- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

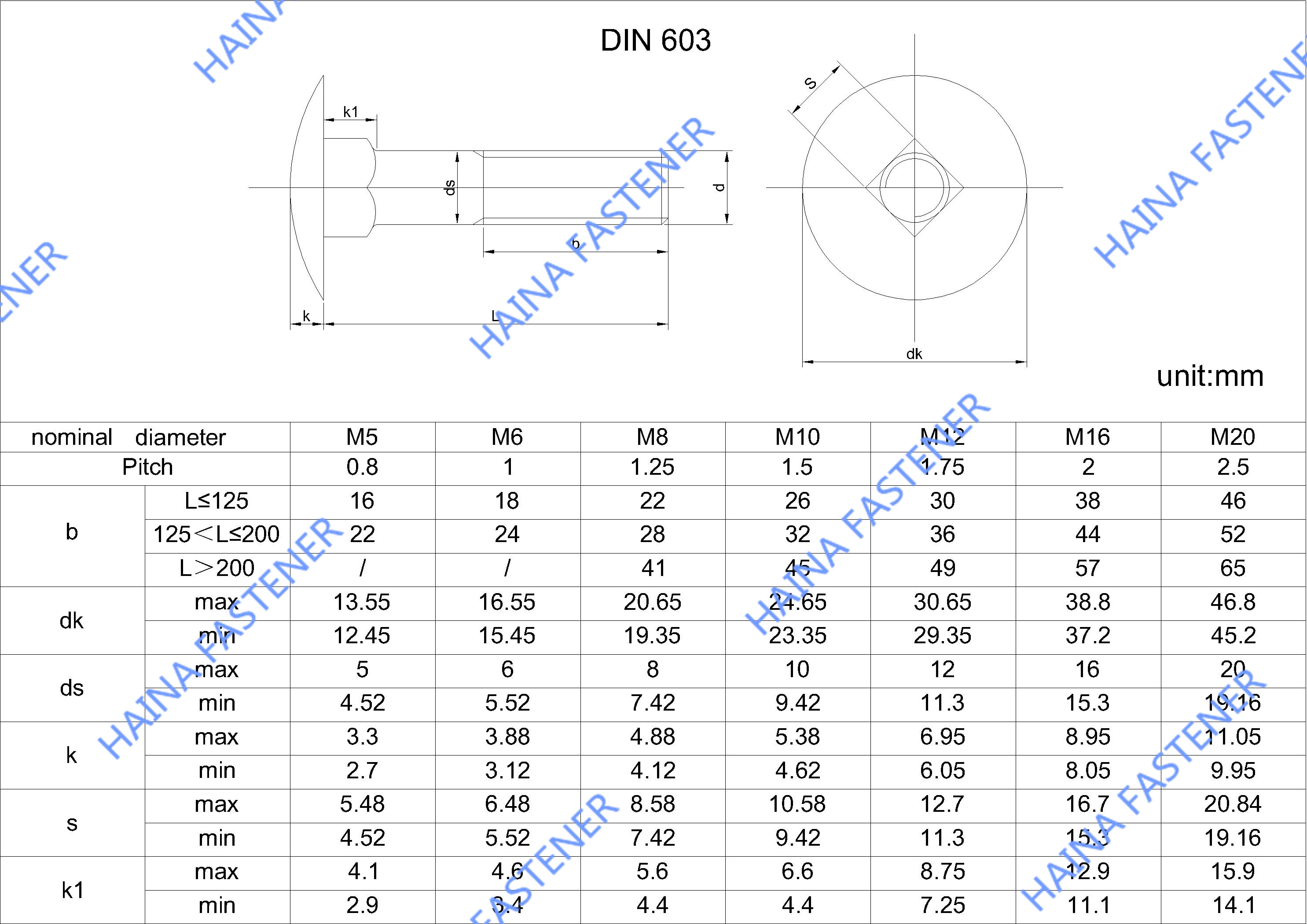

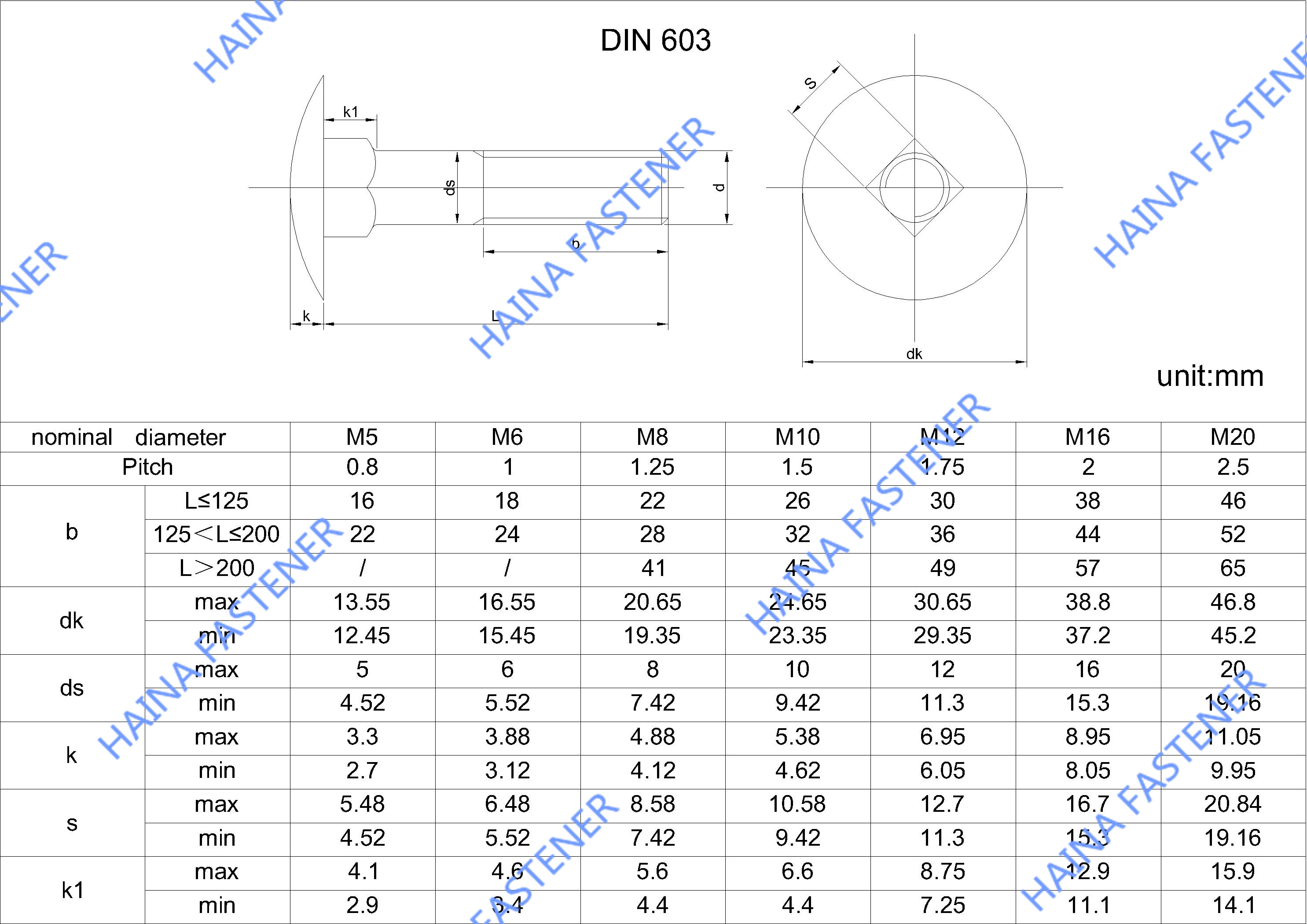

DIN603

HNF

HNF2024112201

Galvanised Round Head Square Neck Carbon Steel Coach Bolt

Product Description

Definition and structure

Galvanized coach bolts are also called square neck bolts. They have a round head and a square neck underneath. This special shape is designed to prevent the bolt from rotating with the nut during installation. When the coach bolt passes through the object to be fixed (such as wood, etc.), the square neck will be embedded in the material, playing a positioning role, so that the nut can be tightened smoothly.

