- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

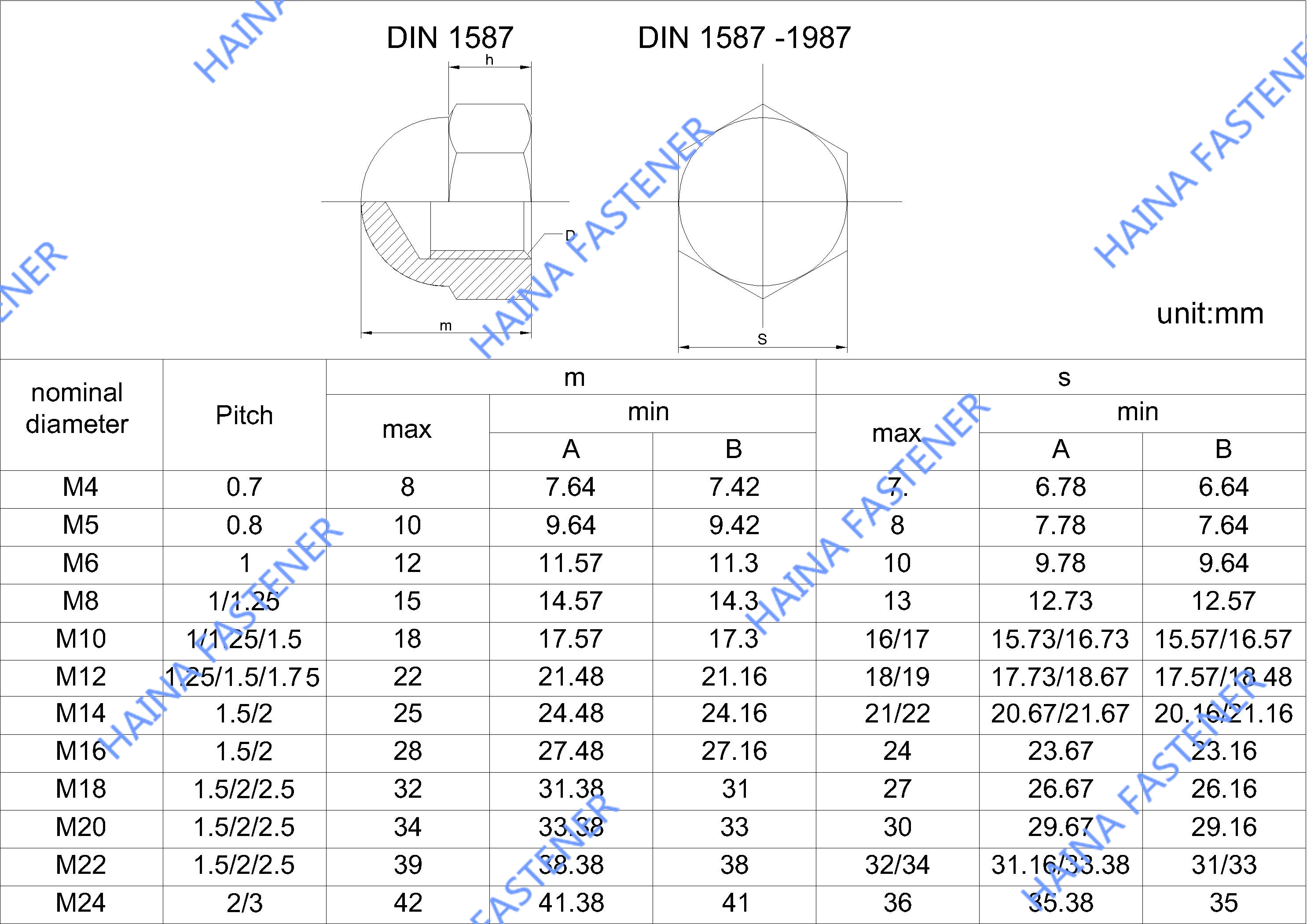

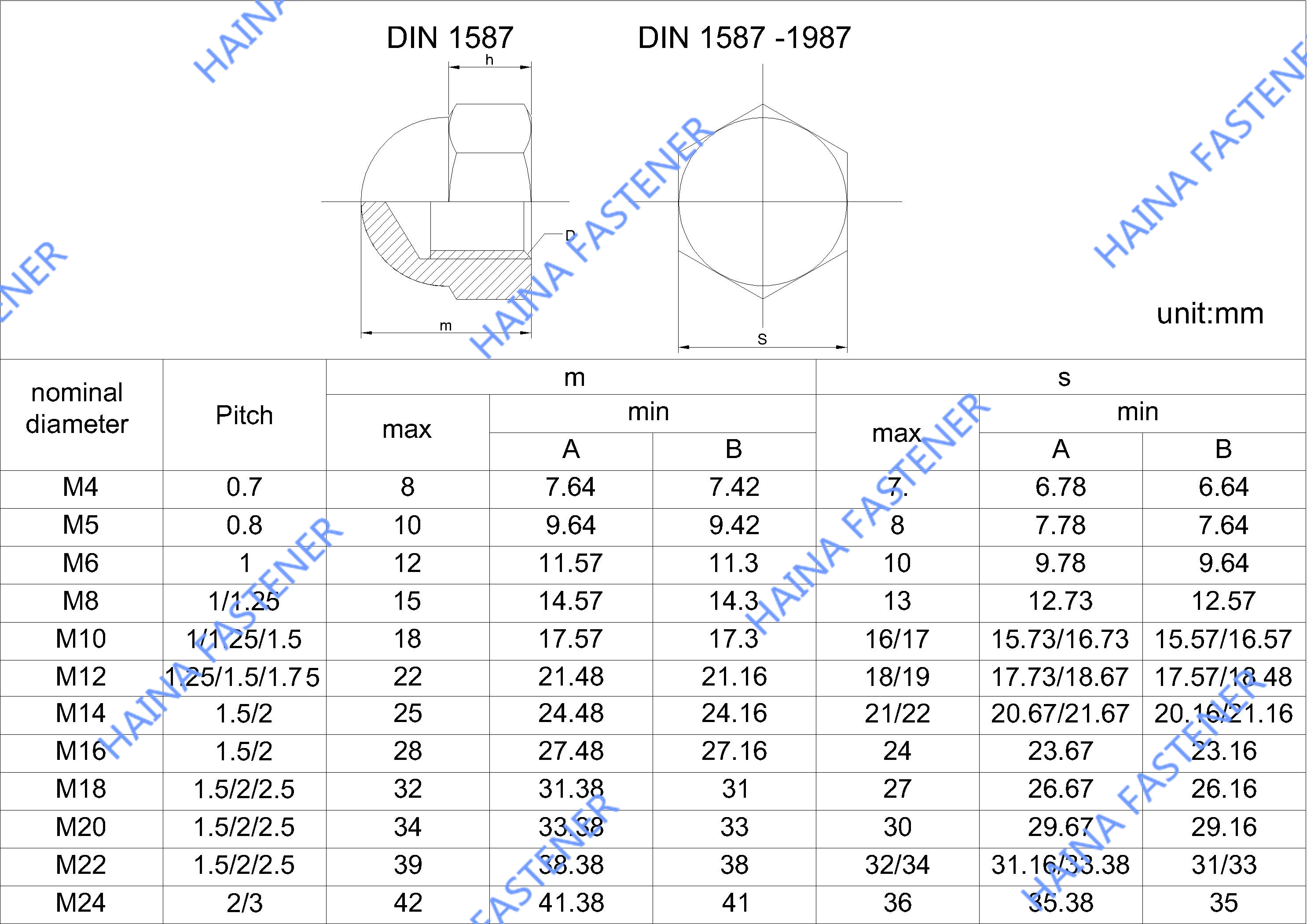

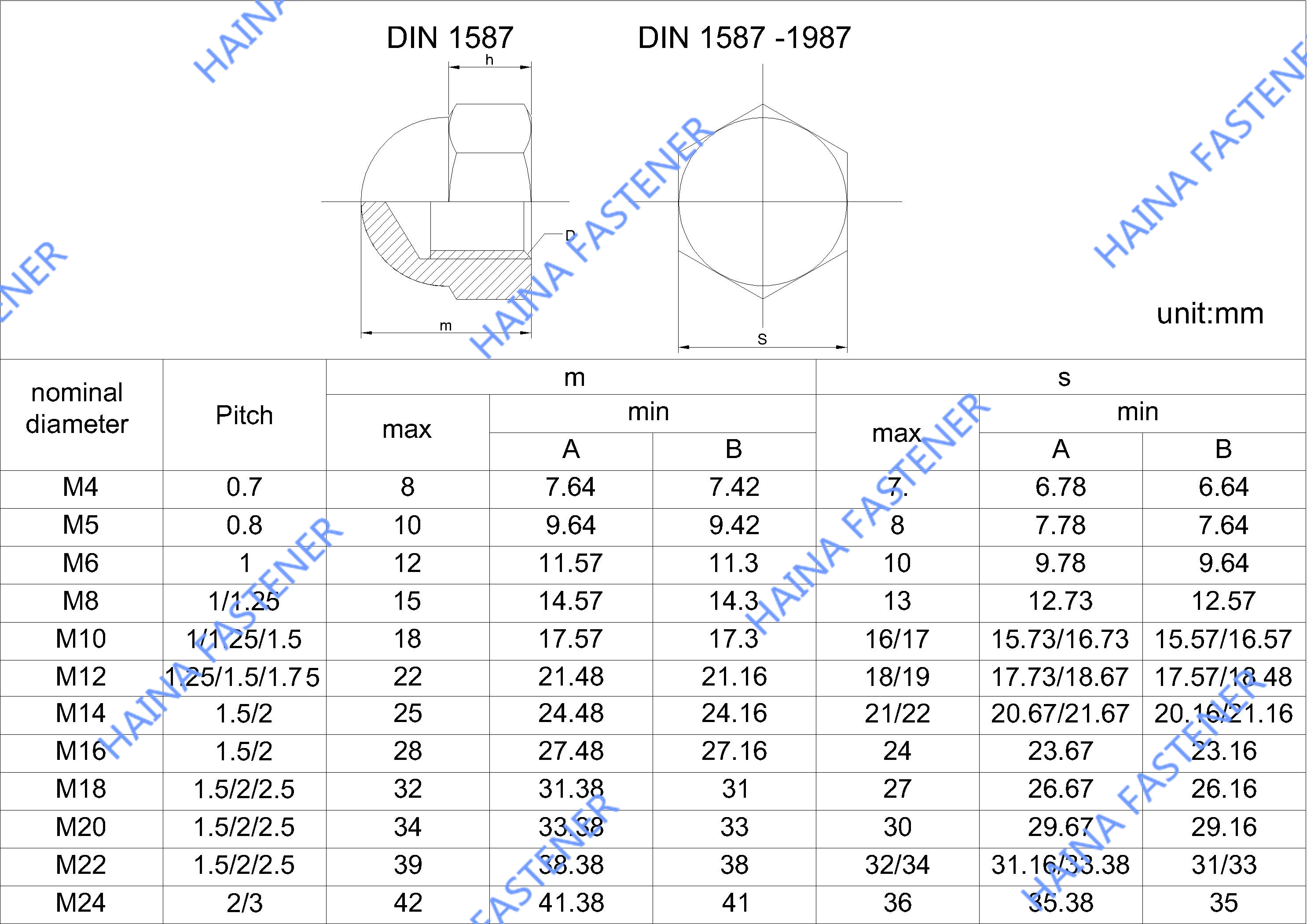

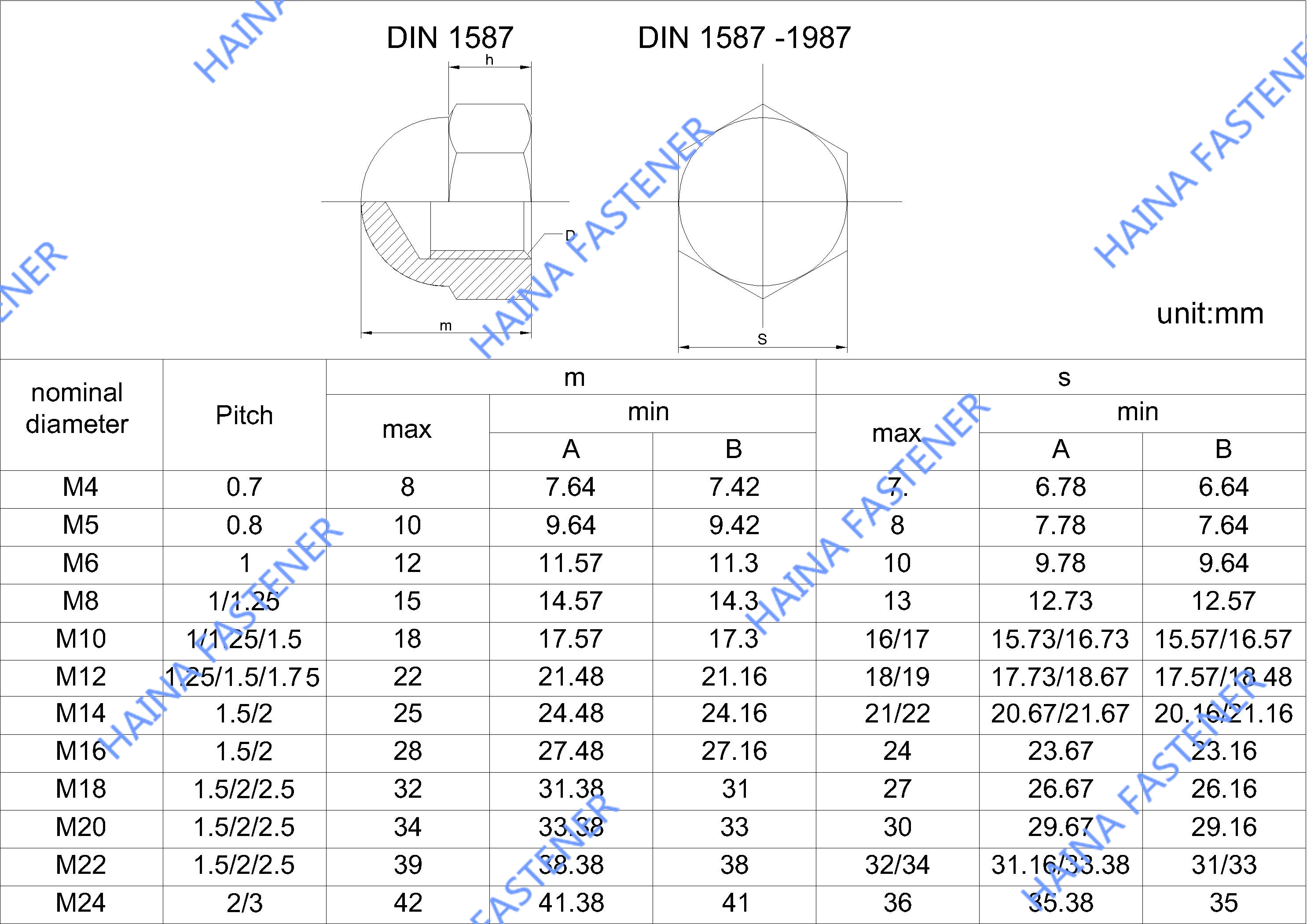

DIN1587

HNF

HNF2021011502

Plastic cap nuts are ordinary plastic nuts with a cap structure added. They are usually hexagonal in shape and have a closed cap on the top. They are used with bolts through internal threads to connect and tighten the parts together. The cap can cover the exposed part after the bolts are tightened to prevent them from being directly exposed to the outside and play a protective role.

