- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

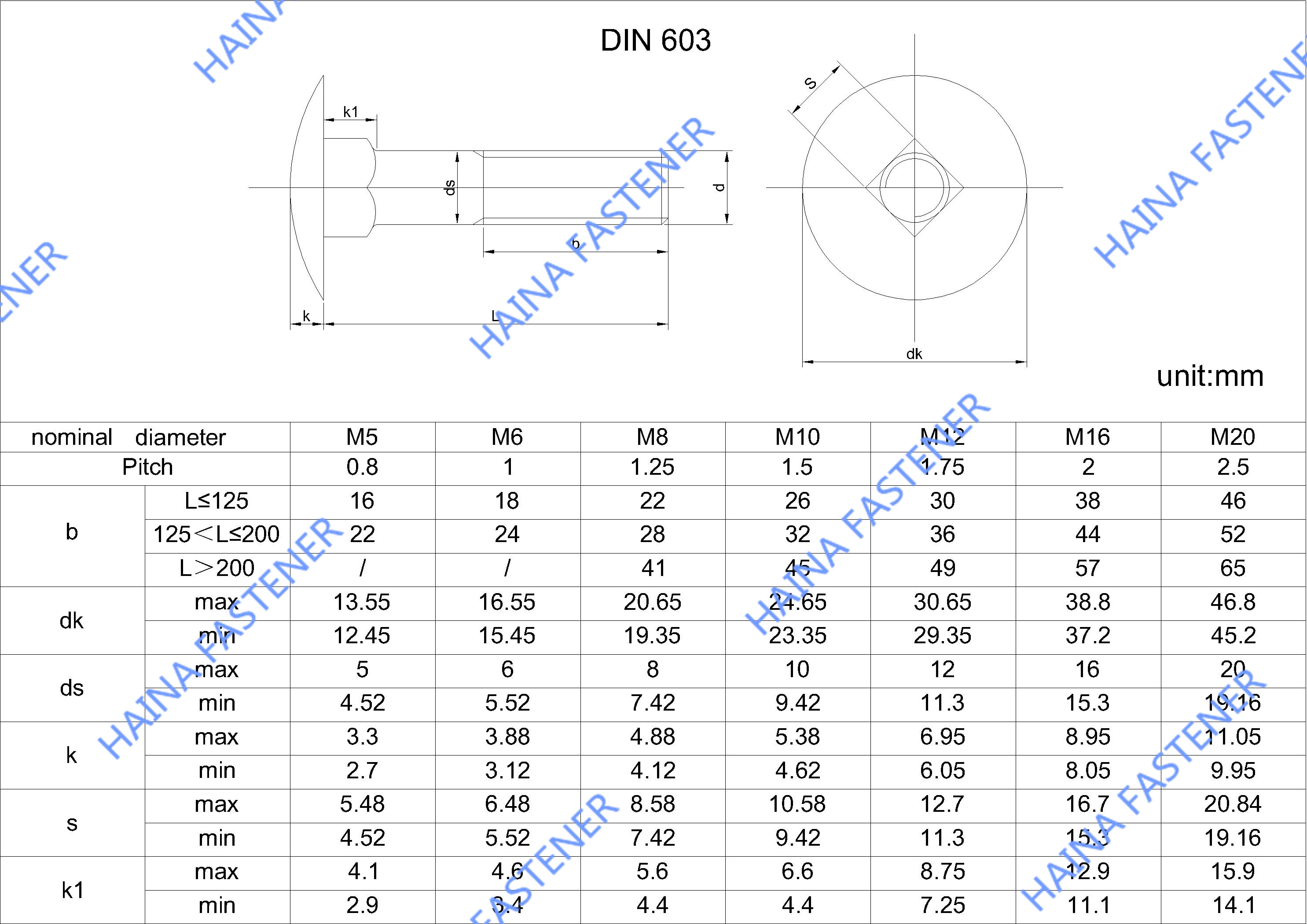

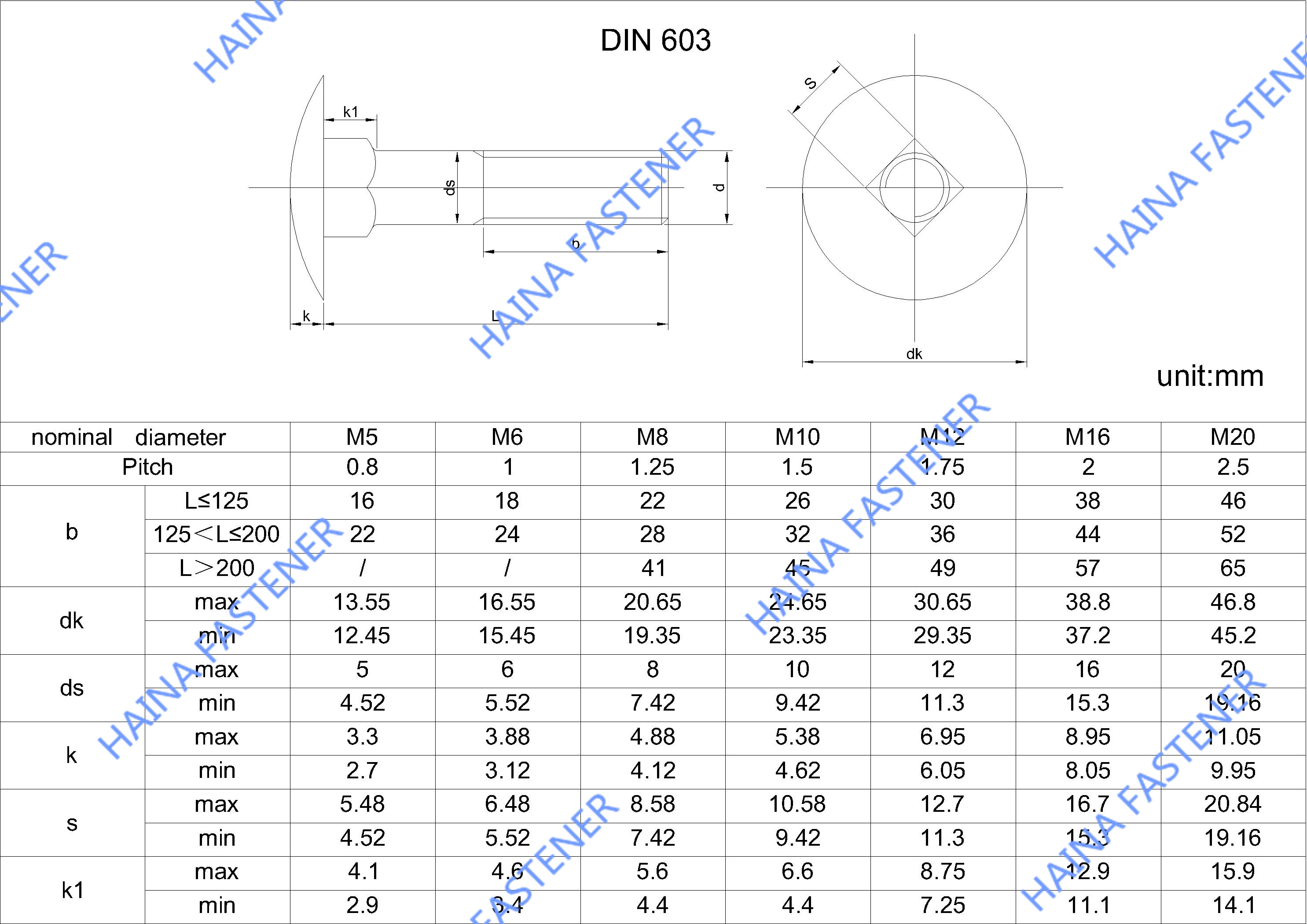

DIN603

HNF

HNF2024112101

Carbon Steel DIN603 4.8Grade Blue And White Zinc Galvanized Carriage Bolts

Product Description

Carbon steel carriage bolts are bolts commonly used for connecting wood and metal. They are made of carbon steel and have high strength and durability.

1. Large Flat Head design:

- The Large Flat Head has no edges and corners, which is safe and beautiful. It is often used in situations where it is necessary to prevent catching.

2. Square neck anti-slip:

- The square neck design under the Large Flat Head head can be embedded in the wood or metal surface to prevent the bolt from rotating, which is convenient for single-sided installation.

3. Carbon steel material:

- It has high hardness and good strength.

- It can be galvanized or other anti-corrosion treatment, suitable for outdoor and humid environments.

Product Details

Production Process

Product Feature

Application scenarios:

1. Wood structure connection:

- It is used for fastening and splicing of wooden beams and wooden boards.

2. Metal frame assembly:

- It is commonly used in the fixing of metal parts in construction and mechanical equipment.

3. Furniture manufacturing:

- It is used for furniture assembly where the threaded end needs to be hidden.

4. Outdoor engineering:

- The fixing of bridges, guardrails or other outdoor wooden structures, especially in situations with high corrosion resistance requirements.

Advantages:

- Easy installation, square neck anti-rotation function reduces the complexity of operation.

- Round head design is safe and beautiful, suitable for a variety of scenarios.

- Carbon steel material has high strength and adapts to a variety of load requirements.

Carbon steel carriage bolts are a common and reliable fastener in construction, furniture, and outdoor projects.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1. What are the common surface treatment methods for carbon steel carriage bolts?

