- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

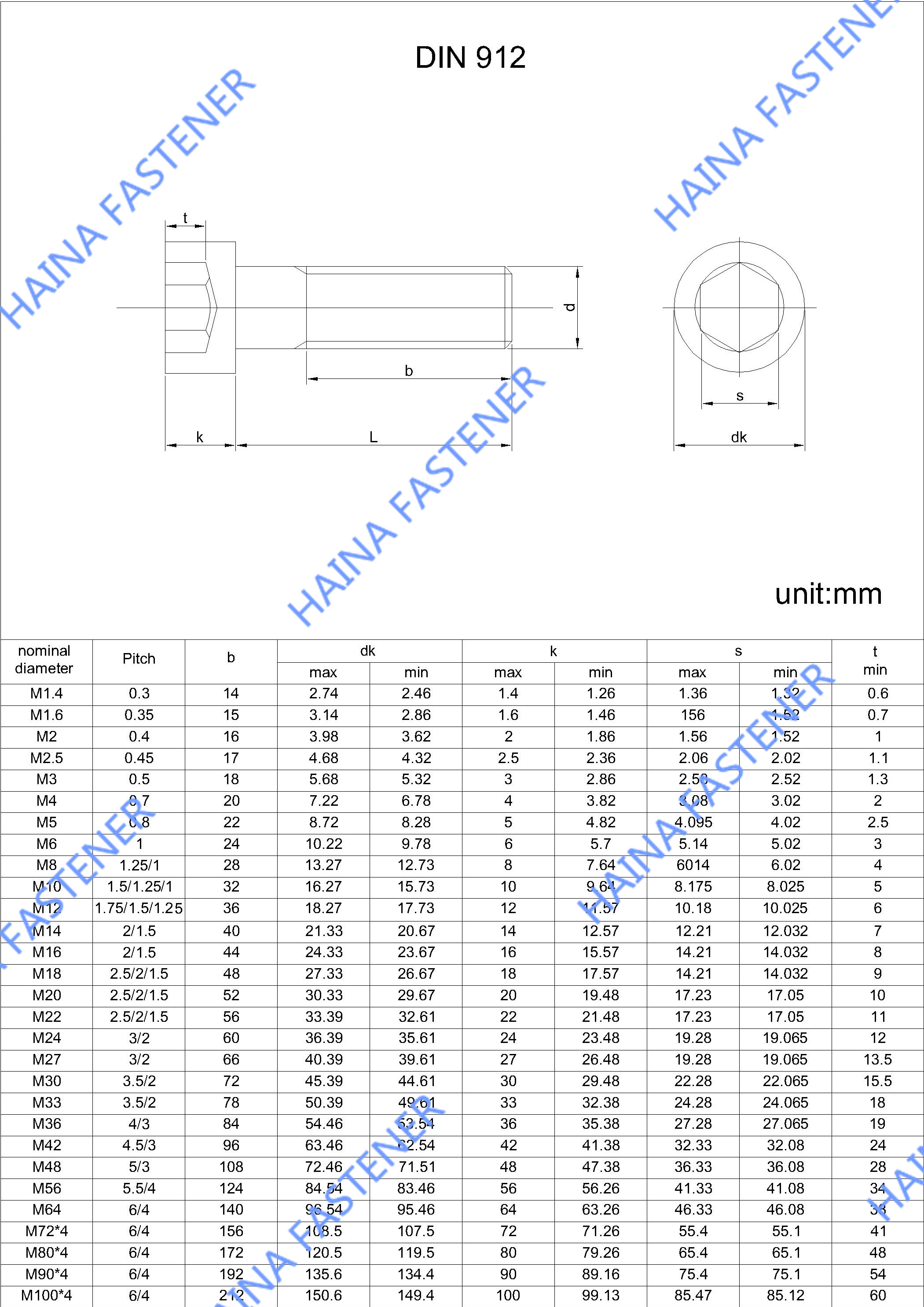

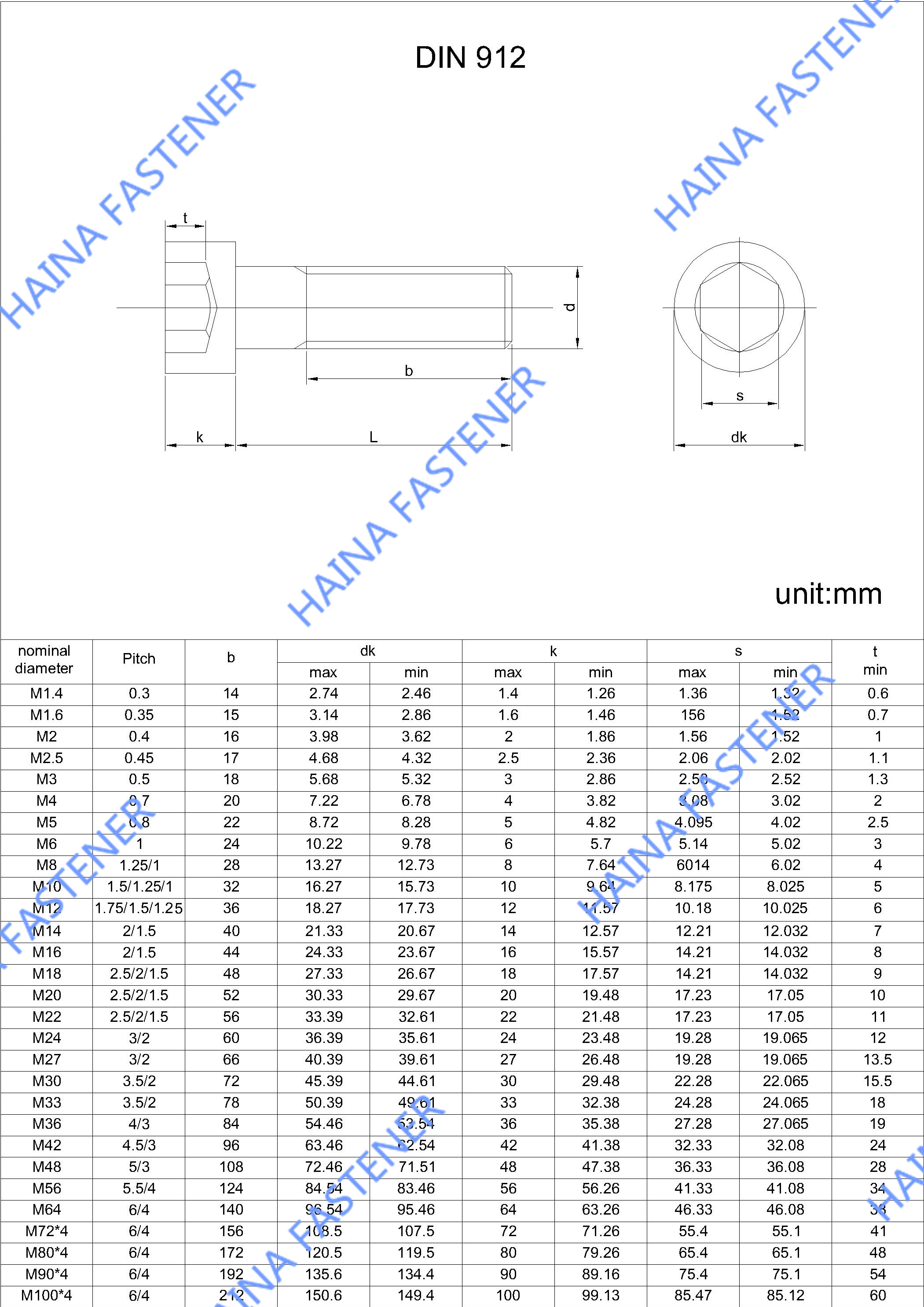

DIN912

HINA

2021121001

DIN912 Stainless Steel 304 316 M6 M12 Hexagon Socket Head Bolt

Product Description

Hexagon socket head bolt is a bolt head with a hexagonal groove, suitable for installation with an hexagonal wrench. It is usually used in applications that require high strength and tightening force, especially in places with limited space. Its hexagonal groove design increases the tool's grip, enabling higher torque control and making the connection more secure. Hexagon socket head bolts are widely used in industries such as machinery manufacturing, construction, automobiles and furniture assembly.