Good insulation performance: The plastic material gives it good insulation, which can effectively avoid current conduction and signal interference. It is suitable for occasions with high requirements for electrical insulation, such as electronic equipment and communication engineering.

Strong corrosion resistance: It has good tolerance to chemical substances such as acids, alkalis, and salts, and can maintain stable performance in humid and chemically corrosive environments. It is not easy to be damaged. It has obvious advantages in some chemical equipment and electroplating industries.

Light weight: Compared with metal cap nuts, plastic cap nuts are lighter. In equipment or products with weight requirements, they help reduce the overall weight, such as aerospace and small electronic products.

Low cost: The cost of plastic raw materials and manufacturing costs are usually lower than metals. When the strength requirements are not particularly high and a large number of nuts are needed, the cost can be effectively controlled.

It has certain shock absorption: plastic materials have certain elasticity and flexibility. When subjected to vibration or impact, they can play a certain shock absorption and buffering role, reducing wear and looseness between parts.

Diverse appearance: By adding different pigments or performing surface treatment, various colors and appearance effects can be made to meet the aesthetic needs of different scenes, and special shapes and sizes can be customized according to needs.

Electronic and electrical fields: used for the internal assembly of electronic products such as computers, mobile phones, tablets, and televisions, fixing circuit boards, parts, etc., and its insulation can prevent circuit short circuits and signal interference.

