- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2025-06-09 Origin: Site

When you’re working with fasteners, you’ll often run into washers. These small but mighty components play a big role in keeping things secure. Washers in fastening applications help spread the load, protect surfaces, and even reduce vibrations. But not all washers are the same. Flat washers and lock washers each have their own job, and mixing them can get tricky. So, how do you know if you should pair them? Let’s dive into the facts to help you make the right choice.

Flat washers look simple but are very important in fastening. They are round with a hole in the middle. This shape spreads the fastener's pressure over a bigger area. It stops damage to softer surfaces underneath. Flat washers also help when surfaces are uneven. They make a smooth base for fasteners to stay tight. Without them, fasteners could loosen or harm the material over time.

Flat washers are made from different materials for various uses. Steel is strong and lasts a long time. Stainless steel doesn’t rust, so it’s good for wet places. Nylon washers don’t carry electricity, so they’re great for electrical work. Brass and aluminum washers are lightweight and resist corrosion. The material you pick depends on the job and environment.

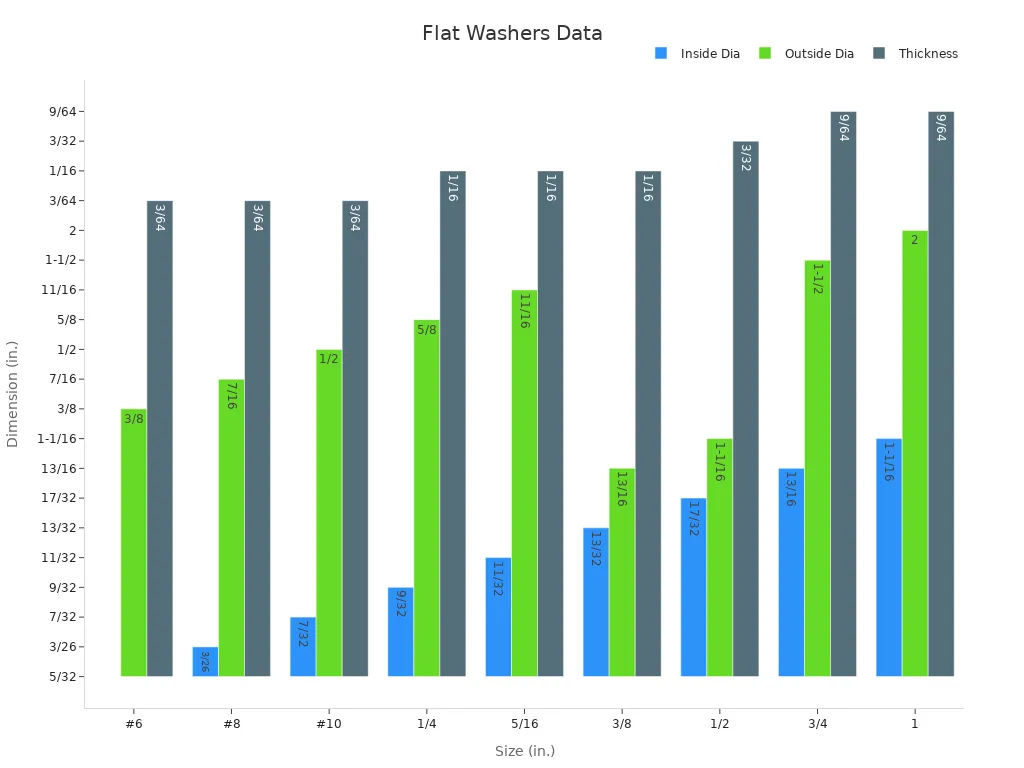

Flat washers are used in many industries like construction and car repairs. They protect surfaces and spread pressure evenly. For example, they stop bolts and nuts from damaging materials. Washers also reduce wear, helping fasteners last longer. Below is a table showing common washer sizes and their measurements:

Size (in.) | Inside diameter (in.) | Outside diameter (in.) | Thickness (in.) |

|---|---|---|---|

#6 | 5/32 | 3/8 | 3/64 |

#8 | 3/26 | 7/16 | 3/64 |

#10 | 7/32 | 1/2 | 3/64 |

¼ | 9/32 | 5/8 | 1/16 |

5/16 | 11/32 | 11/16 | 1/16 |

Flat washers are useful and dependable. They protect surfaces, add stability, and make fasteners last longer.

