- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

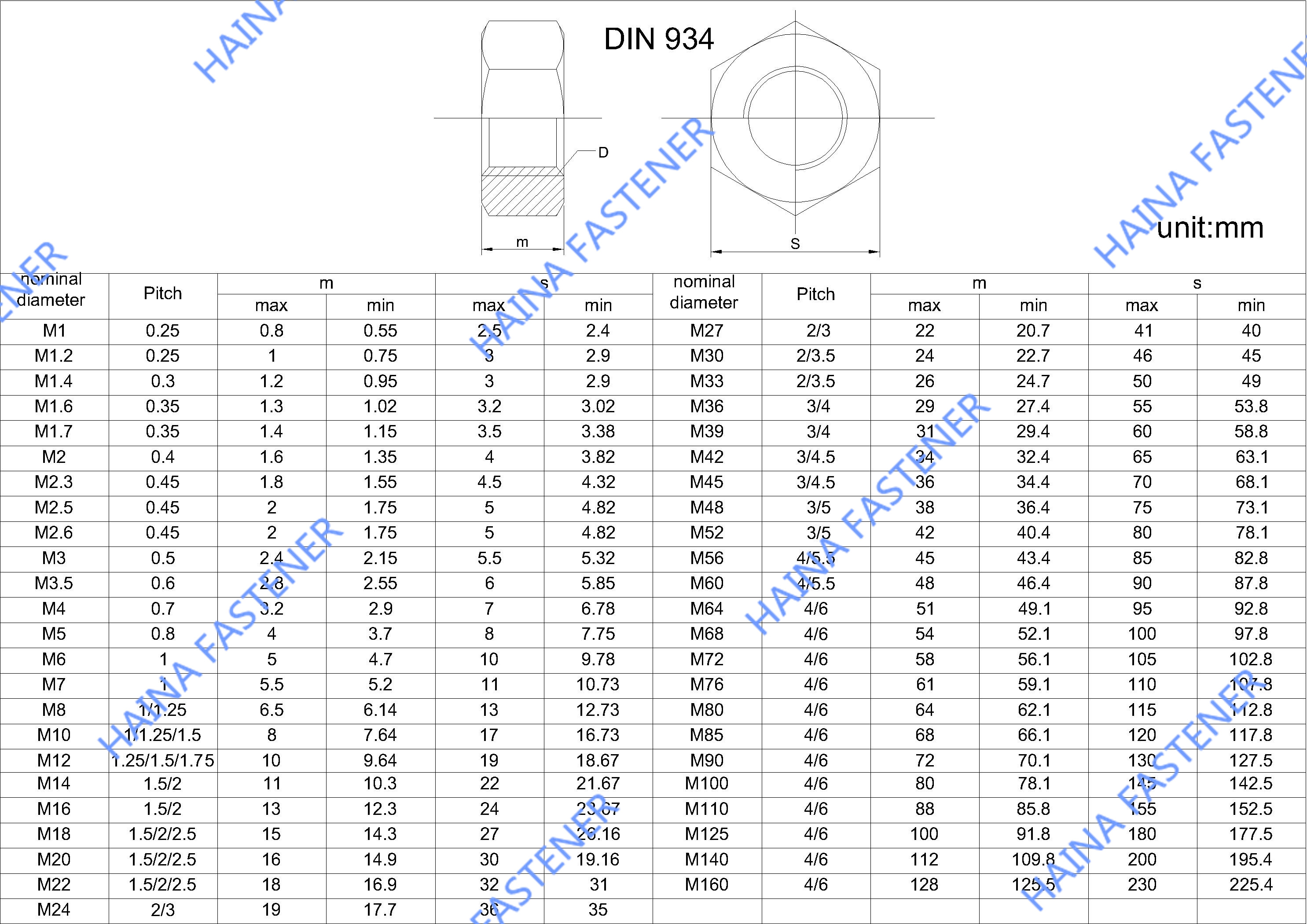

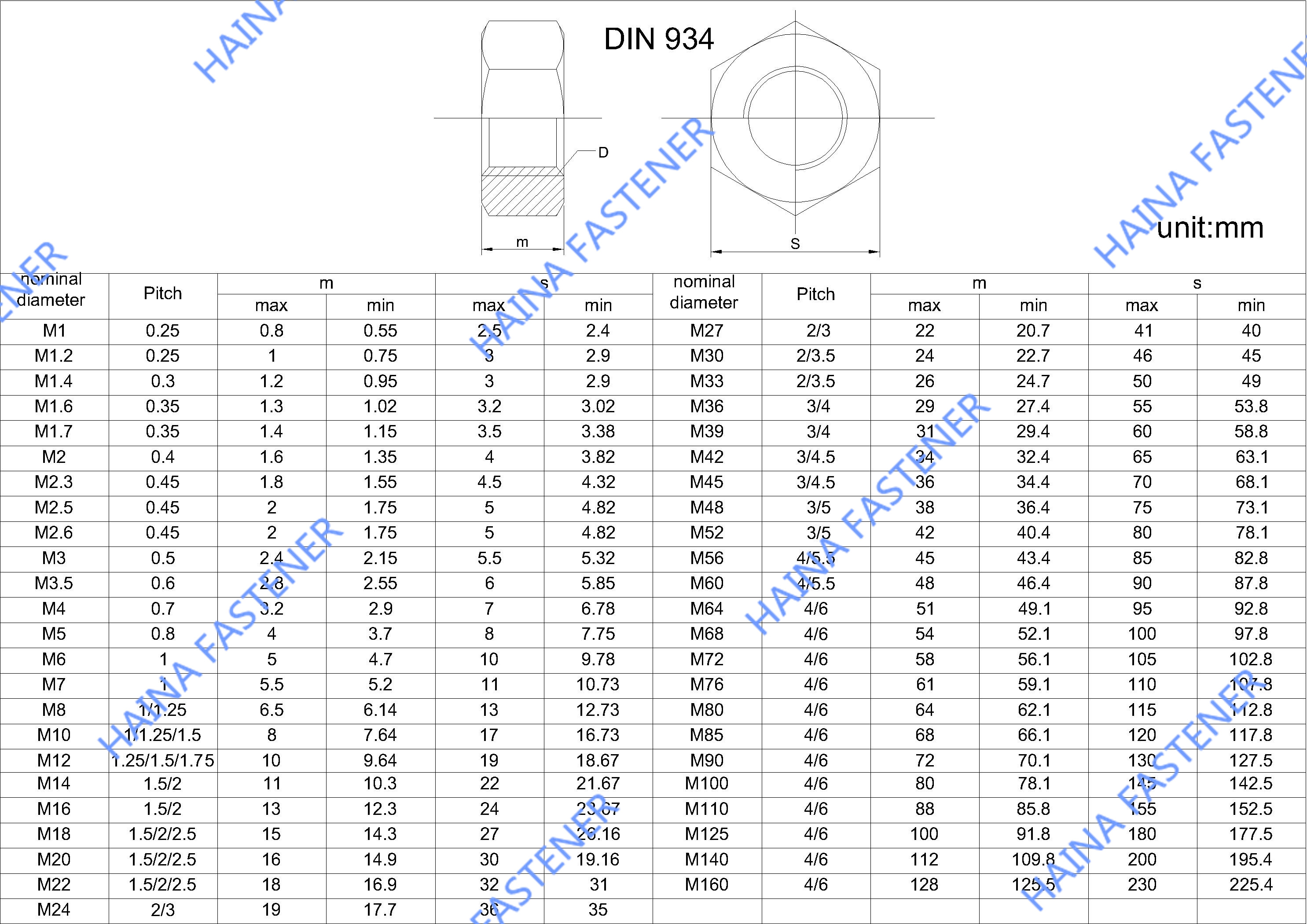

DIN934

HNF

HINA2025012301

Yellow zinc - plated hexagonal nuts are hexagonal nuts that have undergone a yellow zinc - plating treatment based on natural - finish hexagonal nuts. While maintaining the basic shape and function of hexagonal nuts, a layer of zinc coating is formed on the surface through an electroplating process, presenting a yellow appearance. This zinc coating not only changes the appearance color of the nut but, more importantly, provides additional protective properties to the nut.

