- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HINA

HINA2024121206

The self-drilling screw is made of exquisite technology, with durability, high strength, no deformation, safety and environmental protection, beautiful and practical characteristics; Products can be used in a wide range, can be used in wood, brick wall, humid environment corrosion, kitchen rust, bathroom rust, doors, Windows and other indoor and outdoor can be used.

Usually composed of two different metal materials, it is common to use metals such as carbon steel that provide strength and hardness as the main part of the screw, and on the surface or key parts of the screw, such as the drill tip and head, it is combined with metals with special properties such as stainless steel, copper, and zinc.

For example, the drill tip of some bimetallic screws is made of heat-treated high-carbon steel to enhance drilling performance, while the main body and head of the screw are made of corrosion-resistant 304 or 316 stainless steel, which can ensure good drilling ability and excellent corrosion resistance.

| product name | Stainless Steel 304+410 Compound Hex Head Composite Self Drilling Bi-Metallic Screw | ||||||

| Material | Stainless Steel:SS304 SS410 | ||||||

| Finishing | Polishing, Plain, Sand Blasting | ||||||

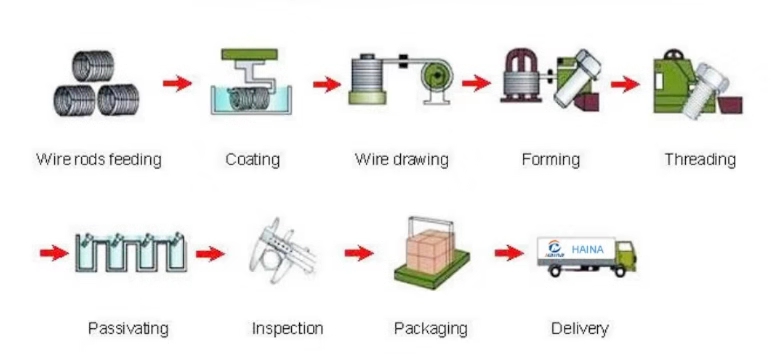

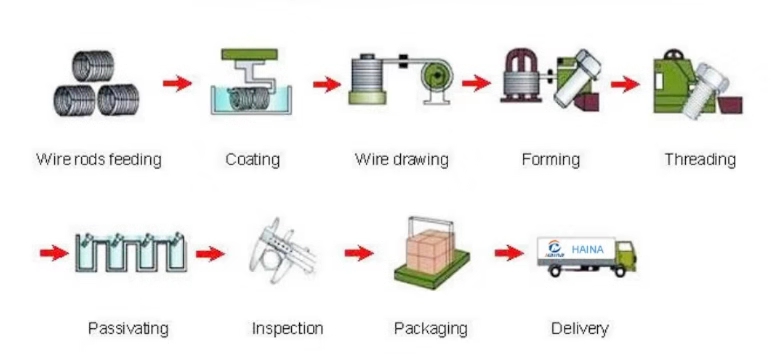

| Production Process | Cold Froging, Machining and CNC, Stamping, Welding | ||||||

| Customized Products Lead time | Busy season: 15-30days, Slack seaon: 10-15days | ||||||

| Stock Products | Stainless steel: DIN933, DIN603, DIN912, DIN6923, DIN934, DIN125, DIN127, DIN7504K | ||||||

| Free Samples for standard fastener | |||||||

Performance characteristics

Good corrosion resistance: The outer layer of stainless steel, zinc and other metal materials can effectively prevent the screws from rusting and corrosion in various harsh environments, such as humid, acidic and alkaline corrosive environments, greatly extending the service life. For example, in outdoor building structures, bimetallic screws can maintain good performance even if they are exposed to wind and rain for a long time.

Excellent mechanical properties: The internal carbon steel and other basic metal materials ensure that the screws have sufficient strength and toughness, can withstand large tensile and shear forces, and ensure the tightening effect. At the same time, the combination of different metals can also improve the wear resistance of screws to a certain extent, and reduce the damage to the screws themselves and the fastened parts during installation and removal.

Special electrical properties: When the outer metal is a material with good conductivity such as copper, bimetallic screws can be used to connect electrical equipment, which can ensure the stable passage of current, achieve good electrical conductivity, and ensure the normal operation of electrical equipment.

Professional Manufacturer: All of our Fastener are designed and manufactured according to buyers' specification and performance.

Quality is guaranteed: Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective: Competitive prices with professional factory supply

Perfect fastening solution with 10 years experiences to solve your problem: Wide range of parts selection.

Customized Ideal Fasteners: Customized services according to the samples and drawing offered

Certificate

RFQ

How do you control your quality.

We request QC inspect every productions links for each bacth goods. And we can provide you

MTC and mill certificate when the goods is finished.

The self-drilling screw is made of exquisite technology, with durability, high strength, no deformation, safety and environmental protection, beautiful and practical characteristics; Products can be used in a wide range, can be used in wood, brick wall, humid environment corrosion, kitchen rust, bathroom rust, doors, Windows and other indoor and outdoor can be used.

Usually composed of two different metal materials, it is common to use metals such as carbon steel that provide strength and hardness as the main part of the screw, and on the surface or key parts of the screw, such as the drill tip and head, it is combined with metals with special properties such as stainless steel, copper, and zinc.

For example, the drill tip of some bimetallic screws is made of heat-treated high-carbon steel to enhance drilling performance, while the main body and head of the screw are made of corrosion-resistant 304 or 316 stainless steel, which can ensure good drilling ability and excellent corrosion resistance.

| product name | Stainless Steel 304+410 Compound Hex Head Composite Self Drilling Bi-Metallic Screw | ||||||

| Material | Stainless Steel:SS304 SS410 | ||||||

| Finishing | Polishing, Plain, Sand Blasting | ||||||

| Production Process | Cold Froging, Machining and CNC, Stamping, Welding | ||||||

| Customized Products Lead time | Busy season: 15-30days, Slack seaon: 10-15days | ||||||

| Stock Products | Stainless steel: DIN933, DIN603, DIN912, DIN6923, DIN934, DIN125, DIN127, DIN7504K | ||||||

| Free Samples for standard fastener | |||||||

Performance characteristics

Good corrosion resistance: The outer layer of stainless steel, zinc and other metal materials can effectively prevent the screws from rusting and corrosion in various harsh environments, such as humid, acidic and alkaline corrosive environments, greatly extending the service life. For example, in outdoor building structures, bimetallic screws can maintain good performance even if they are exposed to wind and rain for a long time.

Excellent mechanical properties: The internal carbon steel and other basic metal materials ensure that the screws have sufficient strength and toughness, can withstand large tensile and shear forces, and ensure the tightening effect. At the same time, the combination of different metals can also improve the wear resistance of screws to a certain extent, and reduce the damage to the screws themselves and the fastened parts during installation and removal.

Special electrical properties: When the outer metal is a material with good conductivity such as copper, bimetallic screws can be used to connect electrical equipment, which can ensure the stable passage of current, achieve good electrical conductivity, and ensure the normal operation of electrical equipment.

Professional Manufacturer: All of our Fastener are designed and manufactured according to buyers' specification and performance.

Quality is guaranteed: Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective: Competitive prices with professional factory supply

Perfect fastening solution with 10 years experiences to solve your problem: Wide range of parts selection.

Customized Ideal Fasteners: Customized services according to the samples and drawing offered

Certificate

RFQ

How do you control your quality.

We request QC inspect every productions links for each bacth goods. And we can provide you

MTC and mill certificate when the goods is finished.