Lock washers are small parts that keep fasteners tight. They stop nuts and bolts from loosening due to shaking or turning. When tightened, lock washers grip the surface to create friction. This grip keeps fasteners from moving or spinning. Flat washers spread pressure, but lock washers focus on holding things firmly. Their special design makes them great for jobs with lots of movement.

Tip: Use lock washers for machines or structures that move often. They help avoid constant repairs.

Lock washers come in different shapes for various tasks. Here’s a quick list:

Helical (Split) Washers: These have a split shape that adds tension when tightened.

Internal-Tooth Washers: Teeth on the inside edge grip surfaces for shallow fasteners.

External-Tooth Washers: Teeth on the outside edge stop rotation and resist pressure.

Pyramidal Washers: These work well for jobs needing extra stability.

Dome-Type Washers: These are gentle yet firm for soft or thin materials.

Type of Lock Washer | Description |

|---|---|

Helical Lock Washer | A split coil that grips surfaces tightly when secured. |

External Tooth Lock Washer | Teeth on the outside edge stop rotation and resist pressure. |

Internal Tooth Lock Washer | Teeth on the inside edge grip surfaces for shallow fasteners. |

Lock washers are perfect for jobs with lots of shaking or movement. For example, they’re used in construction to keep steel parts secure. Adding lock washers helps prevent loose fasteners and improves stability. They’re also common in cars and electrical work, where tight connections are important.

Lock Washer Type | Description | Common Use Cases |

|---|---|---|

Split Lock Washers | Split design adds tension. | General-purpose jobs and easy to use. |

Internal Tooth Lock Washers | Inside teeth for gripping. | Used in cars and electrical work. |

External Tooth Lock Washers | Outside teeth for gripping. | Stops rotation and secures parts. |

Star Washers | Teeth all around for anti-rotation. | Prevents spinning in electrical connections. |

Lock washers are great for keeping fasteners tight in shaky environments. They save money on repairs and make things more reliable for tough jobs.

You might think using both flat washers and lock washers is smart. Flat washers spread pressure, and lock washers stop loosening, right? But their purposes don’t match. Flat washers make a smooth surface for fasteners. Lock washers need direct contact to grip and hold tight. If you put a flat washer between a lock washer and the surface, it messes up the lock washer’s job. This makes it harder for the lock washer to keep the fastener secure.

Here’s what studies show about this problem:

Evidence Type | Description |

|---|---|

Effectiveness Reduction | A flat washer can lower a lock washer’s strength by 40%. |

Increased Loosening Risk | Bolts are 50% more likely to loosen over time. |

Compression Loss | Grip pressure drops from 25,000 PSI to 10,000 PSI. |

Load Cycle Failure Rate | Failure rates rise by 30% when both washers are used. |

As you can see, combining these washers often causes more problems than it solves. Instead of improving performance, it weakens the fastener’s security.

Using both flat washersand lock washers weakens fasteners. Lock washers press tightly to stop loosening. Adding a flat washer spreads the load but lowers this pressure. The flat washer acts like a cushion, reducing the lock washer’s grip.

For example, the force needed for a strong grip drops from 25,000 PSI to 10,000 PSI when a flat washer is added. This weaker grip makes fasteners loosen faster, especially in vibrating machines. If you’re working on moving parts, this could mean more repairs or even failures.

Note: To stop loosening in moving systems, use only lock washers. They are made to handle vibrations without help.

The issues with combining flat washers and lock washers aren’t just theories. Engineers have seen these problems in real life. In tests, assemblies using both washers failed 30% more often than those with just lock washers. Over time, bolts in these setups loosened or broke under repeated stress.

In cars, mechanics have noticed similar issues. Using flat washers with lock washers in engines often causes bolts to loosen. The flat washer weakens the lock washer’s grip, especially with constant engine vibrations. This leads to more repairs and higher costs.

These examples show why it’s important to know the roles of each washer. Mixing them might seem helpful, but it usually hurts performance and reliability.

