- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

DIN6331

HNF

HINA2025012004

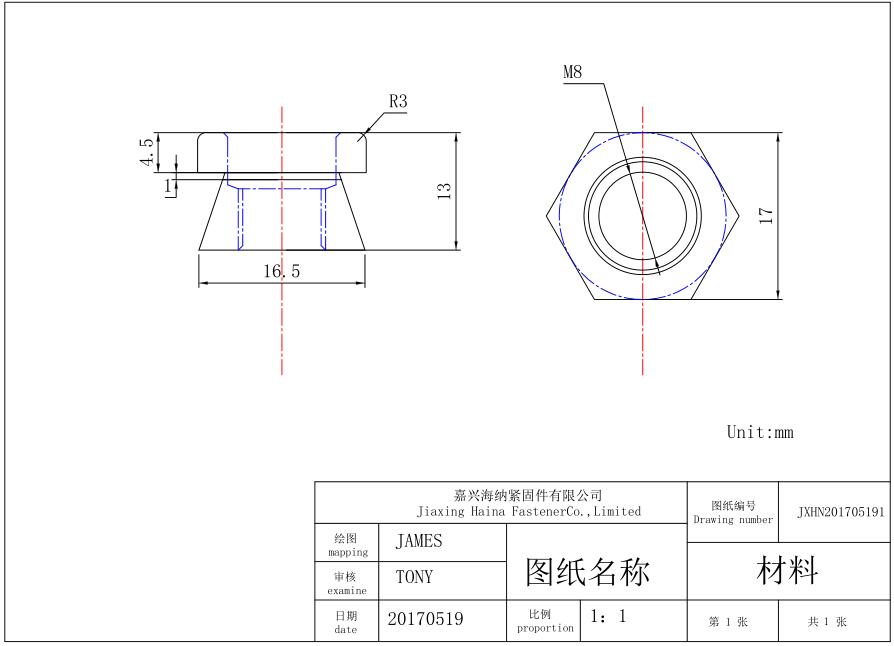

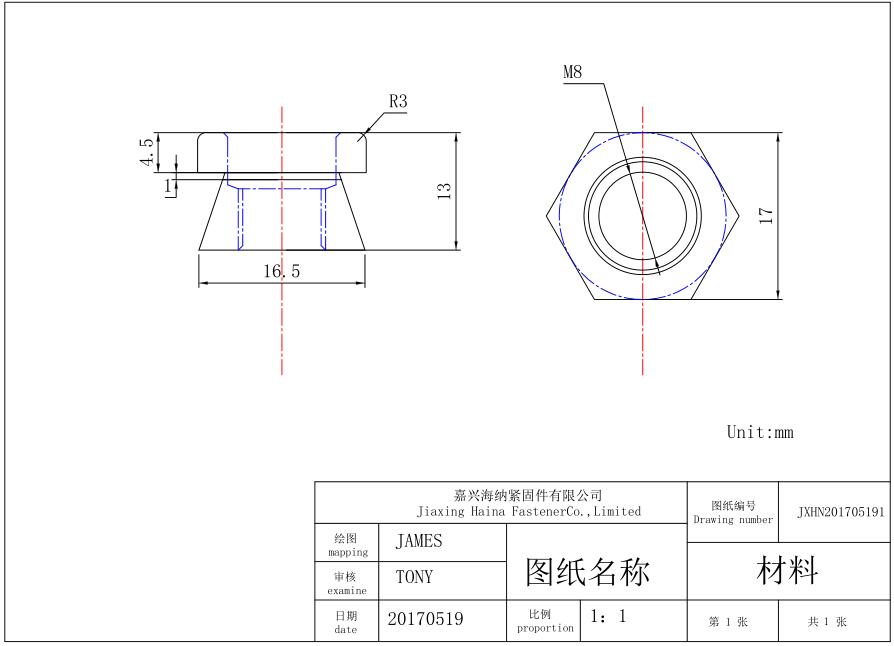

DIN 6331 is a standard for flange nuts, commonly used in mechanical and construction industries. The design feature of this nut is a larger flange (a protruding circular edge) on one side, which increases the contact area, helping to distribute the load and enhance stability.

Flange Design:

The DIN 6331 flange nut has a large flange on one side, which increases the contact area with the mating surface, providing better load-bearing capacity.

Increased Stability:

The flange helps prevent the nut from loosening, especially in environments with vibrations or repeated loads, offering improved anti-loosening performance.

Standardization:

DIN 6331 is a German industrial standard (DIN) that ensures uniformity in the nut's size, material, and performance, making it easier to apply and interchange worldwide.

Sizes and Materials:

DIN 6331 flange nuts are available in various sizes to accommodate different thread specifications. Common materials include steel, stainless steel, and some products are treated for corrosion resistance, such as zinc plating.

Mechanical Equipment:

In mechanical equipment and machinery components, DIN 6331 flange nuts are commonly used for connections that require high load-bearing capacity and stability.

Construction Structures:

Used in construction for fastening and securing components, especially in applications subjected to high pressure and vibration.

Automotive and Marine:

In automotive and marine applications, flange nuts enhance the stability of bolt connections and prevent loosening.

Overall, DIN 6331 flange nuts are widely used in various industrial and construction fields due to their large contact area and strong anti-loosening capability.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

What are the advantages of using a flange nut?

The flange provides additional support and distributes the load evenly, which reduces the risk of damaging the surface. It also eliminates the need for a separate washer in many cases.

What is a nut in mechanical terms?

A nut is a hexagonal or other-shaped metal fastener with a hole in the center that fits over a bolt, allowing two parts to be securely joined together.

DIN 6331 is a standard for flange nuts, commonly used in mechanical and construction industries. The design feature of this nut is a larger flange (a protruding circular edge) on one side, which increases the contact area, helping to distribute the load and enhance stability.

Flange Design:

The DIN 6331 flange nut has a large flange on one side, which increases the contact area with the mating surface, providing better load-bearing capacity.

Increased Stability:

The flange helps prevent the nut from loosening, especially in environments with vibrations or repeated loads, offering improved anti-loosening performance.

Standardization:

DIN 6331 is a German industrial standard (DIN) that ensures uniformity in the nut's size, material, and performance, making it easier to apply and interchange worldwide.

Sizes and Materials:

DIN 6331 flange nuts are available in various sizes to accommodate different thread specifications. Common materials include steel, stainless steel, and some products are treated for corrosion resistance, such as zinc plating.

Mechanical Equipment:

In mechanical equipment and machinery components, DIN 6331 flange nuts are commonly used for connections that require high load-bearing capacity and stability.

Construction Structures:

Used in construction for fastening and securing components, especially in applications subjected to high pressure and vibration.

Automotive and Marine:

In automotive and marine applications, flange nuts enhance the stability of bolt connections and prevent loosening.

Overall, DIN 6331 flange nuts are widely used in various industrial and construction fields due to their large contact area and strong anti-loosening capability.

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

What are the advantages of using a flange nut?

The flange provides additional support and distributes the load evenly, which reduces the risk of damaging the surface. It also eliminates the need for a separate washer in many cases.

What is a nut in mechanical terms?

A nut is a hexagonal or other-shaped metal fastener with a hole in the center that fits over a bolt, allowing two parts to be securely joined together.