Household items: Furniture assembly, such as the connection parts of wardrobes, desks, chairs, etc.; it is also used in the connection and fixation of some plastic pipes, as well as the installation of plastic lamps.

Toy industry: Assembly and fixation of toys, especially some plastic toys, plastic cap nuts are light in weight, low in cost, and can also ensure a certain tightening effect.

Medical equipment: Connection and fixation of internal components of some medical instruments and meters that require insulation and corrosion resistance.

Outdoor facilities: such as plastic awnings, outdoor furniture, and assembly and fixation of small plastic products, which can resist outdoor moisture and general corrosion environments.

Automobile interior: Fixing some plastic parts and decorative parts inside the car, using its light weight, insulation and certain shock absorption to improve the quality and safety of the car interior.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

What materials are commonly used to make cap nuts?

Cap nuts are commonly made of materials such as carbon steel, stainless steel, and plastic. Carbon steel ones offer high strength at a relatively low cost. Stainless - steel cap nuts are highly corrosion - resistant, suitable for harsh environments. Plastic cap nuts are lightweight, have good insulation properties, and are often used in electronic products.

How do I choose the right cap nut for my application?

First, consider the material based on the working environment. For example, choose stainless - steel cap nuts in corrosive environments. Then, match the size of the cap nut with the bolt it will be used with. Also, think about the required torque and load - bearing capacity.

Plastic cap nuts are ordinary plastic nuts with a cap structure added. They are usually hexagonal in shape and have a closed cap on the top. They are used with bolts through internal threads to connect and tighten the parts together. The cap can cover the exposed part after the bolts are tightened to prevent them from being directly exposed to the outside and play a protective role.

Good insulation performance: The plastic material gives it good insulation, which can effectively avoid current conduction and signal interference. It is suitable for occasions with high requirements for electrical insulation, such as electronic equipment and communication engineering.

Strong corrosion resistance: It has good tolerance to chemical substances such as acids, alkalis, and salts, and can maintain stable performance in humid and chemically corrosive environments. It is not easy to be damaged. It has obvious advantages in some chemical equipment and electroplating industries.

Light weight: Compared with metal cap nuts, plastic cap nuts are lighter. In equipment or products with weight requirements, they help reduce the overall weight, such as aerospace and small electronic products.

Low cost: The cost of plastic raw materials and manufacturing costs are usually lower than metals. When the strength requirements are not particularly high and a large number of nuts are needed, the cost can be effectively controlled.

It has certain shock absorption: plastic materials have certain elasticity and flexibility. When subjected to vibration or impact, they can play a certain shock absorption and buffering role, reducing wear and looseness between parts.

Diverse appearance: By adding different pigments or performing surface treatment, various colors and appearance effects can be made to meet the aesthetic needs of different scenes, and special shapes and sizes can be customized according to needs.

Electronic and electrical fields: used for the internal assembly of electronic products such as computers, mobile phones, tablets, and televisions, fixing circuit boards, parts, etc., and its insulation can prevent circuit short circuits and signal interference.

Household items: Furniture assembly, such as the connection parts of wardrobes, desks, chairs, etc.; it is also used in the connection and fixation of some plastic pipes, as well as the installation of plastic lamps.

Toy industry: Assembly and fixation of toys, especially some plastic toys, plastic cap nuts are light in weight, low in cost, and can also ensure a certain tightening effect.

Medical equipment: Connection and fixation of internal components of some medical instruments and meters that require insulation and corrosion resistance.

Outdoor facilities: such as plastic awnings, outdoor furniture, and assembly and fixation of small plastic products, which can resist outdoor moisture and general corrosion environments.

Automobile interior: Fixing some plastic parts and decorative parts inside the car, using its light weight, insulation and certain shock absorption to improve the quality and safety of the car interior.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

What materials are commonly used to make cap nuts?

Cap nuts are commonly made of materials such as carbon steel, stainless steel, and plastic. Carbon steel ones offer high strength at a relatively low cost. Stainless - steel cap nuts are highly corrosion - resistant, suitable for harsh environments. Plastic cap nuts are lightweight, have good insulation properties, and are often used in electronic products.

How do I choose the right cap nut for my application?

First, consider the material based on the working environment. For example, choose stainless - steel cap nuts in corrosive environments. Then, match the size of the cap nut with the bolt it will be used with. Also, think about the required torque and load - bearing capacity.