Advantages

1. High strength: The hexagonal design can withstand higher torque and provide a strong connection.

2. Space saving: The bolt head is small and suitable for small spaces.

3. Beautiful and neat: embedded installation, flat appearance, often used in places with high appearance requirements.

Disadvantages

1. Installation tool restrictions: An hexagonal wrench must be used, and the tool requirements are special.

2. Fragility: Frequent disassembly and assembly may damage the hexagonal slot and affect tool gripping.

3. Slightly higher cost: Compared with ordinary bolts, the manufacturing cost is slightly higher.

Product Details

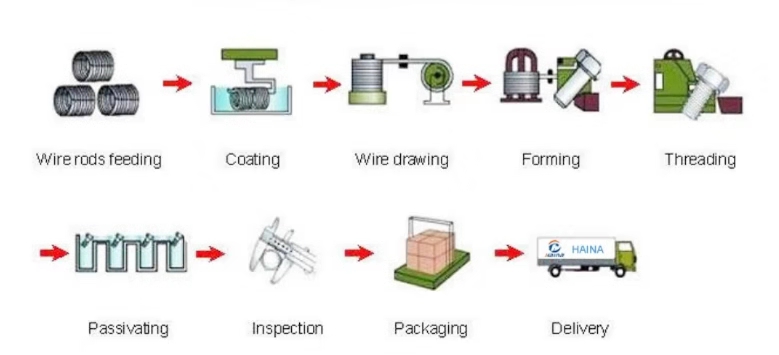

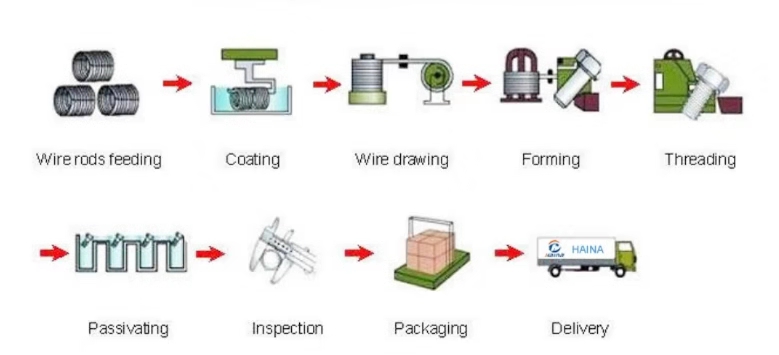

Production Process

Product Application

Hexagon socket bolts are widely used in places where high strength and tightening force are required, especially in places where space is limited and external wrenches cannot be used, such as precision equipment, engines and compact mechanical devices.

1. Mechanical manufacturing: used for high-strength and precision connections, such as machine tools, equipment structural parts, etc.

2. Automotive industry: used in parts such as engines and chassis that require high tightening force and vibration resistance.

3. Aerospace: used for important connections on aircraft and spacecraft because it saves space and provides high strength.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.Why are Allen bolts used?

The Allen bolt is widely used due to its unique hexagonal groove design. The main advantages include: Space saving: The bolt head is small and suitable for installation in places with limited space. High torque transmission: The hexagonal groove can withstand higher torque and provide a strong fastening effect. Convenient and beautiful installation: The groove design allows the head to be embedded in the material, and is often used in applications that require a smooth surface.

2.What is the difference between a hex head and socket head screw?

The difference between a hex head screw and a socket head screw lies mainly in the head structure and installation method. A hex head screw has an external hexagonal head and is operated with a wrench, which is suitable for larger spaces and general fastening needs; a socket head screw has an internal hexagonal slot in the head and requires a hexagonal wrench, which is suitable for applications with limited space or where the head needs to be hidden. Hex head screws are often used for heavier connections in construction and machinery, while socket head screws are more suitable for precision equipment and occasions with high aesthetic requirements. The characteristics of each make them play a role in different scenarios.

3.What is the difference between socket head and button head screws?

