- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

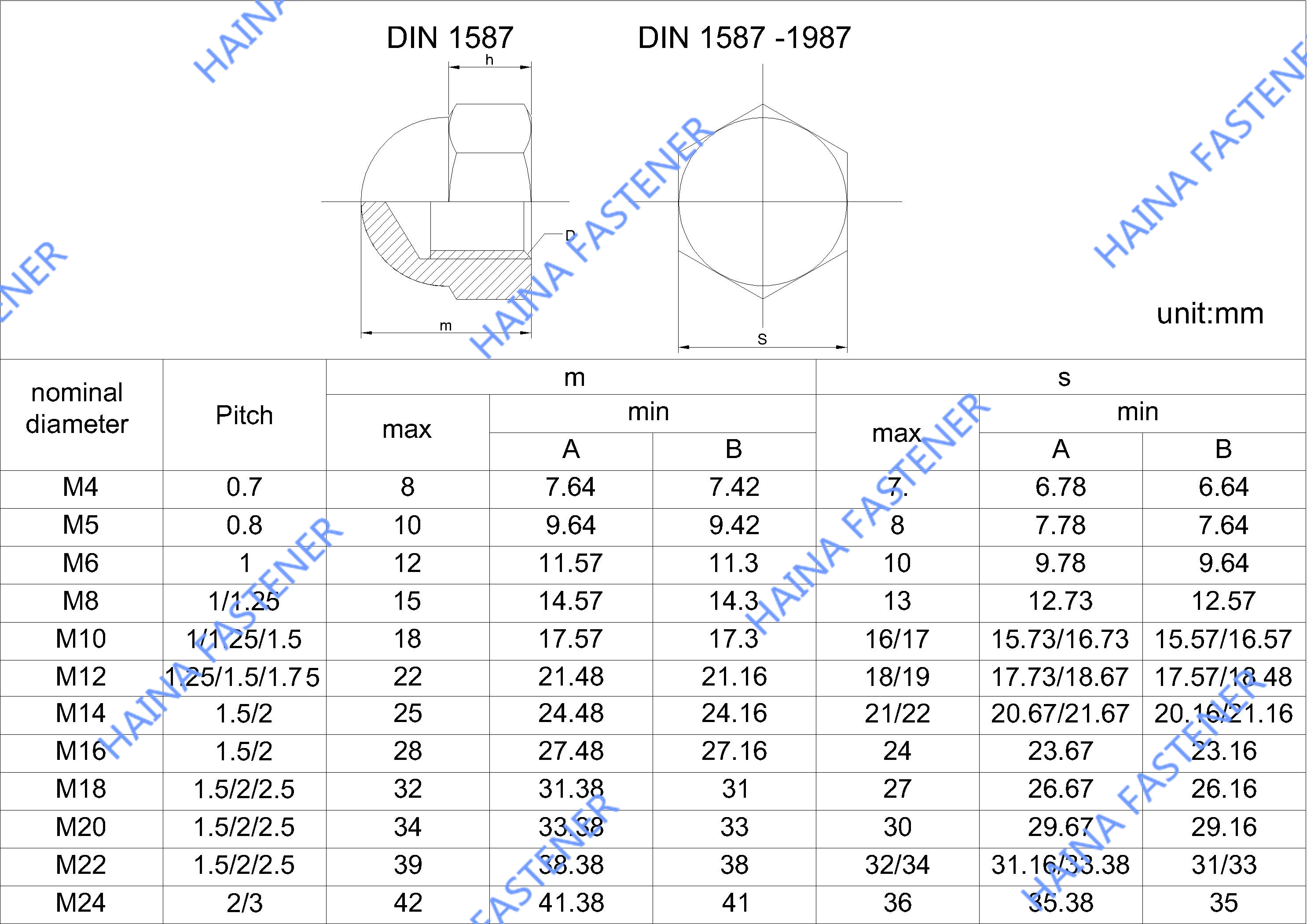

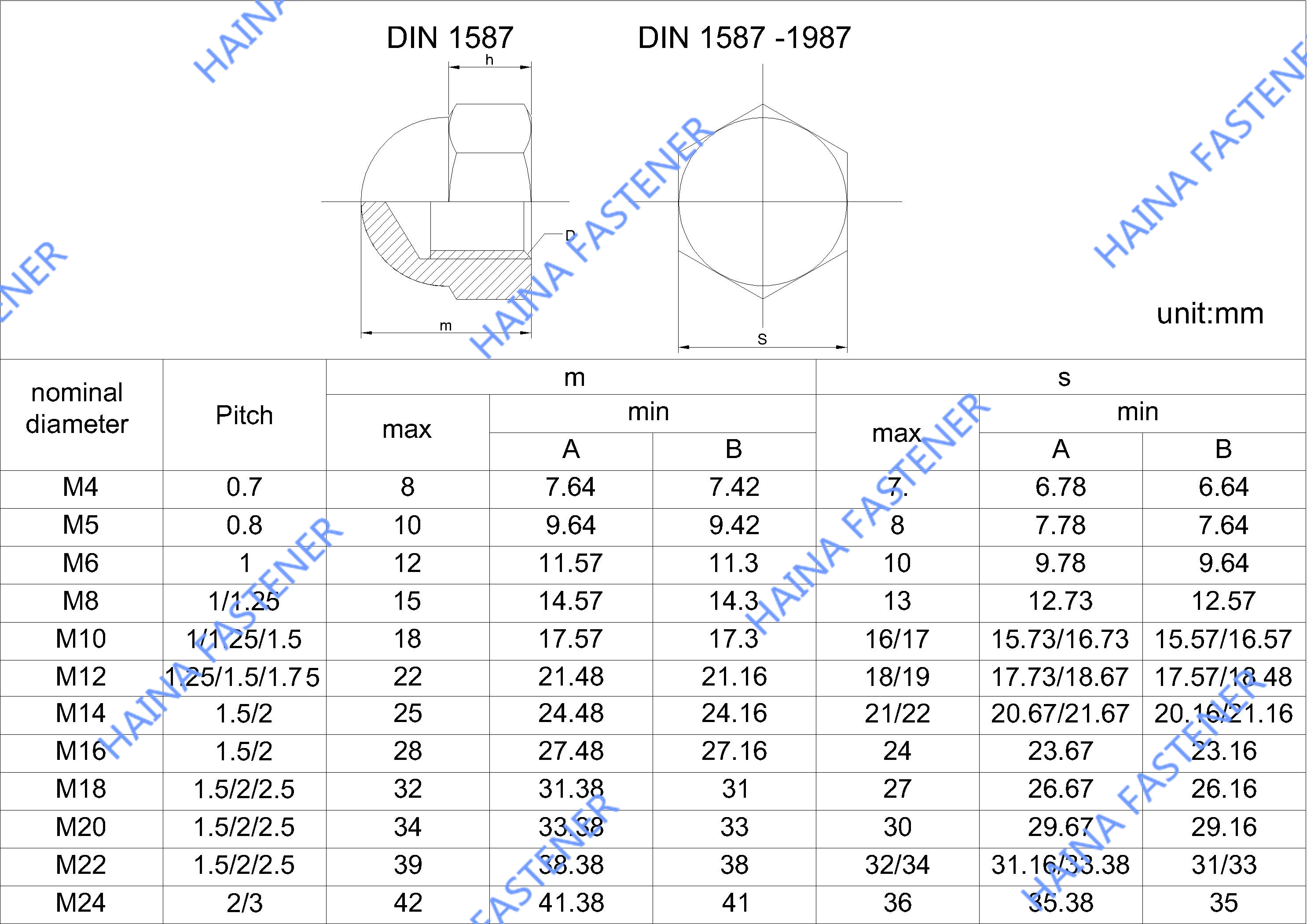

DIN1587

HNF

HINA2025021402

Nylon cap nut is a nut with a cover made of nylon as the main material. It is usually hexagonal and has a closed cover on the top. It is used in conjunction with bolts through internal threads. After the parts are connected and tightened, the cover can cover the exposed part of the bolt to protect and seal it.

Advantages

Good insulation performance: Nylon is an insulating material. Nylon cap nut can effectively prevent the passage of current, avoid circuit short circuits and electrical accidents, and has obvious application advantages in the field of electrical and electronic equipment.

Excellent corrosion resistance: It has good tolerance to most acids, alkalis, salts and organic solvents, is not easily corroded, can maintain stable performance in harsh chemical environments, and prolongs service life.

Good self-lubrication: Nylon material has self-lubricating properties. When used with bolts, it has a low friction coefficient, is easy to install and disassemble, and can also reduce wear on the bolt surface.

Shock reduction and noise reduction: Nylon has a certain elasticity and flexibility. When subjected to vibration or impact, it can absorb and buffer energy, play a role in shock reduction and noise reduction, and can reduce looseness and wear between components caused by vibration.

Light weight: Compared with metal cap nuts, nylon cap nuts are significantly lighter. In equipment or products with strict weight requirements, they help reduce the overall weight and improve the performance and efficiency of the equipment.

Low cost: The cost of nylon materials is relatively low, and the manufacturing process is simple, which makes the overall cost of nylon cap nuts not high. On the premise of meeting the use requirements, it can save costs for users.