Good corrosion resistance: Zinc has excellent anti - corrosion properties. The yellow zinc coating can effectively isolate the contact between the nut substrate and air, moisture, and other corrosive substances, slowing down the rusting and corrosion rate of the nut and extending its service life. It is especially suitable for some harsh working environments, such as those with moisture, acids, alkalis, and other corrosive media.

Attractive appearance: The yellow zinc coating gives the nut a bright yellow appearance. Compared with natural - finish hexagonal nuts, it has a better visual effect. In some equipment or products with certain requirements for appearance, it can enhance the overall aesthetics and quality.

Good lubricity: During the electroplating process, the surface of the zinc layer is relatively smooth and has certain self - lubricating properties. This makes the yellow zinc - plated hexagonal nut have relatively low friction when it is screwed together with a bolt or screw rod. Installation and disassembly are smoother, reducing wear and heat generated by friction and improving the assembly efficiency.

Good weldability: Zinc has good weldability. In occasions where welding operations are required, yellow zinc - plated hexagonal nuts can be welded well to other metal parts, ensuring the firmness and reliability of the connection and providing convenience for some complex assembly and manufacturing processes.

Construction industry: In construction projects, it is used for the connection of steel structures, the construction of scaffolding, and the fixation of some outdoor facilities. Its good corrosion resistance can withstand the erosion of the outdoor environment, ensuring the safety and stability of the building structure.

Automotive manufacturing: It is widely used in parts such as the chassis, body, and engine of automobiles. For example, it is used to fix the suspension system components of the car chassis, connect the body frame, and install some auxiliary equipment of the engine. It can not only ensure the tightness of the connection but also resist the erosion of mud and water splashed on the road during the car's driving.

Power equipment: In power transmission and distribution equipment, it is used to connect wire and cable joints and fix the components of electrical equipment. Its good electrical conductivity and corrosion resistance help ensure the stability and safety of power transmission, preventing problems such as poor contact and electric leakage caused by corrosion.

Mechanical equipment: Yellow zinc - plated hexagonal nuts are often used in the assembly and maintenance of various industrial machinery, agricultural machinery, mining machinery, and other equipment. They are used to connect and fix mechanical components such as gearboxes, drive shafts, and pulleys. They can withstand vibrations and impacts during the operation of the machinery and resist the erosion of oil, water vapor, etc. in the working environment.

Daily necessities: It is also applied in some daily necessities such as furniture, doors and windows, and hardware tools. For example, in the assembly of furniture and the fixation of door and window hinges, its beautiful appearance and good performance can meet the needs of daily use and decoration.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

What are the strength grades of carbon steel hexagon nuts?

Common strength grades include 4.8, 8.8, 10.9, 12.9, etc. The number before the decimal point represents 1/100 of the nominal tensile strength, and the number after the decimal point is 10 times the yield strength ratio. The larger the number, the higher the strength.

What is the difference between carbon steel hexagonal nuts and stainless steel hexagonal nuts?

In terms of material, carbon steel is mainly an iron-carbon alloy, and stainless steel adds elements such as chromium and nickel; in terms of performance, stainless steel has strong rust resistance and corrosion resistance, while carbon steel is relatively poor; in terms of price, stainless steel hexagonal nuts are usually more expensive than carbon steel due to material and processing costs.

Yellow zinc - plated hexagonal nuts are hexagonal nuts that have undergone a yellow zinc - plating treatment based on natural - finish hexagonal nuts. While maintaining the basic shape and function of hexagonal nuts, a layer of zinc coating is formed on the surface through an electroplating process, presenting a yellow appearance. This zinc coating not only changes the appearance color of the nut but, more importantly, provides additional protective properties to the nut.

