- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

DIN603

HINA

HINA2024112204

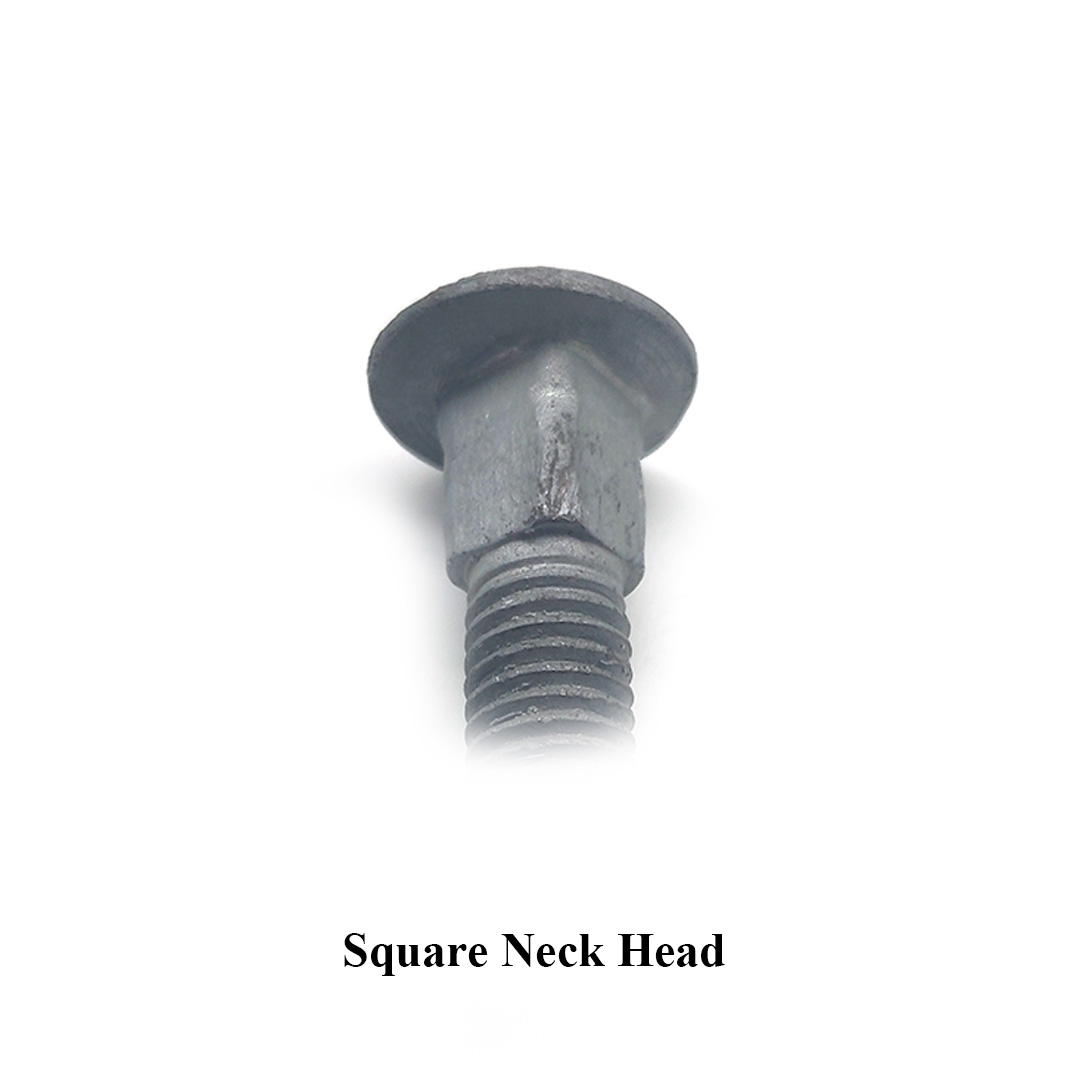

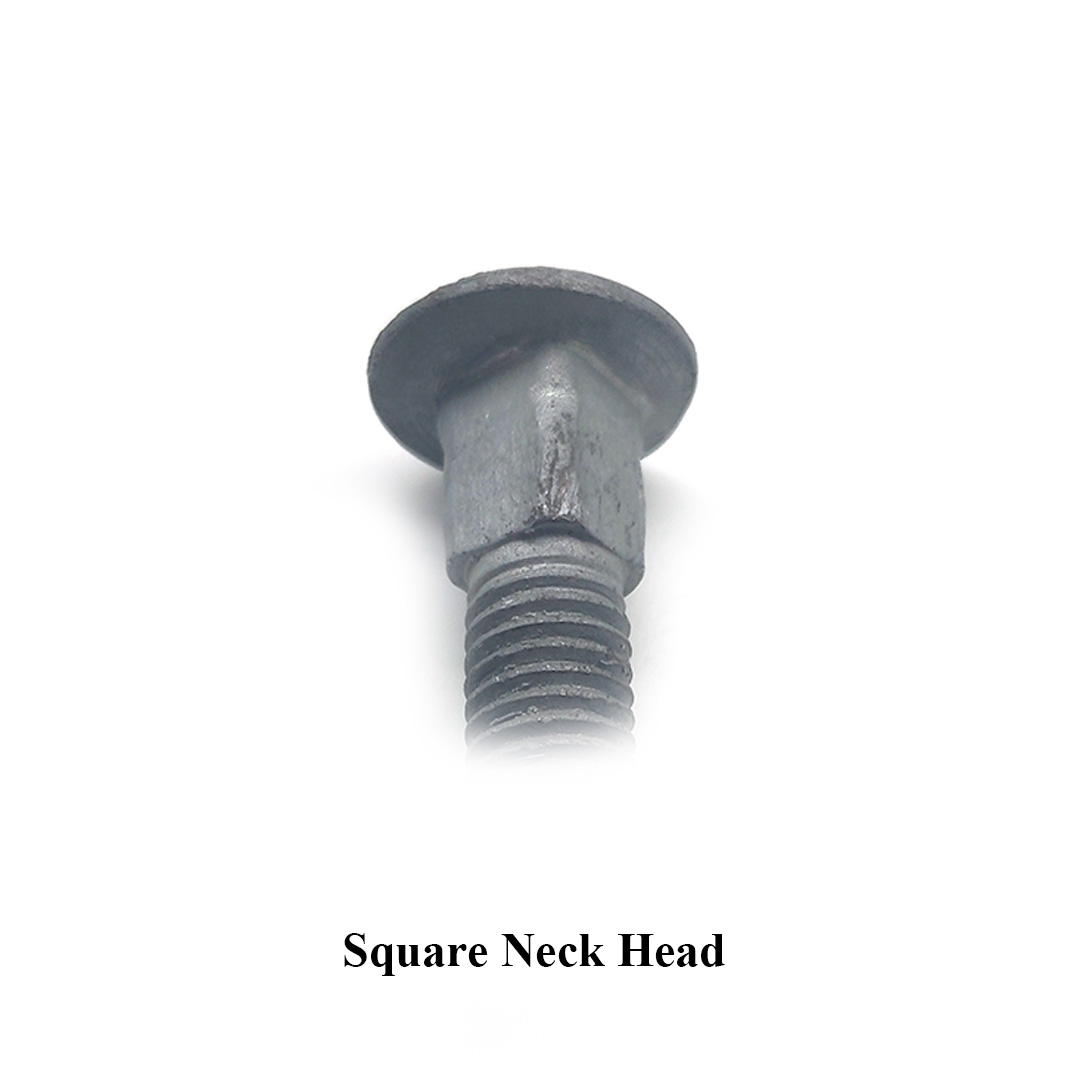

Carbon Steel A2-70 Coach Bolt Mushroom Round Head With Square Neck Bolts

Product Description

Carbon steel carriage bolt is a bolt made of carbon steel. It has a round head with a square neck below. This unique shape is to prevent the bolt from rotating with the nut during installation. The main part of the bolt is the threaded rod, which is used to cooperate with the nut to achieve the tightening function.

Product Details

Production Process

Product Application

Construction field: In the installation of solar panels on the roof of a building, carbon steel carriage bolts are used to fix the solar panel bracket to the roof structure. Its strength can ensure the stability of the solar panel when facing natural factors such as wind and rain. At the same time, in wooden structures, it can also be used to connect wooden beams, wooden columns and other components, using its square neck to embed into the wood to prevent rotation and achieve a firm connection.

Machinery manufacturing field: used for fixing the outer shell of machinery and equipment, connecting the internal frame, etc. For example, in agricultural machinery, engineering machinery and other equipment, carbon steel carriage bolts are used to tightly connect the various components together to ensure the stability and reliability of the equipment during operation.

Transportation field: Carbon steel carriage bolts are also used in the modification or simple maintenance of some vehicles. For example, it is used to fix the external devices such as the shelf and luggage rack of the vehicle, or to connect some non-critical components inside the vehicle.

Product Feature

Material properties

Strength and toughness: Carbon steel itself contains a certain amount of carbon element, which gives the carriage bolt good strength. Able to withstand a certain amount of tension and pressure, it can effectively connect components together in structures that require fast connections. At the same time, it also has a certain degree of toughness and will not break easily when it is impacted or vibrated, ensuring the safety and stability of the connection.