Material characteristics

Galvanizing is a common surface treatment method for coach bolts. The galvanized layer can effectively prevent the bolts from rusting and corroding, extending their service life. This anti-rust performance is particularly important in outdoor environments or humid conditions, such as in construction, automobile manufacturing, agricultural machinery and other fields.

Product Details

Production Process

Product Application

In solar panel installation, coach bolts can be used to fix solar panel brackets to roofs or other supporting structures. Its sturdiness and anti-rotation characteristics ensure the stable installation of the bracket. In the field of woodworking, it is used to connect wood to build frames, such as making furniture, log houses, etc. In mechanical manufacturing, it can also be used to fix the casing of the machine or some parts that need to be frequently disassembled and installed.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.Why does the galvanized layer peel or fall off?

The reason may be that the surface treatment before galvanizing is not thorough, with oil, rust or oxide scale. The galvanizing process is not standardized, such as improper temperature control or insufficient time. The quality of the bolt material is rough or contains more impurities.

The solution is to strengthen the pre-plating treatment to ensure that the bolt surface is clean and smooth. Strictly control the galvanizing process parameters (such as temperature, zinc liquid composition, immersion time). Choose a bolt substrate with higher surface quality.

2.What is the solution for the rough or blistering surface of the galvanized layer?

The reason may be that the surface cleaning before galvanizing is not thorough, and there is oxide scale or pickling residue. The impurity content in the zinc liquid is too high, or the zinc liquid temperature is too high. The coating is contaminated during the cooling process.

The solution is to improve the surface cleanliness, especially the water washing and drying process after pickling. Regularly purify the zinc liquid to reduce the impurity content. Control the cleanliness of the cooling environment to avoid contamination.

3.What causes the sliding or loosening of the Coach bolt during installation?

The reason may be that the square neck is not fully embedded in the hole.

Solution: Make sure the diameter of the mounting hole matches the square neck. Use a tapping hammer or clamp to apply force to fully engage the square neck.

Galvanised Round Head Square Neck Carbon Steel Coach Bolt

Product Description

Definition and structure

Galvanized coach bolts are also called square neck bolts. They have a round head and a square neck underneath. This special shape is designed to prevent the bolt from rotating with the nut during installation. When the coach bolt passes through the object to be fixed (such as wood, etc.), the square neck will be embedded in the material, playing a positioning role, so that the nut can be tightened smoothly.

Material characteristics

Galvanizing is a common surface treatment method for coach bolts. The galvanized layer can effectively prevent the bolts from rusting and corroding, extending their service life. This anti-rust performance is particularly important in outdoor environments or humid conditions, such as in construction, automobile manufacturing, agricultural machinery and other fields.

Product Details

Production Process

Product Application

In solar panel installation, coach bolts can be used to fix solar panel brackets to roofs or other supporting structures. Its sturdiness and anti-rotation characteristics ensure the stable installation of the bracket. In the field of woodworking, it is used to connect wood to build frames, such as making furniture, log houses, etc. In mechanical manufacturing, it can also be used to fix the casing of the machine or some parts that need to be frequently disassembled and installed.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.Why does the galvanized layer peel or fall off?

The reason may be that the surface treatment before galvanizing is not thorough, with oil, rust or oxide scale. The galvanizing process is not standardized, such as improper temperature control or insufficient time. The quality of the bolt material is rough or contains more impurities.

The solution is to strengthen the pre-plating treatment to ensure that the bolt surface is clean and smooth. Strictly control the galvanizing process parameters (such as temperature, zinc liquid composition, immersion time). Choose a bolt substrate with higher surface quality.

2.What is the solution for the rough or blistering surface of the galvanized layer?

The reason may be that the surface cleaning before galvanizing is not thorough, and there is oxide scale or pickling residue. The impurity content in the zinc liquid is too high, or the zinc liquid temperature is too high. The coating is contaminated during the cooling process.

The solution is to improve the surface cleanliness, especially the water washing and drying process after pickling. Regularly purify the zinc liquid to reduce the impurity content. Control the cleanliness of the cooling environment to avoid contamination.

3.What causes the sliding or loosening of the Coach bolt during installation?

The reason may be that the square neck is not fully embedded in the hole.

Solution: Make sure the diameter of the mounting hole matches the square neck. Use a tapping hammer or clamp to apply force to fully engage the square neck.