The difference between socket head screws and button head screws lies in the head shape and application occasions. The head of the hexagon socket screw is higher and the hexagonal groove is deep, providing higher torque, which is suitable for applications that require strong fastening, such as mechanical equipment. The head of the round head screw is low and smooth, which is suitable for occasions with high requirements for appearance and avoidance of protrusion and scratching, such as electronic equipment and furniture assembly. Hexagon socket screws are more suitable for high strength requirements, while round head screws are suitable for light connections and aesthetics.

DIN912 Stainless Steel 304 316 M6 M12 Hexagon Socket Head Bolt

Product Description

Hexagon socket head bolt is a bolt head with a hexagonal groove, suitable for installation with an hexagonal wrench. It is usually used in applications that require high strength and tightening force, especially in places with limited space. Its hexagonal groove design increases the tool's grip, enabling higher torque control and making the connection more secure. Hexagon socket head bolts are widely used in industries such as machinery manufacturing, construction, automobiles and furniture assembly.

Advantages

1. High strength: The hexagonal design can withstand higher torque and provide a strong connection.

2. Space saving: The bolt head is small and suitable for small spaces.

3. Beautiful and neat: embedded installation, flat appearance, often used in places with high appearance requirements.

Disadvantages

1. Installation tool restrictions: An hexagonal wrench must be used, and the tool requirements are special.

2. Fragility: Frequent disassembly and assembly may damage the hexagonal slot and affect tool gripping.

3. Slightly higher cost: Compared with ordinary bolts, the manufacturing cost is slightly higher.

Product Details

Production Process

Product Application

Hexagon socket bolts are widely used in places where high strength and tightening force are required, especially in places where space is limited and external wrenches cannot be used, such as precision equipment, engines and compact mechanical devices.

1. Mechanical manufacturing: used for high-strength and precision connections, such as machine tools, equipment structural parts, etc.

2. Automotive industry: used in parts such as engines and chassis that require high tightening force and vibration resistance.

3. Aerospace: used for important connections on aircraft and spacecraft because it saves space and provides high strength.

Company Services

Haina is committed to providing customers with high-quality stainless steel standard fasteners and professional services to meet various engineering needs. We have a large amount of spot inventory to ensure fast delivery and save you waiting time. In addition, we provide the following value-added services to help your purchasing experience:

1. Free samples: provide samples for customer testing.

2. 3.1 Test report: quality test report that meets international standards.

3. Video factory inspection: support video factory inspection to demonstrate production process and quality management.

Advantages

- Sufficient inventory: quick response to order requirements.

- Quality assurance: strict quality control to ensure product reliability.

Haina is committed to providing efficient and high-quality fastener services.

FAQ

1.Why are Allen bolts used?

The Allen bolt is widely used due to its unique hexagonal groove design. The main advantages include: Space saving: The bolt head is small and suitable for installation in places with limited space. High torque transmission: The hexagonal groove can withstand higher torque and provide a strong fastening effect. Convenient and beautiful installation: The groove design allows the head to be embedded in the material, and is often used in applications that require a smooth surface.

2.What is the difference between a hex head and socket head screw?

The difference between a hex head screw and a socket head screw lies mainly in the head structure and installation method. A hex head screw has an external hexagonal head and is operated with a wrench, which is suitable for larger spaces and general fastening needs; a socket head screw has an internal hexagonal slot in the head and requires a hexagonal wrench, which is suitable for applications with limited space or where the head needs to be hidden. Hex head screws are often used for heavier connections in construction and machinery, while socket head screws are more suitable for precision equipment and occasions with high aesthetic requirements. The characteristics of each make them play a role in different scenarios.

3.What is the difference between socket head and button head screws?

The difference between socket head screws and button head screws lies in the head shape and application occasions. The head of the hexagon socket screw is higher and the hexagonal groove is deep, providing higher torque, which is suitable for applications that require strong fastening, such as mechanical equipment. The head of the round head screw is low and smooth, which is suitable for occasions with high requirements for appearance and avoidance of protrusion and scratching, such as electronic equipment and furniture assembly. Hexagon socket screws are more suitable for high strength requirements, while round head screws are suitable for light connections and aesthetics.