- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

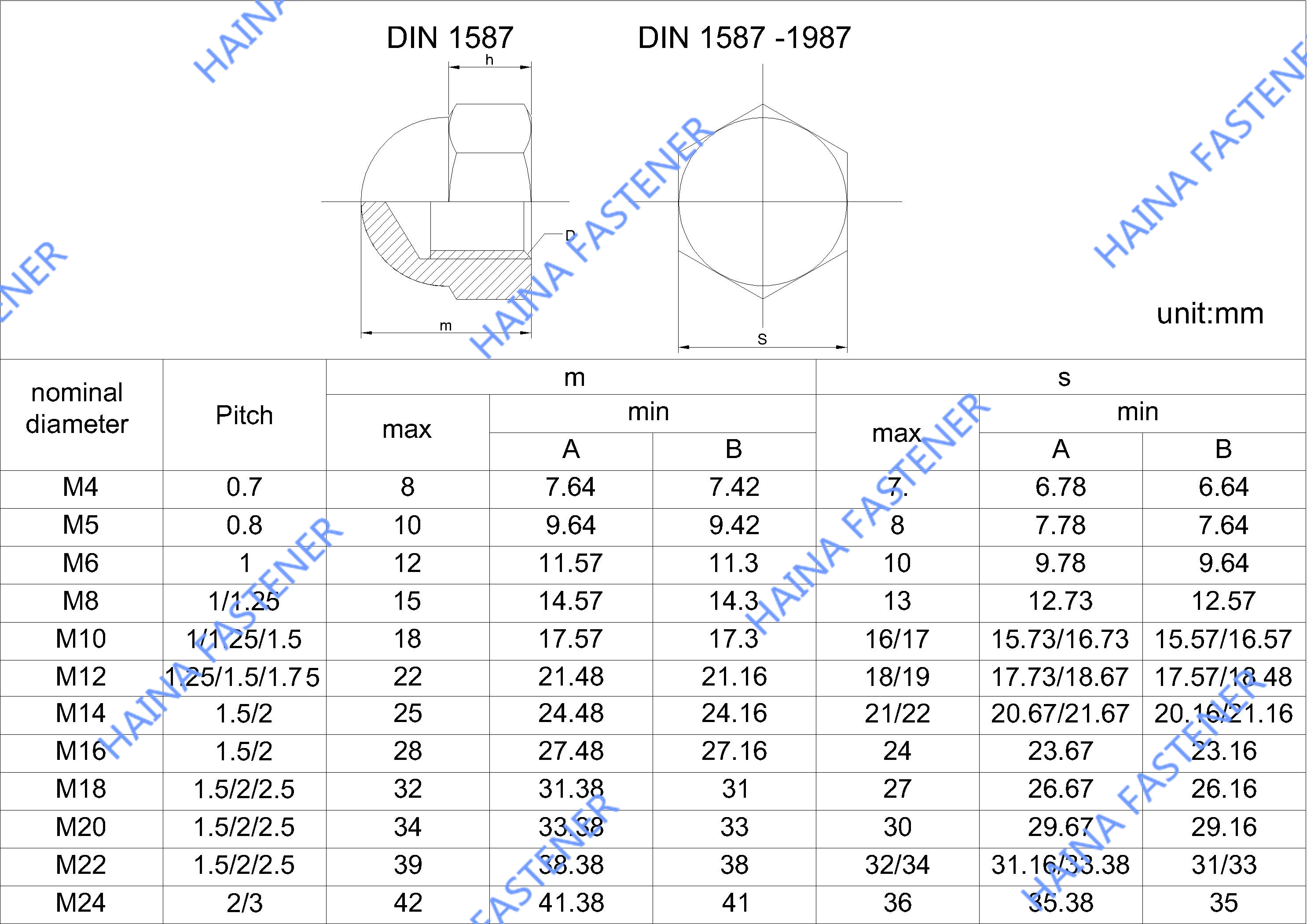

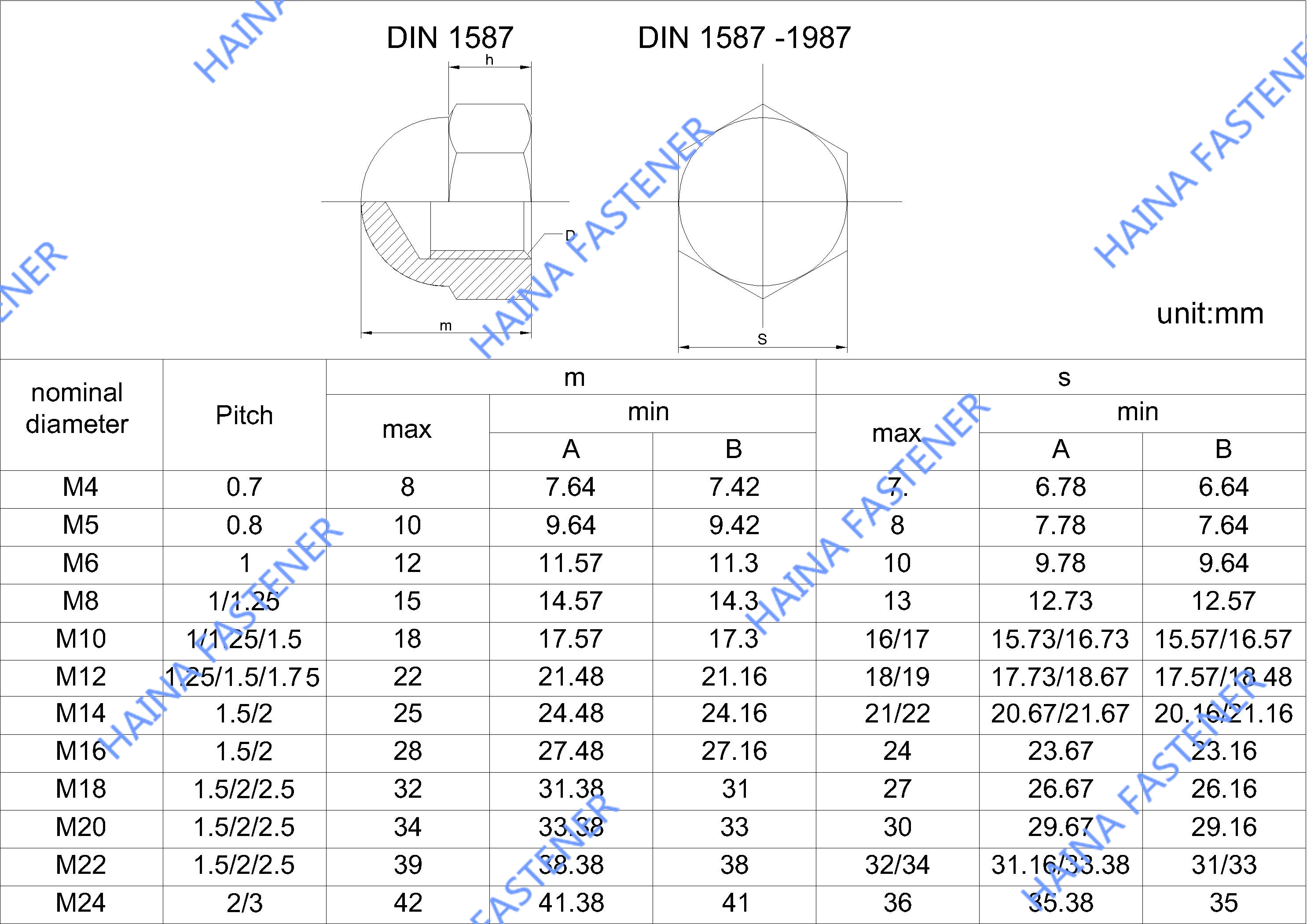

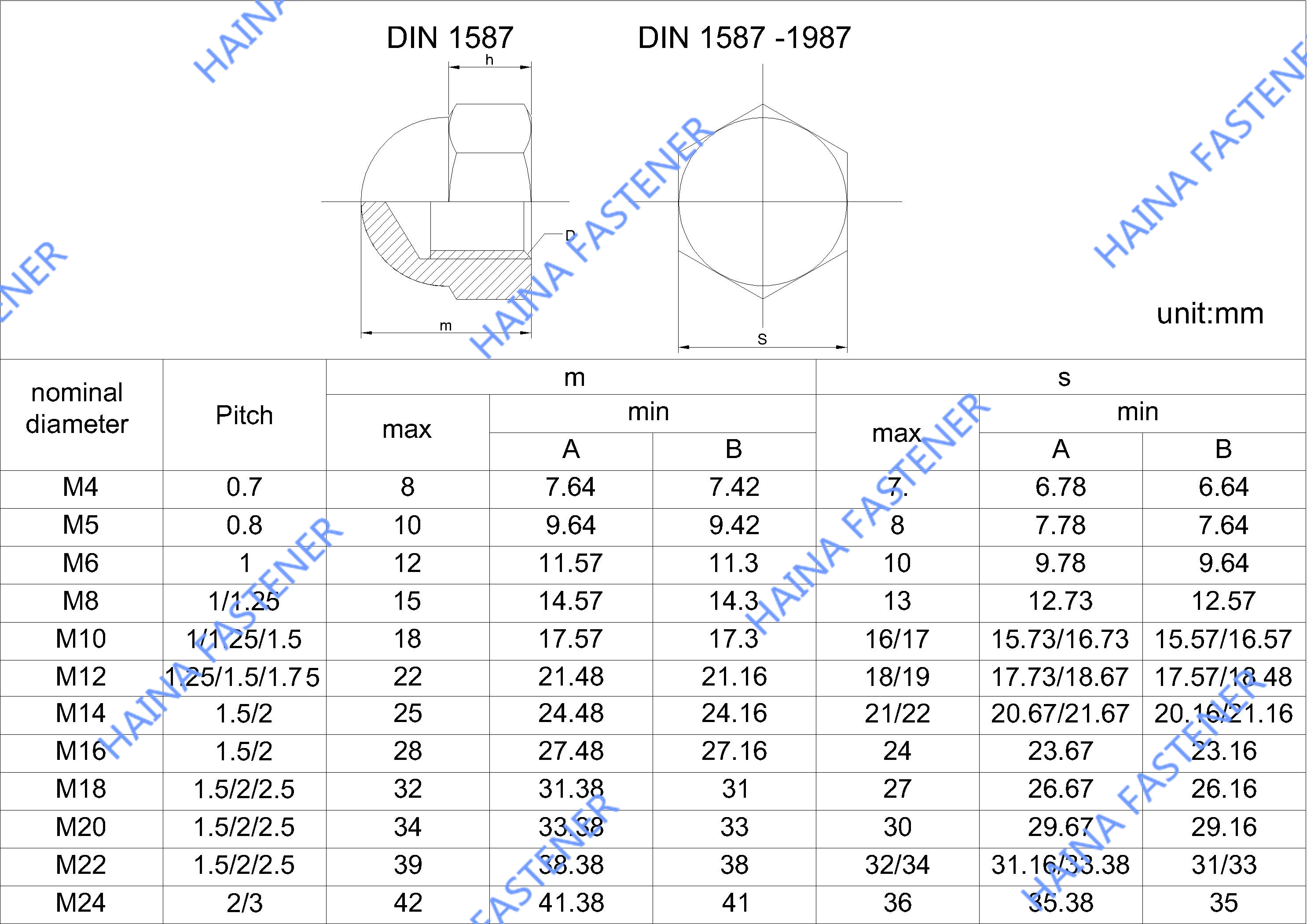

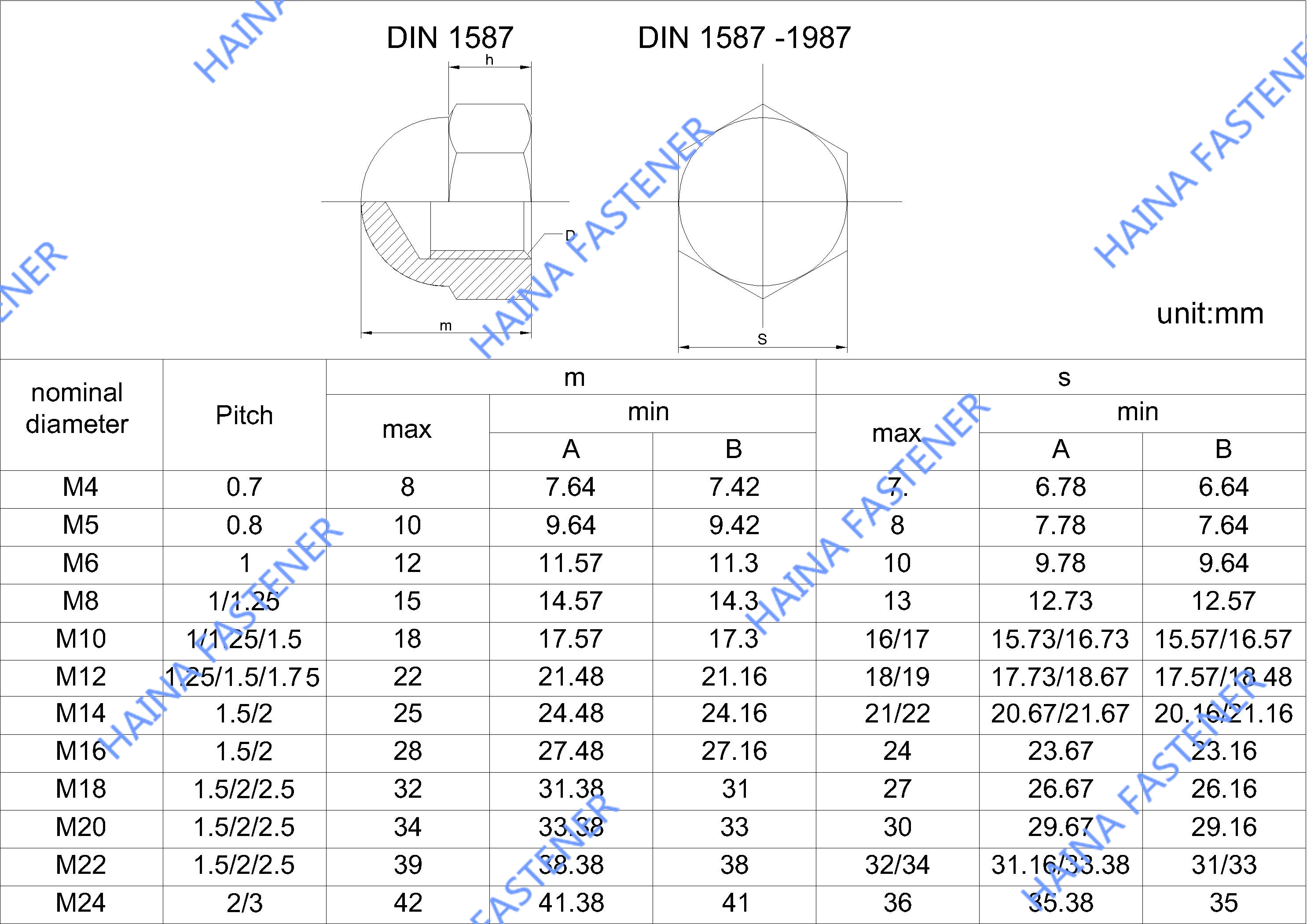

DIN1587

HNF

HNF2021011503

Carbon steel cap nuts are hexagonal nuts with a cap structure added to them. They are hexagonal in shape and have a closed cap on the top. They are used with bolts through internal threads to connect and tighten the parts together. The cap can cover the exposed part after the bolts are tightened to prevent them from being directly exposed.

Cost advantage: Compared with cap nuts made of materials such as stainless steel, carbon steel has a lower cost and can effectively control costs in scenarios where corrosion resistance is not particularly high.

High strength: Carbon steel has high strength and hardness, can withstand large tension and pressure, can ensure the stability of the connection under various mechanical forces, and is suitable for occasions with high requirements for fastening strength.

Good processing performance: Carbon steel has good plasticity and processability, and is easy to process by forging, stamping, cutting and other processing techniques. It can easily manufacture cap nuts of various specifications and precision requirements to meet the needs of different application scenarios.

Various surface treatments: Through surface treatment processes such as galvanizing, nickel plating, chrome plating and Dacromet, its anti-corrosion ability can be effectively improved, its performance can be improved, and it can adapt to different environments to a certain extent.

Basic protective performance: Its cover structure can block some dust, debris and moisture, play a certain protective role on the bolt connection parts, reduce the impact of external factors on the connection parts, and extend the service life of the connection parts.

Mechanical manufacturing: In the manufacture of various general mechanical equipment, such as machine tools, fans, compressors, etc., it is used to fix gears, shafts, bearing seats and other parts to ensure that the relative positions of various parts of the equipment are fixed during operation and withstand various forces generated during the operation of the equipment.