Ease of processing: Carbon steel materials are easy to undergo various mechanical processing, such as forging, cutting and threading. This allows carriage bolts to be easily manufactured into various specifications and shapes to meet different usage requirements. For example, carbon steel carriage bolts can be customized in different lengths and diameters to suit specific installation spaces and requirements.

Magnetism: Carbon steel is a magnetic material. In some special application scenarios, such as in some equipment that requires the use of magnetism for positioning or adsorption of components, the magnetism of carbon steel carriage bolts can be an advantage.

Ease of rusting: However, a significant disadvantage of carbon steel is its tendency to rust. Since there are not enough anti-rust elements in their composition, in humid or corrosive environments, carbon steel carriage bolts can easily react chemically with oxygen and moisture in the air to form rust, thus affecting their performance and service life.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1. How to determine the tensile strength of carbon steel carriage bolts?

Through the tensile test, the bolt is fixed on the tensile testing machine, and the axial tension is slowly applied until the bolt breaks. The maximum tension at the time of fracture is recorded, and the tensile strength is calculated based on the cross-sectional area of the bolt.

2. In which application scenarios is the shear strength of carbon steel carriage bolts a key indicator?

In the connection structure that bears lateral force, such as the connection between the solar panel bracket and the guide rail, if the shear strength is insufficient, the bolt may be sheared, resulting in structural failure.

3. What is the purpose of the heat treatment process of carbon steel carriage bolts?

Heat treatment can improve the organizational structure of the bolts. For example, quenching and tempering can improve hardness, strength and wear resistance, eliminate internal stress, make the bolt performance more stable, and meet the requirements of different use conditions.

Carbon Steel A2-70 Coach Bolt Mushroom Round Head With Square Neck Bolts

Product Description

Carbon steel carriage bolt is a bolt made of carbon steel. It has a round head with a square neck below. This unique shape is to prevent the bolt from rotating with the nut during installation. The main part of the bolt is the threaded rod, which is used to cooperate with the nut to achieve the tightening function.

Product Details

Production Process

Product Application

Construction field: In the installation of solar panels on the roof of a building, carbon steel carriage bolts are used to fix the solar panel bracket to the roof structure. Its strength can ensure the stability of the solar panel when facing natural factors such as wind and rain. At the same time, in wooden structures, it can also be used to connect wooden beams, wooden columns and other components, using its square neck to embed into the wood to prevent rotation and achieve a firm connection.

Machinery manufacturing field: used for fixing the outer shell of machinery and equipment, connecting the internal frame, etc. For example, in agricultural machinery, engineering machinery and other equipment, carbon steel carriage bolts are used to tightly connect the various components together to ensure the stability and reliability of the equipment during operation.

Transportation field: Carbon steel carriage bolts are also used in the modification or simple maintenance of some vehicles. For example, it is used to fix the external devices such as the shelf and luggage rack of the vehicle, or to connect some non-critical components inside the vehicle.

Product Feature

Material properties

Strength and toughness: Carbon steel itself contains a certain amount of carbon element, which gives the carriage bolt good strength. Able to withstand a certain amount of tension and pressure, it can effectively connect components together in structures that require fast connections. At the same time, it also has a certain degree of toughness and will not break easily when it is impacted or vibrated, ensuring the safety and stability of the connection.

Ease of processing: Carbon steel materials are easy to undergo various mechanical processing, such as forging, cutting and threading. This allows carriage bolts to be easily manufactured into various specifications and shapes to meet different usage requirements. For example, carbon steel carriage bolts can be customized in different lengths and diameters to suit specific installation spaces and requirements.

Magnetism: Carbon steel is a magnetic material. In some special application scenarios, such as in some equipment that requires the use of magnetism for positioning or adsorption of components, the magnetism of carbon steel carriage bolts can be an advantage.

Ease of rusting: However, a significant disadvantage of carbon steel is its tendency to rust. Since there are not enough anti-rust elements in their composition, in humid or corrosive environments, carbon steel carriage bolts can easily react chemically with oxygen and moisture in the air to form rust, thus affecting their performance and service life.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1. How to determine the tensile strength of carbon steel carriage bolts?

Through the tensile test, the bolt is fixed on the tensile testing machine, and the axial tension is slowly applied until the bolt breaks. The maximum tension at the time of fracture is recorded, and the tensile strength is calculated based on the cross-sectional area of the bolt.

2. In which application scenarios is the shear strength of carbon steel carriage bolts a key indicator?

In the connection structure that bears lateral force, such as the connection between the solar panel bracket and the guide rail, if the shear strength is insufficient, the bolt may be sheared, resulting in structural failure.

3. What is the purpose of the heat treatment process of carbon steel carriage bolts?

Heat treatment can improve the organizational structure of the bolts. For example, quenching and tempering can improve hardness, strength and wear resistance, eliminate internal stress, make the bolt performance more stable, and meet the requirements of different use conditions.