Using flat washers with lock washers might seem helpful, but it’s not. Lock washers are made to stop loosening by gripping surfaces tightly. Adding a flat washer between the lock washer and surface weakens this grip. The flat washer blocks the lock washer from holding firmly.

This setup lowers vibration resistance. Machines like engines or equipment need lock washers to stay tight. Adding flat washers makes bolts loosen faster over time. In high-vibration areas, this can cause frequent repairs or even system failure.

Tip: Skip the flat washer when using lock washers. Let the lock washer grip the surface directly.

Flat washers and lock washers do different jobs. Mixing them causes compression issues. Flat washers spread pressure, while lock washers create tension to hold fasteners. Using both reduces the pressure the lock washer needs to work well.

For example, a lock washer alone can handle 25,000 PSI. Adding a flat washer drops this to 10,000 PSI. This weaker compression makes bolts loosen faster under heavy loads or stress.

In critical projects like bridges or machines, this loss of strength can cause failures. Always check your project needs before choosing washers.

Combining flat washers and lock washers weakens fasteners and costs more money. Loose bolts mean more repairs and maintenance.

Studies show appliances with bad parts fail often:

Washing machines with drum issues need repairs 27% of the time.

Dishwashers with pump problems break 58% of the time.

Appliances with multiple failures, like bearings, have a 47% repair rate.

These examples show how mixing washers can lead to higher failure rates. In factories, this means downtime and extra expenses.

Note: Use washers that match your project needs. Avoid flat washers when lock washers are required. This saves money and keeps systems reliable.

Choosing the right washer is very important. Think about the material, size, and how it will be used. For example, stainless steel is great in wet places because it doesn’t rust. Nylon washers are perfect for electrical work since they don’t carry electricity. Always match the washer size to the bolt or screw. A washer that’s too small won’t spread pressure well. One that’s too big might not fit tightly.

Here’s a quick guide to help you choose:

Consideration | Details |

|---|---|

Material Choice | Use stainless steel for rust resistance in wet areas. |

Size and Thickness | Match washer size to bolt/screw; thickness spreads pressure evenly. |

Installation Steps | Install correctly and maintain regularly for better performance. |

Follow these tips to keep your fasteners secure and working well.

The order of washers matters a lot. If using a flat washer, place it under the bolt head or nut. This helps spread the pressure evenly. Lock washers need to touch the surface directly to grip well. Never put a flat washer between a lock washer and the surface. This weakens the lock washer’s grip.

Remember this rule: flat washers go first to protect surfaces. Lock washers come next to stop loosening. If using only one type, install it properly for the best results.

Vibrations can loosen fasteners over time, especially in machines or cars. To prevent this, use lock washers. They grip tightly and stop movement. Spring washers are also good for handling vibrations and keeping tension. Always check washers before using them. Worn-out washers won’t work well.

For extra safety, use thread-locking glue with your washers. This glue helps stop loosening. Regularly check your fasteners to find problems early.

By following these steps, you’ll keep fasteners tight even in tough conditions.

Flat washers and lock washers have different jobs, but using them together can cause issues. It lowers tension, weakens vibration resistance, and increases failure chances. This can make your project unsafe, especially in tough conditions.

Pick washers that fit your project’s needs for the best results. Install them correctly to keep fasteners tight and secure. This will save you time, prevent expensive fixes, and make your assemblies dependable.

Flat washers spread pressure and protect surfaces. Lock washers stop fasteners from loosening. Flat washers make a smooth base, while lock washers grip tightly to handle vibrations. Each has a specific job, so pick based on your project.

It’s not a good idea. Flat washers reduce how well lock washers grip. This weakens their ability to stop loosening. Using both can lower tension and increase failure risks, especially in vibrating systems. Choose one type for your task.

Pick a material that fits your environment. Stainless steel is great for wet areas. Nylon is ideal for electrical work. Brass and aluminum are lightweight and resist rust. Always think about the conditions your fastener will face.

No, lock washers are best for moving parts like machines or cars. For still parts, flat washers or no washers may work fine. Think about how much movement or stress your project will have before choosing.

If using both types (though not advised), place the flat washer first to protect the surface. Then add the lock washer to stop loosening. For one washer, make sure it touches the surface directly for the best hold.