Electronic and electrical industry: Widely used in the assembly of electronic equipment, such as computers, mobile phones, televisions, etc., for fixing circuit boards, electronic components, etc., and its insulation performance can ensure the safety and stable operation of the circuit.

Automobile manufacturing field: It can be used to fix automotive interior parts, such as dashboards, seats, door interiors, etc., using its shock absorption, noise reduction and light weight characteristics to improve the comfort and overall performance of the car; it can also be used to connect some components in automotive electronic systems.

Aerospace industry: Due to the advantage of light weight, in aerospace equipment, it is used to connect some weight-sensitive components, such as aircraft interiors, electronic equipment installation, etc., which helps to reduce the weight of aircraft and improve fuel efficiency and flight performance.

Chemical equipment: In chemical production equipment, it is used to connect and fix some parts that are not pressure-bearing or do not require particularly high strength, but require good corrosion resistance, such as the connection of plastic pipes, the installation of chemical instruments, etc.

Household items: In furniture manufacturing, it is used to connect and fix some plastic or wooden parts, such as the assembly of wardrobes and cabinets; it can also be used for the internal fixation of some small household appliances.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

How do I choose the right cap nut for my application?

First, consider the material based on the working environment. For example, choose stainless - steel cap nuts in corrosive environments. Then, match the size of the cap nut with the bolt it will be used with. Also, think about the required torque and load - bearing capacity.

Where are cap nuts mainly used?

They are widely used in various industries. In the automotive industry, they are used to fasten engine components and chassis parts. In construction, for steel structure connections. In electronics, plastic cap nuts are used to fix circuit boards and components due to their insulation properties.

Nylon cap nut is a nut with a cover made of nylon as the main material. It is usually hexagonal and has a closed cover on the top. It is used in conjunction with bolts through internal threads. After the parts are connected and tightened, the cover can cover the exposed part of the bolt to protect and seal it.

Advantages

Good insulation performance: Nylon is an insulating material. Nylon cap nut can effectively prevent the passage of current, avoid circuit short circuits and electrical accidents, and has obvious application advantages in the field of electrical and electronic equipment.

Excellent corrosion resistance: It has good tolerance to most acids, alkalis, salts and organic solvents, is not easily corroded, can maintain stable performance in harsh chemical environments, and prolongs service life.

Good self-lubrication: Nylon material has self-lubricating properties. When used with bolts, it has a low friction coefficient, is easy to install and disassemble, and can also reduce wear on the bolt surface.

Shock reduction and noise reduction: Nylon has a certain elasticity and flexibility. When subjected to vibration or impact, it can absorb and buffer energy, play a role in shock reduction and noise reduction, and can reduce looseness and wear between components caused by vibration.

Light weight: Compared with metal cap nuts, nylon cap nuts are significantly lighter. In equipment or products with strict weight requirements, they help reduce the overall weight and improve the performance and efficiency of the equipment.

Low cost: The cost of nylon materials is relatively low, and the manufacturing process is simple, which makes the overall cost of nylon cap nuts not high. On the premise of meeting the use requirements, it can save costs for users.

Electronic and electrical industry: Widely used in the assembly of electronic equipment, such as computers, mobile phones, televisions, etc., for fixing circuit boards, electronic components, etc., and its insulation performance can ensure the safety and stable operation of the circuit.

Automobile manufacturing field: It can be used to fix automotive interior parts, such as dashboards, seats, door interiors, etc., using its shock absorption, noise reduction and light weight characteristics to improve the comfort and overall performance of the car; it can also be used to connect some components in automotive electronic systems.

Aerospace industry: Due to the advantage of light weight, in aerospace equipment, it is used to connect some weight-sensitive components, such as aircraft interiors, electronic equipment installation, etc., which helps to reduce the weight of aircraft and improve fuel efficiency and flight performance.

Chemical equipment: In chemical production equipment, it is used to connect and fix some parts that are not pressure-bearing or do not require particularly high strength, but require good corrosion resistance, such as the connection of plastic pipes, the installation of chemical instruments, etc.

Household items: In furniture manufacturing, it is used to connect and fix some plastic or wooden parts, such as the assembly of wardrobes and cabinets; it can also be used for the internal fixation of some small household appliances.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

How do I choose the right cap nut for my application?

First, consider the material based on the working environment. For example, choose stainless - steel cap nuts in corrosive environments. Then, match the size of the cap nut with the bolt it will be used with. Also, think about the required torque and load - bearing capacity.

Where are cap nuts mainly used?

They are widely used in various industries. In the automotive industry, they are used to fasten engine components and chassis parts. In construction, for steel structure connections. In electronics, plastic cap nuts are used to fix circuit boards and components due to their insulation properties.