The most common is galvanizing, including electrogalvanizing and hot-dip galvanizing. The electrogalvanized layer is more uniform and has a better appearance. It is suitable for occasions with high requirements for appearance, such as indoor furniture, etc.; the hot-dip galvanized layer is thicker and has better anti-corrosion performance. It is generally used outdoors or in environments with high anti-corrosion requirements. In addition, there are nickel plating, chrome plating and other treatment methods. Nickel plating can improve the corrosion resistance and decorativeness of the bolts, and chrome plating is mainly used to improve the wear resistance and decorativeness of the bolts.

2. What is galvanizing?

Electrogalvanizing is a relatively broad concept. It is a process of depositing a zinc layer on the metal surface by electrolysis. Depending on the post-treatment process and additives, a variety of galvanized layers with different appearances and performances can be produced. In addition to blue and white zinc, there are also galvanized layers of different colors such as colored zinc, black zinc, and military green zinc. It can effectively prevent the carriage bolts from contacting with corrosive media such as water and oxygen from the outside, thereby increasing the life of the carriage bolts.

3. What are the precautions for using carbon steel carriage bolts in different environments?

In a humid environment, since carbon steel is prone to rust, special attention should be paid to the anti-corrosion of the bolts. If the bolts are galvanized, the zinc layer should be checked regularly for damage. If damaged, the bolts should be repaired or replaced in time. In a high temperature environment, the thermal expansion coefficient of carbon steel should be considered to avoid loose connections due to temperature changes. At the same time, when subjected to dynamic loads (such as vibration environments), care should be taken to prevent the bolts from loosening. Anti-loosening measures such as adding spring washers can be adopted.

Carbon Steel DIN603 4.8Grade Blue And White Zinc Galvanized Carriage Bolts

Product Description

Carbon steel carriage bolts are bolts commonly used for connecting wood and metal. They are made of carbon steel and have high strength and durability.

1. Large Flat Head design:

- The Large Flat Head has no edges and corners, which is safe and beautiful. It is often used in situations where it is necessary to prevent catching.

2. Square neck anti-slip:

- The square neck design under the Large Flat Head head can be embedded in the wood or metal surface to prevent the bolt from rotating, which is convenient for single-sided installation.

3. Carbon steel material:

- It has high hardness and good strength.

- It can be galvanized or other anti-corrosion treatment, suitable for outdoor and humid environments.

Product Details

Production Process

Product Feature

Application scenarios:

1. Wood structure connection:

- It is used for fastening and splicing of wooden beams and wooden boards.

2. Metal frame assembly:

- It is commonly used in the fixing of metal parts in construction and mechanical equipment.

3. Furniture manufacturing:

- It is used for furniture assembly where the threaded end needs to be hidden.

4. Outdoor engineering:

- The fixing of bridges, guardrails or other outdoor wooden structures, especially in situations with high corrosion resistance requirements.

Advantages:

- Easy installation, square neck anti-rotation function reduces the complexity of operation.

- Round head design is safe and beautiful, suitable for a variety of scenarios.

- Carbon steel material has high strength and adapts to a variety of load requirements.

Carbon steel carriage bolts are a common and reliable fastener in construction, furniture, and outdoor projects.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1. What are the common surface treatment methods for carbon steel carriage bolts?

The most common is galvanizing, including electrogalvanizing and hot-dip galvanizing. The electrogalvanized layer is more uniform and has a better appearance. It is suitable for occasions with high requirements for appearance, such as indoor furniture, etc.; the hot-dip galvanized layer is thicker and has better anti-corrosion performance. It is generally used outdoors or in environments with high anti-corrosion requirements. In addition, there are nickel plating, chrome plating and other treatment methods. Nickel plating can improve the corrosion resistance and decorativeness of the bolts, and chrome plating is mainly used to improve the wear resistance and decorativeness of the bolts.

2. What is galvanizing?

Electrogalvanizing is a relatively broad concept. It is a process of depositing a zinc layer on the metal surface by electrolysis. Depending on the post-treatment process and additives, a variety of galvanized layers with different appearances and performances can be produced. In addition to blue and white zinc, there are also galvanized layers of different colors such as colored zinc, black zinc, and military green zinc. It can effectively prevent the carriage bolts from contacting with corrosive media such as water and oxygen from the outside, thereby increasing the life of the carriage bolts.

3. What are the precautions for using carbon steel carriage bolts in different environments?

In a humid environment, since carbon steel is prone to rust, special attention should be paid to the anti-corrosion of the bolts. If the bolts are galvanized, the zinc layer should be checked regularly for damage. If damaged, the bolts should be repaired or replaced in time. In a high temperature environment, the thermal expansion coefficient of carbon steel should be considered to avoid loose connections due to temperature changes. At the same time, when subjected to dynamic loads (such as vibration environments), care should be taken to prevent the bolts from loosening. Anti-loosening measures such as adding spring washers can be adopted.