Good corrosion resistance: Zinc has excellent anti - corrosion properties. The yellow zinc coating can effectively isolate the contact between the nut substrate and air, moisture, and other corrosive substances, slowing down the rusting and corrosion rate of the nut and extending its service life. It is especially suitable for some harsh working environments, such as those with moisture, acids, alkalis, and other corrosive media.

Attractive appearance: The yellow zinc coating gives the nut a bright yellow appearance. Compared with natural - finish hexagonal nuts, it has a better visual effect. In some equipment or products with certain requirements for appearance, it can enhance the overall aesthetics and quality.

Good lubricity: During the electroplating process, the surface of the zinc layer is relatively smooth and has certain self - lubricating properties. This makes the yellow zinc - plated hexagonal nut have relatively low friction when it is screwed together with a bolt or screw rod. Installation and disassembly are smoother, reducing wear and heat generated by friction and improving the assembly efficiency.

Good weldability: Zinc has good weldability. In occasions where welding operations are required, yellow zinc - plated hexagonal nuts can be welded well to other metal parts, ensuring the firmness and reliability of the connection and providing convenience for some complex assembly and manufacturing processes.

Construction industry: In construction projects, it is used for the connection of steel structures, the construction of scaffolding, and the fixation of some outdoor facilities. Its good corrosion resistance can withstand the erosion of the outdoor environment, ensuring the safety and stability of the building structure.

Automotive manufacturing: It is widely used in parts such as the chassis, body, and engine of automobiles. For example, it is used to fix the suspension system components of the car chassis, connect the body frame, and install some auxiliary equipment of the engine. It can not only ensure the tightness of the connection but also resist the erosion of mud and water splashed on the road during the car's driving.

Power equipment: In power transmission and distribution equipment, it is used to connect wire and cable joints and fix the components of electrical equipment. Its good electrical conductivity and corrosion resistance help ensure the stability and safety of power transmission, preventing problems such as poor contact and electric leakage caused by corrosion.

Mechanical equipment: Yellow zinc - plated hexagonal nuts are often used in the assembly and maintenance of various industrial machinery, agricultural machinery, mining machinery, and other equipment. They are used to connect and fix mechanical components such as gearboxes, drive shafts, and pulleys. They can withstand vibrations and impacts during the operation of the machinery and resist the erosion of oil, water vapor, etc. in the working environment.

Daily necessities: It is also applied in some daily necessities such as furniture, doors and windows, and hardware tools. For example, in the assembly of furniture and the fixation of door and window hinges, its beautiful appearance and good performance can meet the needs of daily use and decoration.

Our service

Professional Manufacturer : All of our Fastener are designed and manufactured according to buyers'specification and performance.

Quality is guaranteed : Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective : Wide range of parts selection , Competitive prices with professional factory supply.

Customized ideal Fasteners : customized services according to the samples and drawing offered.

Certification

Through scientific management, Jiaxing Haina fastener Ltd company has been obtained ISO9000 certificate of Quality Managerment System, SGS and BV international certificate system of Make in China.

What are the strength grades of carbon steel hexagon nuts?

Common strength grades include 4.8, 8.8, 10.9, 12.9, etc. The number before the decimal point represents 1/100 of the nominal tensile strength, and the number after the decimal point is 10 times the yield strength ratio. The larger the number, the higher the strength.

What is the difference between carbon steel hexagonal nuts and stainless steel hexagonal nuts?

In terms of material, carbon steel is mainly an iron-carbon alloy, and stainless steel adds elements such as chromium and nickel; in terms of performance, stainless steel has strong rust resistance and corrosion resistance, while carbon steel is relatively poor; in terms of price, stainless steel hexagonal nuts are usually more expensive than carbon steel due to material and processing costs.