- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

19X90

HNF

20170612

The shear stud are fasteners with high strength stiffness connection. The shear studs are abbreviated as the cylindrical studs ( Cheese head studs for arc stud welding). The specifications of theshear studs are nominal diameter Ф10 ~ Ф25mm, The total length of the welding before the 40 ~ 300 mm. The nail has the top of the head with the glyphs to make the manufacturer's identification mark, the use of welding nail is very wide.

Shear Connector Studs are designed to tie the concrete slab to the steel beams and to resist shear loadings between the concrete slab and steel beam in composite construction. This enables us to load up to 1000 kg/m2 instead of the usual load which is much less. The procedure saves time and therefore money as well due to its simplicity.

Ceramic Ferrule (Shear Stud Welding Ceramic Ring ) is for shear stud connector welding applied for through steel deck welding or steel beam ceramic ferrule stud welding project. The ceramic ferrules are made of cordierite and able to withstand heat shock as well as high temperatures without melting or breaking.

It's necessary part for shear studs welding, designed with the following functions:

◇The ceramic ferrules make the shear studs welding connection point metal water easy forming, let the shear connectors with steel beam connect more solide and more tight

◇Prevent the damage of stud welder gun and welding gun components assemblage like stud chucks during the shear studs welding work.

◇To Reducing the arc welding spatter and smoke damage to workers

ceramic ferrules are produced as ISO13918:2008 standard with high hardness and High temperature resistant, can significant improve the weld result.

The shear stud are fasteners with high strength stiffness connection. The shear studs are abbreviated as the cylindrical studs ( Cheese head studs for arc stud welding). The specifications of theshear studs are nominal diameter Ф10 ~ Ф25mm, The total length of the welding before the 40 ~ 300 mm. The nail has the top of the head with the glyphs to make the manufacturer's identification mark, the use of welding nail is very wide.

Shear Connector Studs are designed to tie the concrete slab to the steel beams and to resist shear loadings between the concrete slab and steel beam in composite construction. This enables us to load up to 1000 kg/m2 instead of the usual load which is much less. The procedure saves time and therefore money as well due to its simplicity.

Ceramic Ferrule (Shear Stud Welding Ceramic Ring ) is for shear stud connector welding applied for through steel deck welding or steel beam ceramic ferrule stud welding project. The ceramic ferrules are made of cordierite and able to withstand heat shock as well as high temperatures without melting or breaking.

It's necessary part for shear studs welding, designed with the following functions:

◇The ceramic ferrules make the shear studs welding connection point metal water easy forming, let the shear connectors with steel beam connect more solide and more tight

◇Prevent the damage of stud welder gun and welding gun components assemblage like stud chucks during the shear studs welding work.

◇To Reducing the arc welding spatter and smoke damage to workers

ceramic ferrules are produced as ISO13918:2008 standard with high hardness and High temperature resistant, can significant improve the weld result.

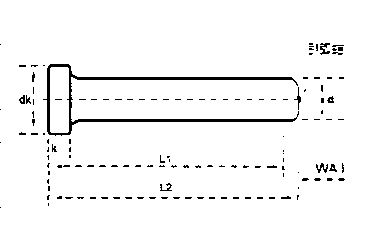

CYLINDER HEAD WELDING | |||||||

| BOLT DIMENSION | |||||||

| d | NOMINAL | 10 | 13 | 16 | 19 | 22 | 25 |

| MIN | 9.64 | 12.57 | 15.57 | 18.48 | 21.48 | 24.48 | |

| MAX | 10 | 13 | 16 | 19 | 22 | 25 | |

| dk | MAX | 18.35 | 22.42 | 29.42 | 32.5 | 35.5 | 40.5 |

| MIN | 17.65 | 21.58 | 28.58 | 31.5 | 34.5 | 39.5 | |

| d1 | 13 | 17 | 21 | 23 | 29 | 31 | |

| h | 2.5 | 3 | 4.5 | 6 | 6 | 7 | |

| k | MAX | 7.45 | 8.45 | 8.45 | 10.45 | 10.45 | 12.55 |

| MIN | 6.55 | 7.55 | 7.55 | 9.55 | 9.55 | 11.45 | |

| r | MIN | 2 | 2 | 2 | 2 | 3 | 3 |

| WA | 4 | 5 | 5 | 6 | 6 | 6 | |

Mechanical Properties Of Shear Stud Connector

| Country | Tensile strength | Yield point | Elongation percentage | Contraction percentage |

| BS EN ISO13918:2008 | ≥450 | ≥350 | ≥15 | |

| USA | ≥415 | ≥345 | ≥20 | ≥50 |

| CHINA | ≥400 | ≥320 | ≥14 | |

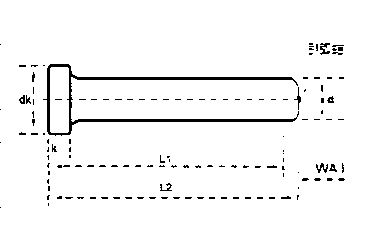

CYLINDER HEAD WELDING | |||||||

| BOLT DIMENSION | |||||||

| d | NOMINAL | 10 | 13 | 16 | 19 | 22 | 25 |

| MIN | 9.64 | 12.57 | 15.57 | 18.48 | 21.48 | 24.48 | |

| MAX | 10 | 13 | 16 | 19 | 22 | 25 | |

| dk | MAX | 18.35 | 22.42 | 29.42 | 32.5 | 35.5 | 40.5 |

| MIN | 17.65 | 21.58 | 28.58 | 31.5 | 34.5 | 39.5 | |

| d1 | 13 | 17 | 21 | 23 | 29 | 31 | |

| h | 2.5 | 3 | 4.5 | 6 | 6 | 7 | |

| k | MAX | 7.45 | 8.45 | 8.45 | 10.45 | 10.45 | 12.55 |

| MIN | 6.55 | 7.55 | 7.55 | 9.55 | 9.55 | 11.45 | |

| r | MIN | 2 | 2 | 2 | 2 | 3 | 3 |

| WA | 4 | 5 | 5 | 6 | 6 | 6 | |

Mechanical Properties Of Shear Stud Connector

| Country | Tensile strength | Yield point | Elongation percentage | Contraction percentage |

