- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2024-05-10 Origin: Site

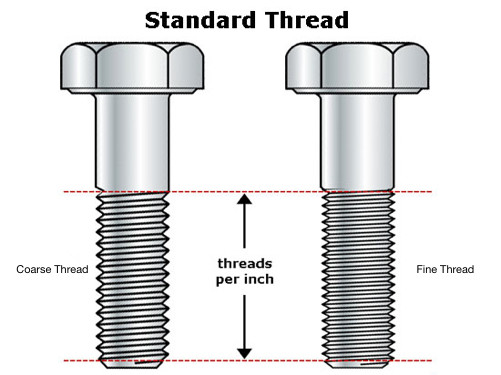

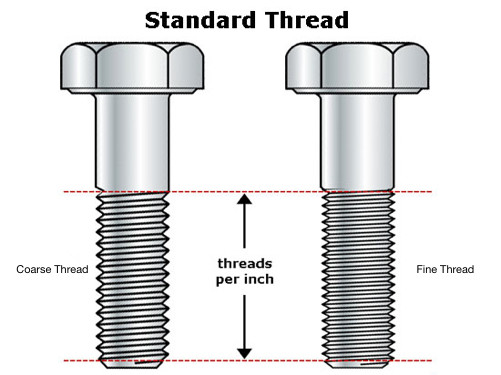

To what extent can a thread be called a fine thread? We might as well define it this way. Coarse threads can be defined as standard threads; while fine threads are relatively coarse threads. Under the same nominal diameter, the number of teeth per inch is different, that is, the pitch is different, and the coarse threads are different. The pitch of the thread is large, while the pitch of the fine thread is small.

In other words, for the two specifications of 1/2-13 and 1/2-20, the former has coarse teeth and the latter has fine teeth. Therefore expressed as 1/2-13UNC and 1/2-20UNF.

Since there are two different thread specifications with the same nominal diameter, how to choose between coarse thread and fine thread?

Coarse Thread

Coarse threads actually refer to standard threads. Unless otherwise specified, the stainless steel screws and other fasteners we generally buy are coarse threads.

Coarse threads are characterized by high strength, good interchangeability, and there are standards for comparison. Generally speaking, coarse threads should be the best choice;

Compared with fine threads, due to the large pitch and large thread rise angle, the self-locking property is poor. In a vibration environment, anti-loosening washers and self-locking devices need to be installed. The advantage is that it is easy to disassemble and assemble, and the supporting standard parts are complete. , easy to interchange;

There is no need to mark the pitch when marking coarse threads, such as M8, M12-6H, M16-7H, etc., which are mainly used for connecting threads.

Fine Thread

Fine threads and coarse threads are exactly the opposite. They are stipulated to supplement the special use requirements that coarse threads cannot meet. Fine threads also have a pitch series. The pitch of fine threads is smaller, so its characteristics are more conducive to self-locking and anti-loosening. And having more teeth can reduce leakage and achieve a better sealing effect. In some precision situations, fine-thread stainless steel screws are more convenient for precise control and adjustment.

The disadvantage is that the tensile value and strength are lower than those of coarse threads, and the threads are easily damaged. It is not recommended to disassemble and assemble multiple times. The matching nuts and other fasteners may be equally accurate, and there may be slight errors in size, which may easily cause the screws and nuts to be damaged at the same time.

Fine threads are mainly used in metric pipe fittings of hydraulic systems, mechanical transmission parts, thin-walled parts with insufficient strength, internal parts subject to space constraints, and shafts with high self-locking requirements. When marking fine threads, the pitch must be marked to show the difference from coarse threads.

How To Choose Between Coarse And Fine Threads?

Coarse thread and fine thread screws are both used for fastening.

Fine-thread screws are generally used to lock thin-walled parts and parts that require higher anti-vibration requirements. Fine threads have good self-locking properties, so they have strong resistance to vibration and loosening. However, due to the shallow depth of the threads, their ability to withstand greater pulling force is worse than that of coarse threads.

When no anti-loosening measures are taken, the anti-loosening effect of fine-thread threads is better than that of coarse-thread threads. They are generally used for thin-walled parts and parts with relatively high anti-vibration requirements.

When making adjustments, fine threads have more advantages. Disadvantages of fine thread: It is not suitable for use on materials with too thick structure and poor strength. When the tightening force is too large, it is easy to slip.

content is empty!