- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HINA

HINA2024121205

Bi metal screws are screws made of two different metals, which combine the characteristics of the two metals to provide excellent performance and durability. They are usually used in scenarios that require corrosion resistance, high strength or special conductivity.

Bi-metal screw, materials are SS304+SS410, SS316+SS410, SS304+SCM435, SS316+SCM435, anti-corrosion performance can reach 1000 hours, self-tapping composite nails are mainly used for the installation of photovoltaic support, can punch 0.4-1.00mm iron plate, self-drilling composite nails, Can be penetrated 1-6mm iron plate.

Construction industry: In construction, it is widely used for the installation and fixation of steel structures, color steel plates, roof panels, etc. For example, when the color steel plate is fixed on the light steel keel, the self-drilling and self-tapping performance of bimetallic screws can quickly complete the installation, and its corrosion resistance can ensure the reliability of the connection in long-term use.

Manufacturing industry: Commonly used in the assembly of mechanical equipment, the connection of the body and engine in automobile manufacturing, etc. On the automobile production line, bimetallic screws can firmly connect parts of different materials together, such as connecting plastic panels to metal body frames. Its good comprehensive performance can adapt to complex working conditions and frequent vibrations.

Electronic and electrical industry: In electronic equipment, it can be used for the installation of circuit boards and the grounding connection of various electrical equipment. Due to its good conductivity and corrosion resistance, it can ensure reliable electrical connection between electronic components and prevent electrical failures caused by screw corrosion.

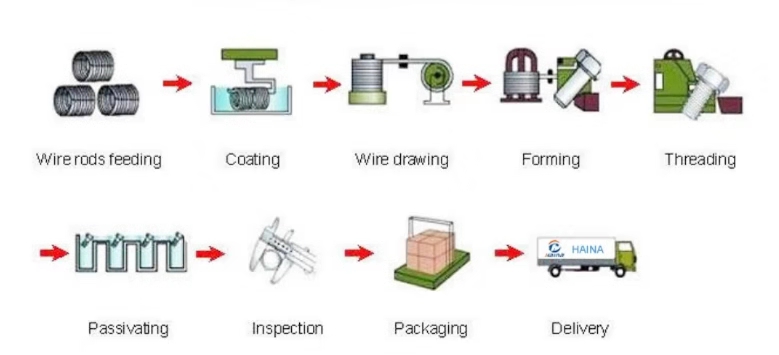

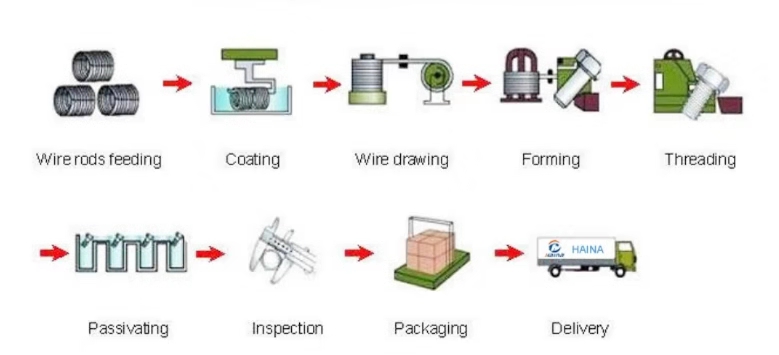

Jiaxing Haina Fastener co. Ltd was established in 2010, located in the hometown of fasteners jiaxing city. For many years of export experience, our products has been best-selling in Europe, the United States, the Middle East and Southeast Asia. The products are manufactured by more functions machine, which is brought in domestic and foreign well-known enterprises. The products made are fully compatible with the international standards, well received by domestic and foreign customers.

What is the difference between galvanized screws and regular screws?

Galvanized screws are coated with a layer of zinc to resist corrosion, making them ideal for outdoor or wet environments. Regular screws lack this coating, making them more prone to rust and unsuitable for harsh conditions.

What is a bi-metal screw?

A bi-metal screw is a fastener made from two different metals, combining the strength of one metal (like steel) with the corrosion resistance or special properties of another (like stainless steel). This design ensures durability, strength, and adaptability for use in harsh environments like marine, construction, or chemical industries.

What screws are best for drilling into metal?

Self-drilling screws (Tek screws) are best for drilling into metal, as they have a built-in drill bit tip for effortless penetration. Choose screws made of hardened or stainless steel for durability and corrosion resistance.

Bi metal screws are screws made of two different metals, which combine the characteristics of the two metals to provide excellent performance and durability. They are usually used in scenarios that require corrosion resistance, high strength or special conductivity.

Bi-metal screw, materials are SS304+SS410, SS316+SS410, SS304+SCM435, SS316+SCM435, anti-corrosion performance can reach 1000 hours, self-tapping composite nails are mainly used for the installation of photovoltaic support, can punch 0.4-1.00mm iron plate, self-drilling composite nails, Can be penetrated 1-6mm iron plate.

Construction industry: In construction, it is widely used for the installation and fixation of steel structures, color steel plates, roof panels, etc. For example, when the color steel plate is fixed on the light steel keel, the self-drilling and self-tapping performance of bimetallic screws can quickly complete the installation, and its corrosion resistance can ensure the reliability of the connection in long-term use.

Manufacturing industry: Commonly used in the assembly of mechanical equipment, the connection of the body and engine in automobile manufacturing, etc. On the automobile production line, bimetallic screws can firmly connect parts of different materials together, such as connecting plastic panels to metal body frames. Its good comprehensive performance can adapt to complex working conditions and frequent vibrations.

Electronic and electrical industry: In electronic equipment, it can be used for the installation of circuit boards and the grounding connection of various electrical equipment. Due to its good conductivity and corrosion resistance, it can ensure reliable electrical connection between electronic components and prevent electrical failures caused by screw corrosion.

Jiaxing Haina Fastener co. Ltd was established in 2010, located in the hometown of fasteners jiaxing city. For many years of export experience, our products has been best-selling in Europe, the United States, the Middle East and Southeast Asia. The products are manufactured by more functions machine, which is brought in domestic and foreign well-known enterprises. The products made are fully compatible with the international standards, well received by domestic and foreign customers.

What is the difference between galvanized screws and regular screws?

Galvanized screws are coated with a layer of zinc to resist corrosion, making them ideal for outdoor or wet environments. Regular screws lack this coating, making them more prone to rust and unsuitable for harsh conditions.

What is a bi-metal screw?

A bi-metal screw is a fastener made from two different metals, combining the strength of one metal (like steel) with the corrosion resistance or special properties of another (like stainless steel). This design ensures durability, strength, and adaptability for use in harsh environments like marine, construction, or chemical industries.

What screws are best for drilling into metal?

Self-drilling screws (Tek screws) are best for drilling into metal, as they have a built-in drill bit tip for effortless penetration. Choose screws made of hardened or stainless steel for durability and corrosion resistance.