Automobile industry: Commonly used for the connection and fastening of the chassis, frame, engine and other parts of the car, such as fixing the suspension system parts of the car, connecting the transmission shaft, etc., to withstand vibration and impact during the driving process of the vehicle, and ensure the safety and stability of the car.

Construction field: It is more common in the connection of building steel structures, such as for connecting structural parts such as steel beams and steel columns; it can also be used for the installation and fixation of construction equipment, such as the connection between construction elevators, material hoists and other equipment and building structures.

General industrial equipment: In various equipment in the chemical, electric power, textile and other industries, it is used for the assembly and fixation of equipment, such as the bracket fixation of chemical pipelines, the installation and fixation of motors, and the connection of parts of textile machinery.

Agricultural machinery: In agricultural machinery and equipment such as tractors and harvesters, it is used to connect and fasten various components, such as the connection between the engine and the frame, the fixation of transmission components, etc., to adapt to various working conditions in the agricultural production environment.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

Where are cap nuts mainly used?

They are widely used in various industries. In the automotive industry, they are used to fasten engine components and chassis parts. In construction, for steel structure connections. In electronics, plastic cap nuts are used to fix circuit boards and components due to their insulation properties.

What are the advantages of cap nuts compared to ordinary nuts?

Cap nuts have a cover that can protect the exposed part of the bolt from moisture, dust, and corrosion, which extends the service life of the connection. They also often have better anti - loosening performance due to their design, especially in vibrating environments.

Carbon steel cap nuts are hexagonal nuts with a cap structure added to them. They are hexagonal in shape and have a closed cap on the top. They are used with bolts through internal threads to connect and tighten the parts together. The cap can cover the exposed part after the bolts are tightened to prevent them from being directly exposed.

Cost advantage: Compared with cap nuts made of materials such as stainless steel, carbon steel has a lower cost and can effectively control costs in scenarios where corrosion resistance is not particularly high.

High strength: Carbon steel has high strength and hardness, can withstand large tension and pressure, can ensure the stability of the connection under various mechanical forces, and is suitable for occasions with high requirements for fastening strength.

Good processing performance: Carbon steel has good plasticity and processability, and is easy to process by forging, stamping, cutting and other processing techniques. It can easily manufacture cap nuts of various specifications and precision requirements to meet the needs of different application scenarios.

Various surface treatments: Through surface treatment processes such as galvanizing, nickel plating, chrome plating and Dacromet, its anti-corrosion ability can be effectively improved, its performance can be improved, and it can adapt to different environments to a certain extent.

Basic protective performance: Its cover structure can block some dust, debris and moisture, play a certain protective role on the bolt connection parts, reduce the impact of external factors on the connection parts, and extend the service life of the connection parts.

Mechanical manufacturing: In the manufacture of various general mechanical equipment, such as machine tools, fans, compressors, etc., it is used to fix gears, shafts, bearing seats and other parts to ensure that the relative positions of various parts of the equipment are fixed during operation and withstand various forces generated during the operation of the equipment.

Automobile industry: Commonly used for the connection and fastening of the chassis, frame, engine and other parts of the car, such as fixing the suspension system parts of the car, connecting the transmission shaft, etc., to withstand vibration and impact during the driving process of the vehicle, and ensure the safety and stability of the car.

Construction field: It is more common in the connection of building steel structures, such as for connecting structural parts such as steel beams and steel columns; it can also be used for the installation and fixation of construction equipment, such as the connection between construction elevators, material hoists and other equipment and building structures.

General industrial equipment: In various equipment in the chemical, electric power, textile and other industries, it is used for the assembly and fixation of equipment, such as the bracket fixation of chemical pipelines, the installation and fixation of motors, and the connection of parts of textile machinery.

Agricultural machinery: In agricultural machinery and equipment such as tractors and harvesters, it is used to connect and fasten various components, such as the connection between the engine and the frame, the fixation of transmission components, etc., to adapt to various working conditions in the agricultural production environment.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

Where are cap nuts mainly used?

They are widely used in various industries. In the automotive industry, they are used to fasten engine components and chassis parts. In construction, for steel structure connections. In electronics, plastic cap nuts are used to fix circuit boards and components due to their insulation properties.

What are the advantages of cap nuts compared to ordinary nuts?

Cap nuts have a cover that can protect the exposed part of the bolt from moisture, dust, and corrosion, which extends the service life of the connection. They also often have better anti - loosening performance due to their design, especially in vibrating environments.