the overall appearance of the machine tool more coordinated.

- Assembly of automotive parts: In the fixing of some parts in the engine compartment of the car, or the installation of automotive interior parts, blackened T-bolts can provide good rust prevention and aesthetic effects. For example, after the T-bolts that fix the car seat are blackened, they can prevent rust and match the color of the car interior more reasonably.

- Construction industry: In the connection of metal structural parts of the building, such as the installation of some metal railings, shutters, etc., blackened T-bolts can provide stable connections while enhancing rust prevention and meeting the aesthetic requirements of the building's appearance.

Anti-rust performance: The anti-rust ability of T-bolts after blackening treatment is significantly improved in general environments. For example, in indoor environments with low relative humidity or outdoor environments with certain protection, the blackening layer can effectively prevent the bolts from rusting and extend the service life of the bolts. However, in some harsh corrosive environments (such as high humidity and high salinity environments), blackened bolts may also need to be combined with other protective measures (such as oiling, etc.) to enhance the anti-rust effect.

- Wear resistance: The surface oxide film after blackening treatment can also improve the wear resistance of the bolts to a certain extent. When the bolts and nuts or other parts rub against each other during installation and removal, this oxide film can play a certain wear-resistant role and reduce the wear on the bolt surface.

- Appearance: The black appearance makes the T-bolts look more unified and beautiful. In some occasions where there are requirements for the appearance of equipment, such as the fixing of precision instrument shells and the assembly of display equipment, blackened T-bolts can better meet visual needs.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

1.What is a T bolt used for?

A T-bolt is used for fastening components in slots or grooves, commonly in applications like industrial frames, machinery, or rail systems. Its T-shaped head provides a secure, adjustable connection.

2.Where are T-bolts used?

T-bolts are used in industrial assembly, machinery, construction, rail systems, and solar panel mounting, where secure, adjustable fastening in slots or grooves is needed.

3.How do you install a T bolt?

To install a T-bolt:

Insert the T-shaped head into a compatible slot or groove. Align the bolt and adjust its position as needed. Tighten the nut or fastener on the threaded end to secure it in place.

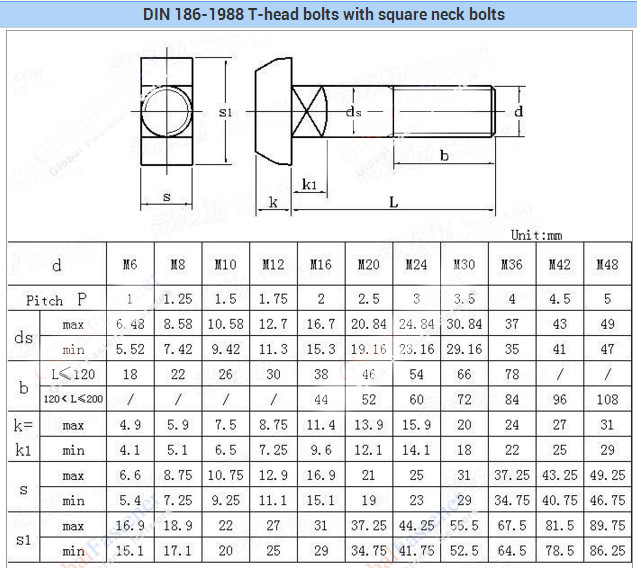

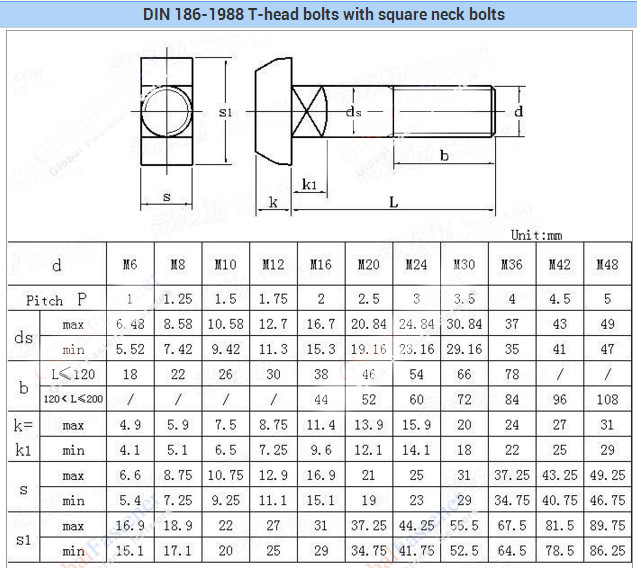

DIN261 Stainless Steel SS304 316 T Head Bolt Drawing

DIN261 Stainless Steel SS304 316 T Head Bolt Drawing