| BS EN ISO13918:2008 | ≥450 | ≥350 | ≥15 | |

| USA | ≥415 | ≥345 | ≥20 | ≥50 |

| CHINA | ≥400 | ≥320 | ≥14 | |

| Chemical Component Of Material (%) | ||||||

| Material | C | Si | Mn | P | S | Al |

| ML15AL | 0.13-0.18 | ≤0.10 | 0.30-0.60 | ≤0.035 | ≤0.035 | ≥0.020 |

| SWRCH18A | 0.15-0.20 | ≤0.10 | 0.60-0.90 | ≤0.030 | ≤0.035 | 1≥0.020 |

| Chemical Component Of Material (%) | ||||||

| Material | C | Si | Mn | P | S | Al |

| ML15AL | 0.13-0.18 | ≤0.10 | 0.30-0.60 | ≤0.035 | ≤0.035 | ≥0.020 |

| SWRCH18A | 0.15-0.20 | ≤0.10 | 0.60-0.90 | ≤0.030 | ≤0.035 | 1≥0.020 |

Main Benefits

1. Good concentricity and consistency.

2. Excellent wear and heat resistance.

3. High strength, endurability and anti-aging performance.

4. Extremely precise design as well as customized products.

Product Specification/Models

The steel structure column head jointing nails and ceramic protective or guard rings is formulated with cordierite.and by molding,vinegar,calcining,etc.The specification is as follows:Φ6,Φ8,Φ10,Φ13,Φ16,Φ19,Φ22 ordinary and penetrable etc.

Ceramic ferrule for unthreaded studs and threaded studs, such as UF, RF, RF-6, D1837, D0166, D0628, UF-12, M18, 6mm FD (Full Diameter), 8mm FD, 10mm FD, 8mm RB (Reduced Base), 10mm RB, 6mm Sprig FD

Application

This product is widely used for magnetic force floating railway engineer,building bridge,building railway,large power plant,plane depot that needs wide span.The steel structure column head jointing nails and ceramic protective or guard rings is formulated with cordierite.

Other Information

The main chemical ingredient of cordierite is 2MgO?2Al2O3?5SiO2, main material is steatite, clay, alumina, feldspar,etc. It is made by normal ceramic technique, such as dry press. They can be used for loop framework, insulators of arc-resistance, element of composite materials, burnable nozzle of electrical insulators,and etc

Main chemical ingredient:2MgO, 2Al2O3, 5SiO2

Bulk density :2.5gm/cc

Maximum use temperature:1800°C

Water absorption:0.1%

Hardness:800HV

Bending Strength:900Kgf/cm2 (20°C)

Compressive Strength:3500Kgf/ (20°C)

Coefficient of thermal expansion: ≤2.0(1×10-6/°C)

Dielectric constant: 6(1MHz.25°C)

Dielectric strength :10 ac-KV/mm(ac V/mil)

Volume Resistivity :>1012 ohm-cm(20°C)

Color: White, light yellow etc

Main Benefits

1. Good concentricity and consistency.

2. Excellent wear and heat resistance.

3. High strength, endurability and anti-aging performance.

4. Extremely precise design as well as customized products.

Product Specification/Models

The steel structure column head jointing nails and ceramic protective or guard rings is formulated with cordierite.and by molding,vinegar,calcining,etc.The specification is as follows:Φ6,Φ8,Φ10,Φ13,Φ16,Φ19,Φ22 ordinary and penetrable etc.

Ceramic ferrule for unthreaded studs and threaded studs, such as UF, RF, RF-6, D1837, D0166, D0628, UF-12, M18, 6mm FD (Full Diameter), 8mm FD, 10mm FD, 8mm RB (Reduced Base), 10mm RB, 6mm Sprig FD

Application

This product is widely used for magnetic force floating railway engineer,building bridge,building railway,large power plant,plane depot that needs wide span.The steel structure column head jointing nails and ceramic protective or guard rings is formulated with cordierite.

Other Information

The main chemical ingredient of cordierite is 2MgO?2Al2O3?5SiO2, main material is steatite, clay, alumina, feldspar,etc. It is made by normal ceramic technique, such as dry press. They can be used for loop framework, insulators of arc-resistance, element of composite materials, burnable nozzle of electrical insulators,and etc

Main chemical ingredient:2MgO, 2Al2O3, 5SiO2

Bulk density :2.5gm/cc

Maximum use temperature:1800°C

Water absorption:0.1%

Hardness:800HV

Bending Strength:900Kgf/cm2 (20°C)

Compressive Strength:3500Kgf/ (20°C)

Coefficient of thermal expansion: ≤2.0(1×10-6/°C)

Dielectric constant: 6(1MHz.25°C)

Dielectric strength :10 ac-KV/mm(ac V/mil)

Volume Resistivity :>1012 ohm-cm(20°C)

Color: White, light yellow etc